Laser cutting services in Pune

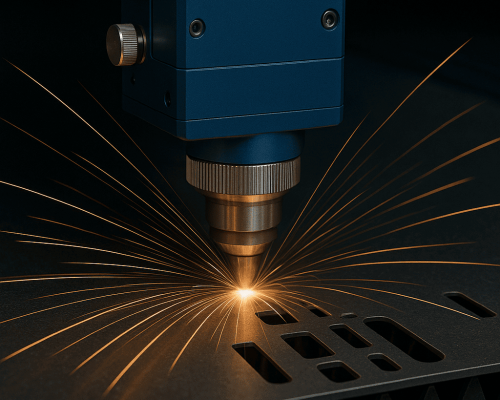

Precision laser cutting services in Pune. Cyclotron industries offers the most precise, fast and accurate laser cutting for your metal parts. With our high technology fiber laser cutting machine we tend to optimize the costing for each parts with less wastage and best throughput quality.

Laser cutting services in Pune

At Cyclotron, we offer our customers with the best in class sheet metal cutting facilities with our advanced HSG Laser cutting machines. Our team of experts can cut your metal parts of MS material along with SS, Aluminium, etc

- Achieve tight tolerances up to 0.1 mm for components that demand extreme accuracy.

- Equipped with state-of-the-art HSG laser cutting machines up to 6kW capacity.

- Fine, burr-free cutting ensures a smooth and flawless finish on every part.

- Quick turnaround of just 4 days, so your production timelines are never delayed.

- PAN-India delivery, ensuring safe and timely shipment of parts directly to your facility.

Best Laser cutting services by Cyclotron Industries. We offer high precision, fast and accurate laser cutting solutions for any kind of metal applications

- Fiber laser cutting is an industrial technology that utilizes the heat generated by a fiber laser to melt and remove material from a workpiece, resulting in a clean cut. The “laser” stands for Light Amplification Stimulated Emission of Radiation.

- Fiber laser technology utilizes a very narrow light beam directed at the target material. A moving optics system within the laser machine focuses the light.

- Metal laser cutting has become quite an indispensable service in Pune due to its ability to meet high precision and quality standards. The innovative technology has brought an enormous revolution, especially in the manufacturing and metal fabrication sectors.

- The integration of the CNC system with traditional metal cutting techniques has shifted the paradigm to a fully automated workflow.

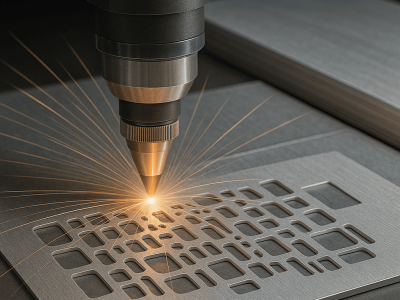

Modern laser cutters have simplified the process of creating intricate designs and patterns using high-beam lasers.

Precision laser cutting services in Pune

| Points | Description |

|---|---|

| Laser cutting machine power | 6 KW |

| Max sheet size | 1500*3000 mm |

| Max thickness | MS 25mm, SS 20mm, Al 18 mm |

| Repeatability | 0.005 mm |

| File format | DXF, DWG, STEP, IGES |

Cnc laser cutting services in Pune

Laser cutting is not a single technique. The choice of laser depends on the type of material and the thickness involved. At Cyclotron Industries, we provide specialized solutions using two advanced laser technologies:

1. Co2 laser cutting

- CO₂ laser cutting is one of the most widely used and cost-effective methods. It uses a carbon dioxide gas mixture to generate the laser beam.

- Best suited for non-metals such as wood, plastics, acrylics, and thin metals.

- Delivers smooth edges and high-quality surface finishes.

- Commonly applied in signage, crafts, decorative work, medical equipment, and aerospace components.

2. Fiber laser cutting

Fiber laser cutting uses fiber optics to amplify the laser beam and is known for its speed and efficiency.

Ideal for metals like stainless steel, aluminum, brass, and copper.

Offers faster cutting speeds, high precision, and low operating costs.

Widely used in aerospace, automotive, electronics, consumer goods, and construction industries where accuracy is critical.

