Steel laser cutting services

Steel laser cutting services in Pune

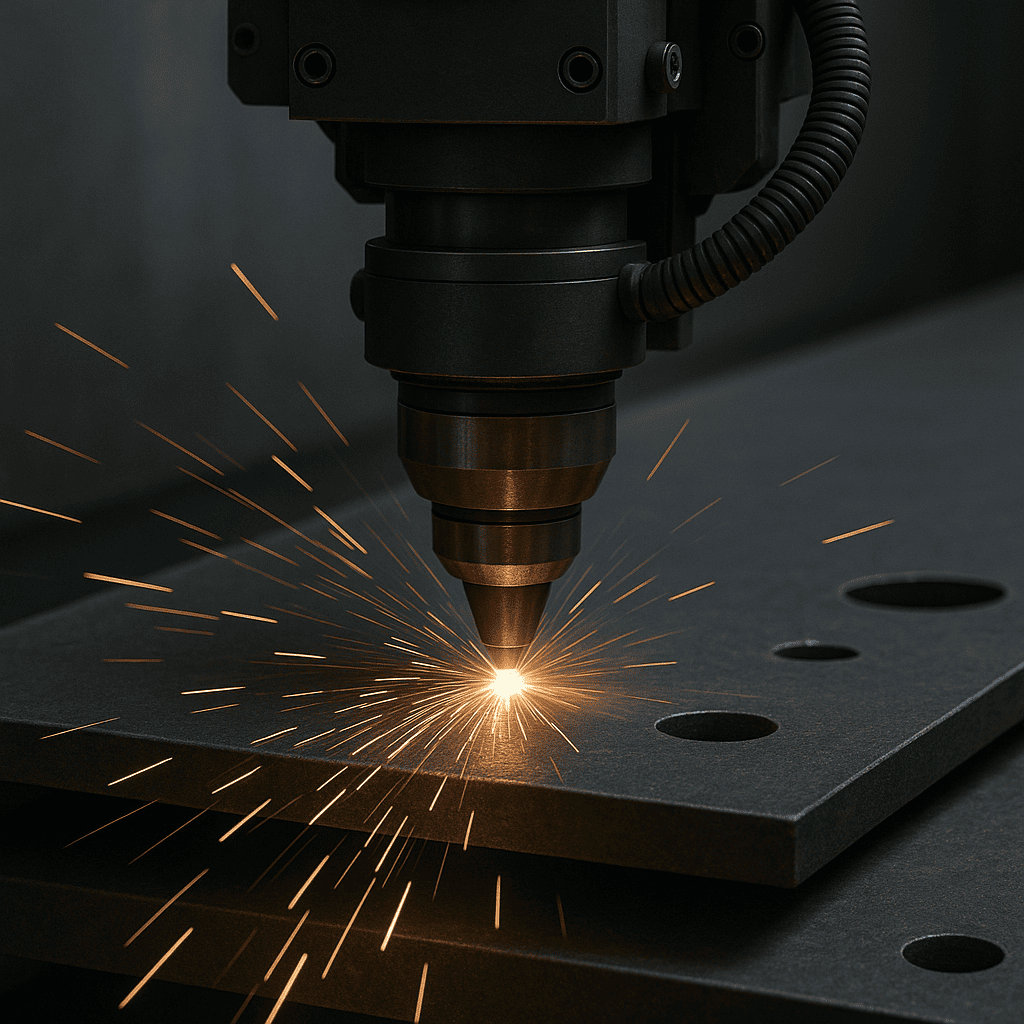

Cyclotron Industries is the leading Steel Laser Cutting Services in Pune. Trusted by OEMs for Laser cutting in Pune. Mild steel laser cutting services with the most affordable rates without comprising of the metal cutting quality.

Looking for advanced steel laser cutting services in Pune to boost productivity and efficiency? Don’t rush!

