Stainless steel laser cutting in Pune

Stainless steel laser cutting in Pune

Precise Stainless steel Laser cutting in Pune by Cyclotron Industries. We have expert team for laser cutting solutions for MS, SS, Aluminium. Cyclotron is a Industry leader in all types of Metal cutting services.

Stainless steel laser cutting

Stainless steel is taking centre stage in modern fabrication thanks to its strength, corrosion-resistance, and sleek appearance. When precision matters, SS laser cutting has emerged as a go-to method for fabricators and manufacturers alike.

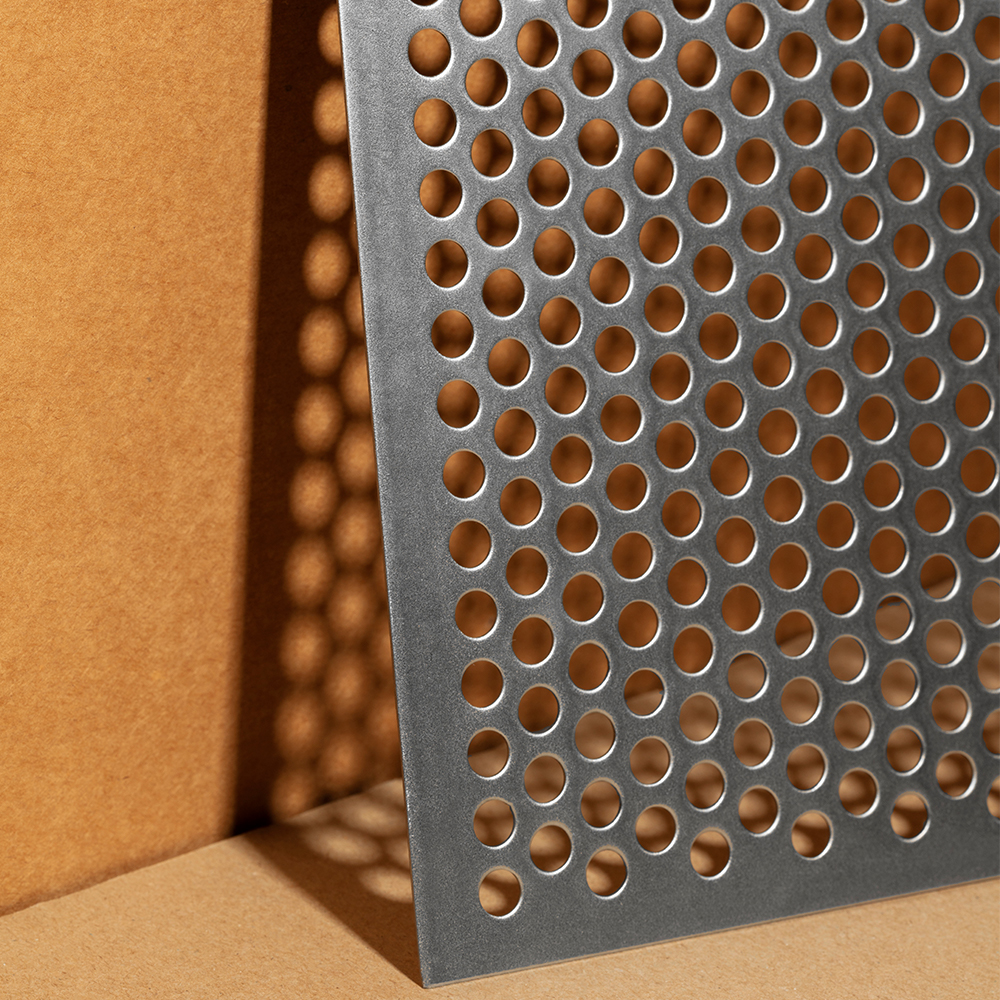

Whether you need complex patterns in an architectural panel or high-accuracy parts for machinery, SS laser-cutting services deliver clean, reliable results.