CNC laser cutting services

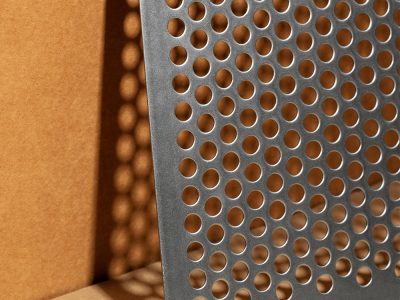

We specialize in sheet metal laser cutting across a range of materials, including mild steel (MS), stainless steel (SS), aluminum, etc. Our services are widely used in automotive sector, electrical panel manufacturing, construction equipment, agriculture machinery, and industrial enclosures. We also support custom laser cutting for R&D, prototyping, and small-batch runs.

We at Cyclotron Industries have stored material for fast turnaround and cutting times giving us an edge over our competitors with a very fast delivery timelines.

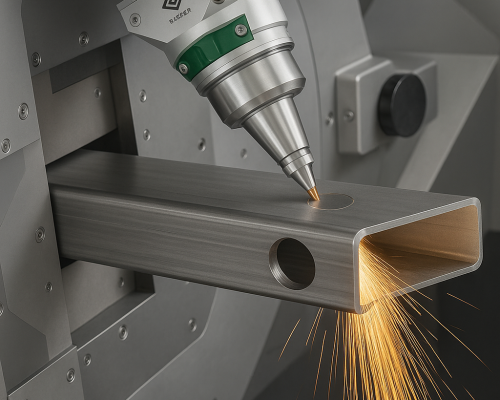

Best Pipe laser cutting in Pune by Cyclotron Industries. Get the best rates for Pipe and Tube laser cutting in Pune along with best cutting quality

Laser cutting by Material

Steel laser cutting technology allows clean and high-precision cutting while ensuring minimal HAZ (heat-affected zone) and material wastage.

This post discusses everything about aluminium laser cutting, including its applications, benefits, challenges, and strategies to improve its effectiveness. Stay tuned!

This post briefly discusses everything you need to know about SS laser cutting, its advantages, and applications of SS laser cutting, and much more.

Working of laser cutting

Laser cutting is a high-precision process used to shape metals and other materials. A focused laser beam is directed onto the surface, generating heat so intense that it melts or vaporizes the material along a defined path. The result is a smooth, accurate cut with minimal finishing required.

Modern CNC-controlled laser machines can handle a wide range of materials including mild steel, stainless steel, aluminum, copper, brass, galvanized iron, and several other alloys. This versatility makes laser cutting one of the most reliable methods for industrial fabrication today.

Cyclotron group clients

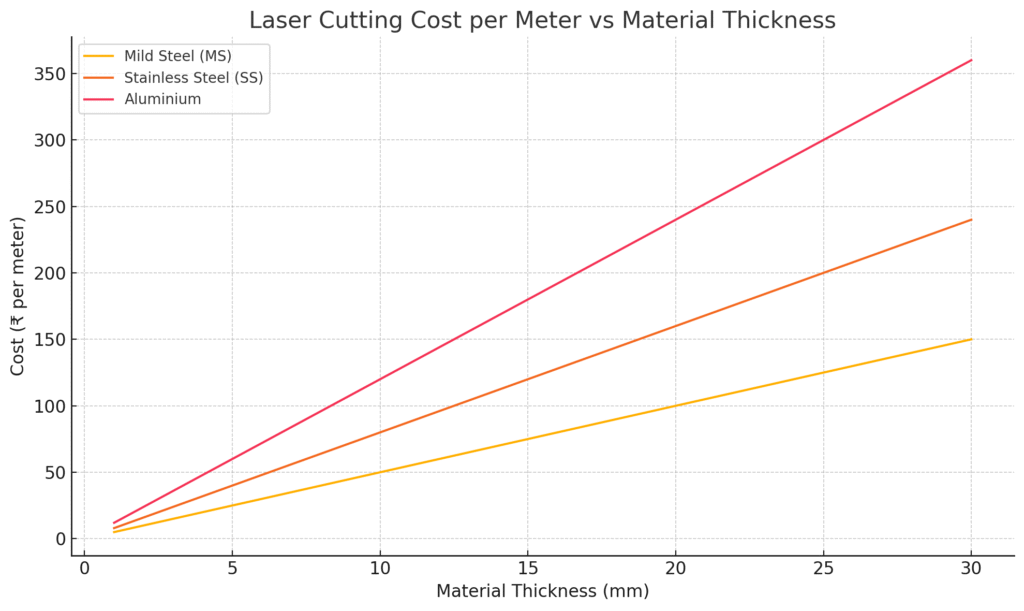

Laser cutting cost in Pune

Laser cutting cost in Pune is Rs 5-10 per meter per mm, It will cost Rs 5-10 for 1 meter length of 1 mm material. Similarly will cost Rs 10-20 for 1 meter length of 2 mm material.