- We recommend reading this expert’s guide to learn about different types of Steel material and steel laser cutting operations. Steel laser cutting technology allows clean and high-precision cutting while ensuring minimal HAZ (heat-affected zone) and material wastage.

Steel is one of the most cost-effective and reliable materials used by almost every industry to produce basic to complex metal components.

Interesting? Stay tuned to know how MS laser cutting can benefit your business in the long run…….

Best Laser cutting services by Cyclotron Industries. We offer high precision, fast and accurate laser cutting solutions for any kind of metal applications

Introduction to Steel Laser Cutting

- Laser cutting has become crucial in the manufacturing industry for a wide range of metals and non-metals. Steel (carbon steel/ stainless steel) is among the most common yet valuable materials used in laser cutting operations for crafting fabricated components

- Steel laser cutting services have redefined excellence in agriculture, railways, automotive, and various other sectors. Growing demand for precision steel laser cutting in fabrication and manufacturing requires robust quality protocols and skilled operators.

- Read this blog to know everything about stainless steel laser cutting and mild steel laser cutting services to boost business growth and productivity.

- Steel is a valuable material for manufacturing industries due to its ability to create intricate designs and perform under varying conditions. MS laser cutting is a non-contact, CNC-controlled process that focuses an intense laser beam (fibre/CO2) on a small spot of steel material. This fine-tuned cutting process is based on the principle of melting & vaporizing the workpiece, followed by the ejection of assist gas. Different types of steel materials are available in the market, including

- Mild steel / Carbon Steel

- Stainless steel

- Alloy steels

- Although there are other traditional methods like plasma and oxy-fuel to cut steel, steel laser cutting is preferred nowadays. Here’s the quick comparison of all these cutting techniques.

| Feature | Laser cutting | Plasma cutting | Oxy-fuel Cutting |

|---|---|---|---|

| Steel thickness (max.) | Up to 1 inch | Up to 2 inch | Above 12 inches |

| Precision | High | Medium | Low |

| Speed | Faster on thin sheets | Fast on thick sheets | Slow |

| Principle | Thermal | Thermal / Electrical | Chemical |

Besides being only a cost-effective material, Steel offers multiple benefits in MS laser cutting operations. Take a look!

1.High Precision and Accuracy

It is one of the best features that has attracted various industries (automotive, construction, defense, etc.) to rely on steel laser cutting services.

2.Clean Edges with Minimal Burr

Laser cutting of steel parts is performed with the ejection of Nitrogen or oxygen gas, thus delivering clean Edges with minimal burr and HAZ (heat-affected zone).

3. Faster Cutting Speed and Efficiency

The exceptionally high-speed steel laser cutting process helps boost overall productivity, especially for large-volume productions.

4. Capability to Cut Complex Shapes

Steel laser cutting offers an unmatched level of precision for metal parts with complex designs, shapes, and patterns.

5. Cost-effective for Small and Large Batches

High versatility and automated nature make steel laser cutting ideal for prototype and mass production.

Steel Laser Cutting Process Explained

It uses optics and a CNC-controlled system to create metal components while maintaining speed, accuracy, and consistency. The pre-programmed CNC system moves the laser head to the specific path. The metal laser cutting procedure typically involves:

1.Design & CAD/CAM programming: In the initial phase, a design file is created using CAD/ CAM software. The software is then converted into G-code, which contains the laser path and design.

2. Material setup and thickness considerations: The metal sheet is loaded into the laser cutter while the operator adjusts other performance parameters (speed, power, focal length, etc.)

3. Cutting operation: This phase involves generating a Laser beam using a CO2 or fiber laser and focusing on the surface of the metal sheet. The concentrated laser beam heats, melts, and vaporises the metal until the desired cut is obtained. Finally, an assist gas (oxygen/ nitrogen) is ejected to blow away the burr from the edges.

4. Inspection & quality checks: The final metal part is thoroughly inspected for quality in accordance with global industry standards. Most often, laser cutting doesn’t require any additional processes, such as anodizing or heat treatment.