When working with flat sheets, SS sheet laser cutting offers a fast, accurate way to transform raw material into finished components with minimal fuss. In a world where speed and quality count, this technology is quietly reshaping how we cut and fabricate.

This post briefly discusses everything you need to know about SS laser cutting, its advantages, and applications of SS laser cutting, and much more.

Best Laser cutting services by Cyclotron Industries. We offer high precision, fast and accurate laser cutting solutions for any kind of metal applications

Introduction to SS Laser Cutting

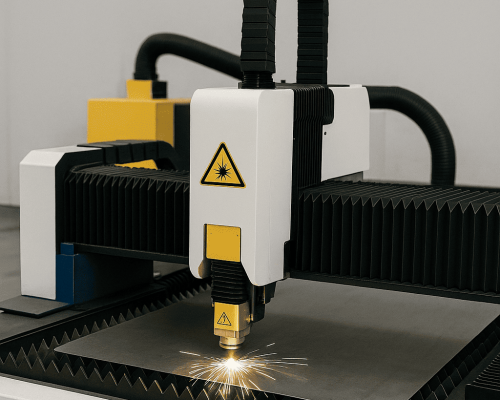

- Stainless steel (SS) laser cutting is a modern, reliable method for cutting stainless steel sheets with outstanding precision. Using focused laser beams, it creates smooth edges, detailed shapes, and minimal material waste.

- This method is widely used across industries such as architecture, automotive, and manufacturing because it delivers fast, accurate, and consistent results that traditional cutting methods can’t match.

Advantages of SS Laser Cutting Services

- High Precision and Accuracy: One of the most vital benefits of SS laser cutting is the exceptional precision it offers. The laser beam is extremely narrow and highly focused, so you can cut intricate shapes, maintain tight tolerances, and achieve fine features—even in thicker sheets and without significant deviations. This is ideal when you require consistent part-to-part repeatability or when the end use demands high accuracy (for example, in industrial machinery, aerospace components, or architectural fittings).

- Clean, Burr-Free Edges: When you cut stainless steel mechanically (such as shearing or sawing), you often end up with burrs (tiny rough bits of metal) or irregular edges. Laser cutting, by contrast, produces immaculate cuts with minimal burr formation. That means less time spent on deburring or grinding and fewer risks of edge defects or sharp metal fragments in your finished component.

- Smooth Finish Without Polishing: Because the laser melts or removes the steel rather than shears it mechanically, the cut face often exhibits a smooth finish straight off the machine. In many cases, you won’t need additional polishing or heavy finishing to achieve a visually appealing edge or functional surface. That saves time, labour, and cost.

- No Material Deformation or Warping: The thermal input from a laser is relatively focused, and the cut zone is small; the surrounding material is less likely to warp, distort, or suffer from heat-affected zone (HAZ) issues. That matters especially when you’re working with heat-sensitive stainless-steel grades, or when the part has thin walls or fine features where any warping would compromise fit or function.

- Efficient for Small and Large Batches: Whether you’re running one-off prototypes or large-volume production, SS laser cutting services scale well. The setup time (once the file is programmed) is minimal compared with tooling or mechanical setup, and the repeatability means you can ramp volumes reliably. For bespoke one-off jobs, you can get a fast turnaround; for production runs, you can cut many parts quickly, consistently, and with minimal manual intervention.

Best Laser cutting services by Cyclotron Industries. We offer high precision, fast and accurate laser cutting solutions for any kind of metal applications

Applications of SS Laser Cutting Services

- Automotive and Transport Components: In the automotive and transport sector, components such as brackets, engine guards, exhaust system parts, structural supports, and decorative metalwork often utilize stainless steel. With SS laser cutting, manufacturers can produce accurate, repeatable parts that meet strict tolerances while maintaining performance and finish quality.