Laser cutting costs in India depend on the material used, its thickness, the type of machine (fiber or CO₂), and the level of detail required for the job.

Small orders usually cost more per piece, while bigger orders bring down the price. Additional charges may apply for design setup, finishing, or delivery.

Best Laser cutting services by Cyclotron Industries. We offer high precision, fast and accurate laser cutting solutions for any kind of metal applications

Advantages of Laser cutting

Among the many methods available for metal processing, laser cutting continues to stand out as one of the most trusted and widely used techniques. Even with the arrival of newer technologies, laser cutting remains highly relevant because of the advantages it offers.

- 1. Precision at its Best: A laser beam concentrates heat on a very small area, allowing cuts with extremely tight tolerances. This level of accuracy makes it possible to produce fine details, sharp edges, and complex shapes that would be difficult to achieve with conventional tools.

- 2. Faster Cutting Speeds: Laser machines operate at high speed, reducing lead times and improving overall productivity. Projects that would take longer with mechanical methods can be completed in a fraction of the time.

- 3. Reduced Material Waste: Since the process is non-contact, there is minimal tool wear and almost no material deformation. The computer-controlled system ensures maximum material utilization, which also cuts down on post-processing costs and time.

- 4. Versatility Across Materials: Laser cutting is not limited to one type of metal. It works effectively on stainless steel, aluminum, copper, brass, and galvanized iron. It can also be used on non-metallic materials such as acrylic, making it useful for a wide range of industries.

Cyclotron's expertise in Laser cutting services

At Cyclotron Automation, we have worked in the field of fabrication and welding automation for more than a decade. This experience has given us a deep understanding of what manufacturers and OEMs expect when it comes to consistency and quality.

Building on this foundation, we have expanded into Cyclotron Industries, where our focus is on precision laser cutting services tailored for Pune’s manufacturing ecosystem. With in-house developed equipment and advanced CNC technology, we deliver laser cutting solutions that combine accuracy, efficiency, and reliability.

Our services are designed to support OEMs, suppliers, and fabricators across sectors. Each project is handled with attention to detail so that the final output aligns perfectly with the client’s requirements.

FAQs about Laser cutting

- What is your lead time for laser cutting? Our standard lead time is around 3-4 days for customers in Pune region.

- What types of metal can you cut using laser cutting? We can cut Mild steel (upto 25mm), Stainless steel (upto 20mm), Aluminium (Upto 18 mm)

- What is the maximum sheet size you can process? Our bed size if 1500x3000mm so we can process max upto this size.

- How accurate are your laser cutting services? We offer tight tolerances upto 0.1mm and repeatability of 0.05mm consistent

- Do you serve only in Pune or PAN India? While our facility is based in Pune, we provide services PAN India and take care of all the logistics and support.

- Do you provide inspection and quality report? Yes we provide PDI reports with all the material that we dispatch on daily basis.

Why is laser cutting profound in Pune?

Pune has earned its place as one of India’s strongest industrial hubs. The city is home to leading automotive companies, aerospace facilities, large-scale engineering firms, and a growing logistics and warehousing ecosystem. Each of these industries relies heavily on components that demand accuracy, durability, and consistent quality.

Laser cutting provides the speed, precision, and repeatability that these industries need. Whether it’s a small batch of custom parts or large production runs, the process ensures that every cut matches the exact specifications of the design.

Best Laser cutting services by Cyclotron Industries. We offer high precision, fast and accurate laser cutting solutions for any kind of metal applications

Laser cutting services

Laser cutting services in Pune

Fiber laser cutting services in Pune

Metal laser cutting services in Pune

Laser cutting for sheet metal parts

CNC Laser cutting services in Pune