Steel material is highly versatile, durable, and delivers precise results when used for various laser cutting operations. That’s why steel is one of the most popular yet cost-effective materials for laser cutting operations. Below are some key applications of steel laser cutting.

1.Construction & Infrastructure Projects

This sector relies on high-precision steel laser cutting services for cutting thick metal plates, beams, bridges, and other heavy structural components.

2.Automotive & Heavy Equipment Parts

Steel laser cutting is the primary method for this industry to manufacture vehicles, interiors, chassis components, or rapidly prototype components.

3.Aerospace & Defense Components

Precision cutting of air panels, light alloys, and other composite materials is all possible through steel laser cutting services.

4.Industrial Machinery & Fabrication

Agricultural equipment, complex machinery parts, enclosures, and other components are manufactured using steel laser cutting.

5.Architectural & Decorative Products

Custom metal signs, decorative furniture, signage, and innovative designs are some significant applications of steel laser cutting.

Types of Steel Suitable for Laser Cutting

Steel, being a cost-effective and anti-corrosion material, is widely deployed in manufacturing industries for producing laser-cut metal components. Here is the list of different types of steel material that you can choose from, depending on your business requirements.

1. Mild Steel (MS): Mild steel, or carbon steel, is affordable and offers high strength, making it ideal for construction and automotive parts. Mild steel gives the best results when cut with oxygen gas.

2.Stainless Steel (SS304, SS316, etc.): Laser cutting followed by ejection of Nitrogen gas produces stainless steel components with high precision, clean cuts, and smooth finishing.. SS is ideal for chemical and medical industries operating at high temperatures.

3. Galvanized and Coated Steels: Galvanized steel offers anti-corrosion properties and is perfect for outdoor applications such as vehicle outer bodies and car panels.

Factors Affecting Steel Laser Cutting Cost

Besides fixed expenses like machine investment, overhead, and labor, the steel Laser cutting cost depends on various factors. Take a look at the key cost factors!

1.Material thickness and grade: The thicker the material, the more power will be consumed, and the longer the total machine running time will be. In short, the cost increases with the thickness of the steel material.

2. Part complexity: Complex steel parts with more edges and holes take more time & power to cut, which obviously adds to the overall laser cutting cost.

3. Batch volume: The cost for mass production is significantly lower than that of prototype or small batch jobs. The setup and programming costs are distributed across multiple units.

4. Laser power: Typically, 2kW, 4kW, and 6kW fiber lasers are used in steel cutting operations. High-power lasers perform significantly faster than lower-power lasers, which increases the turnaround times while reducing the cost.

Best Laser cutting services by Cyclotron Industries. We offer high precision, fast and accurate laser cutting solutions for any kind of metal applications

FAQs on Steel Laser Cutting Services

1.What is the maximum thickness a laser can cut in steel?

High-powered fiber lasers can cut steel with a maximum thickness of up to 30 mm. For instance, a 2KW fiber laser can handle a thickness of 20mm for carbon steel, 8mm for stainless steel, and 6mm for aluminium.

2. Is laser cutting suitable for stainless steel?

Yes, laser cutting is the most precise and accurate method for creating complex designs with stainless steel. In addition, it also helps minimize heat-affected zones while maintaining material integrity.

3. Does laser cutting affect steel’s structural integrity?

Laser cutting may create high-heat-affected zones, which may change the material properties. The high HAZ can increase the hardness level.

4. How do I get a quote for steel laser cutting services?

All you need to do is visit the website offering MS laser cutting, upload the design file, select the material, and quantity as per your requirement. Or, you can directly contact Cyclotron Industries for steel laser cutting in Pune or across India.

Laser cutting services

Laser cutting services in Pune

Fiber laser cutting services in Pune

Metal laser cutting services in Pune

Laser cutting for sheet metal parts

CNC Laser cutting services in Pune