- Food Processing & Pharma Equipment: Stainless steel is a staple material in food processing and pharmaceutical equipment due to its hygienic properties, ease of cleaning, and corrosion resistance. Laser-cut stainless steel sheets and plates are used for equipment frames, housings, panels, conveyor components, and enclosures, all of which benefit from the precision and minimal surface damage of laser cutting.

- Industrial Machinery & Fabrication: For industrial machinery (pumps, valves, gearboxes, structures) and general fabrication, SS laser cutting delivers the speed and accuracy needed to produce parts quickly while maintaining quality. Whether one-off custom components or medium-volume runs, fabrication shops appreciate the flexibility and reduced finishing work.

- Decorative Panels & Architectural Work: Architects and fabricators are increasingly using laser-cut stainless steel for a variety of applications, including decorative screens, façades, signage, stair treads, interior metal panels, and sculptural elements. Laser cutting of stainless-steel sheets allows for fine detail, clean edges, and design flexibility, all while producing a professional finish.

SS Laser Cutting vs Other Cutting Methods

| Parameter | Laser Cutting (SS) | Plasma Cutting (SS) | Waterjet Cutting | Mechanical Shearing |

|---|---|---|---|---|

| Cutting Precision | Extremely high (±0.1 mm tolerance) | Moderate (±0.5 mm) | High (±0.2 mm) | Low to moderate |

| Edge Quality | Smooth, burr-free, ready-to-use | Rough edges, may need finishing | Clean, minimal burrs | Burrs and deformation possible |

| Heat-Affected Zone (HAZ) | Very small due to focused beam | Large, can cause warping | None (cold cutting) | Moderate, depending on thickness |

| Speed | Very fast for thin & medium sheets | Fast for thicker plates | Slower process | Fast for straight cuts only |

| Complex Shapes & Designs | Excellent – ideal for intricate geometry | Limited detail capability | Good, can cut any shape | Poor – mostly straight lines |

| Material Thickness Range | Best for thin to medium (0.5 – 25 mm) | Best for medium to thick (3 – 50 mm) | Very thick materials (up to 200 mm) | Thin to medium sheets |

| Surface Finish Quality | Smooth, often no polishing required | Requires grinding/polishing | May need light finishing | Requires heavy finishing |

| Material Deformation | Minimal | Possible due to heat | None | Common in thin sheets |

| Setup & Tooling | Quick digital setup, no tooling | Moderate setup | Moderate | Requires physical tooling/blades |

| Operational Cost | Moderate; efficient for batches | Lower for heavy cuts | High (abrasive + water cost) | Low per cut but limited flexibility |

| Environmental Impact | Clean, minimal waste | High fume generation | Requires water disposal | Generates scrap and noise |

| Best Use Cases | Precision fabrication, stainless steel, complex parts | Heavy fabrication, thick steel | Multi-material cutting, no heat zones | Basic sheet trimming, straight cuts |

Why Choose Cyclotron for SS Laser Cutting Services

At Cyclotron, we make stainless steel (SS) cutting simple, accurate, and efficient. We are one of the top laser cutting companies in India.

- Advanced Machines: We use high-power CNC fiber laser machines made especially for cutting stainless steel. These machines provide smooth, clean, and accurate cuts every time.

- Expert Team: Our skilled dedicated professionals can cut both thin sheets and thick plates with equal precision. Whether your project is small or large, we handle it out perfectly.

- High-Quality Finish: The laser-cutting process delivers a smooth, precise edge, so there’s no need for additional polishing or finishing afterward.

- Fast and Reliable Service: We offer quick turnaround times to help you meet deadlines. Being based in SS laser cutting in Pune, we also provide fast local support whenever you need it.

Best Laser cutting services by Cyclotron Industries. We offer high precision, fast and accurate laser cutting solutions for any kind of metal applications

Laser cutting services

Laser cutting services in Pune

Fiber laser cutting services in Pune

Metal laser cutting services in Pune

Laser cutting for sheet metal parts

CNC Laser cutting services in Pune