Safety measures in laser cutting operations

Safety measures in laser cutting operations

Top 7 Safety measures in laser cutting operations are Use of PPE, Proper machine guards, Ventilation, Material handling safety, fire prevention, electrical safety, emergency stop.

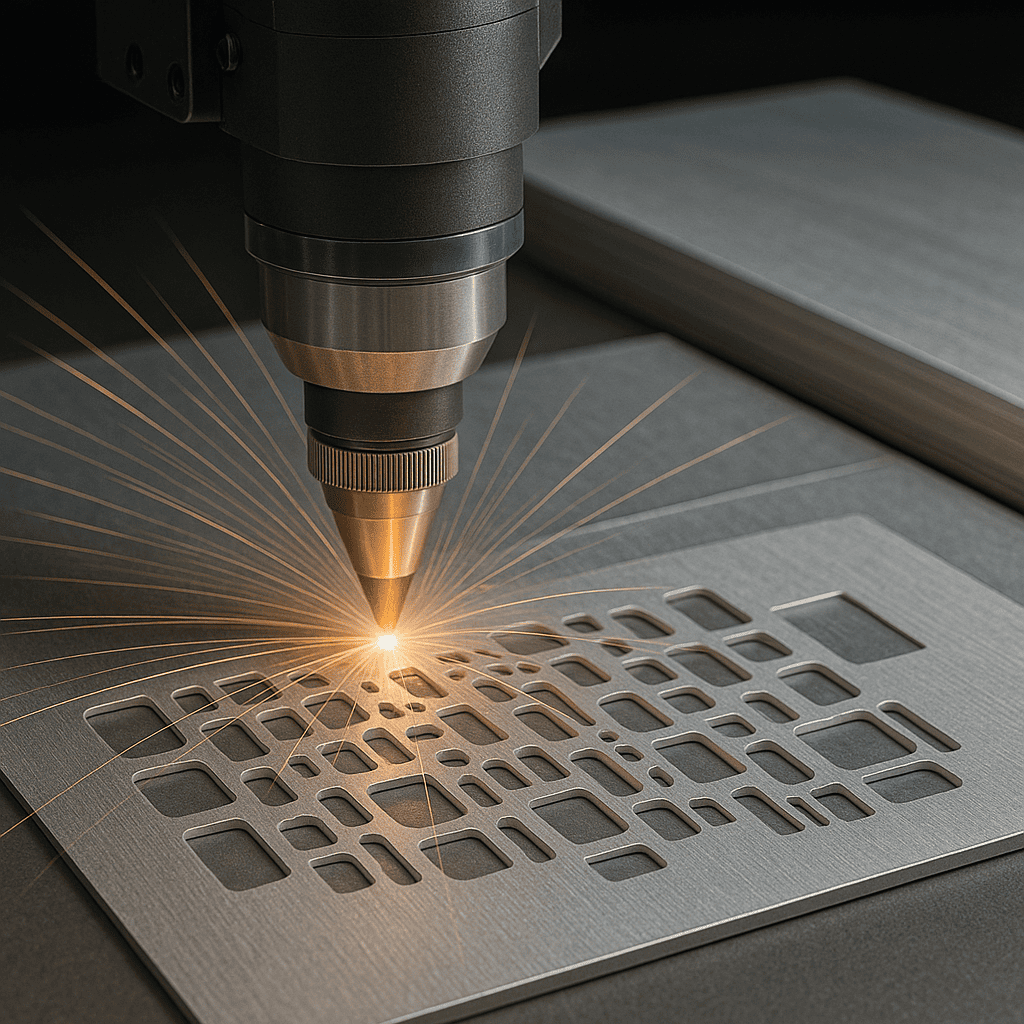

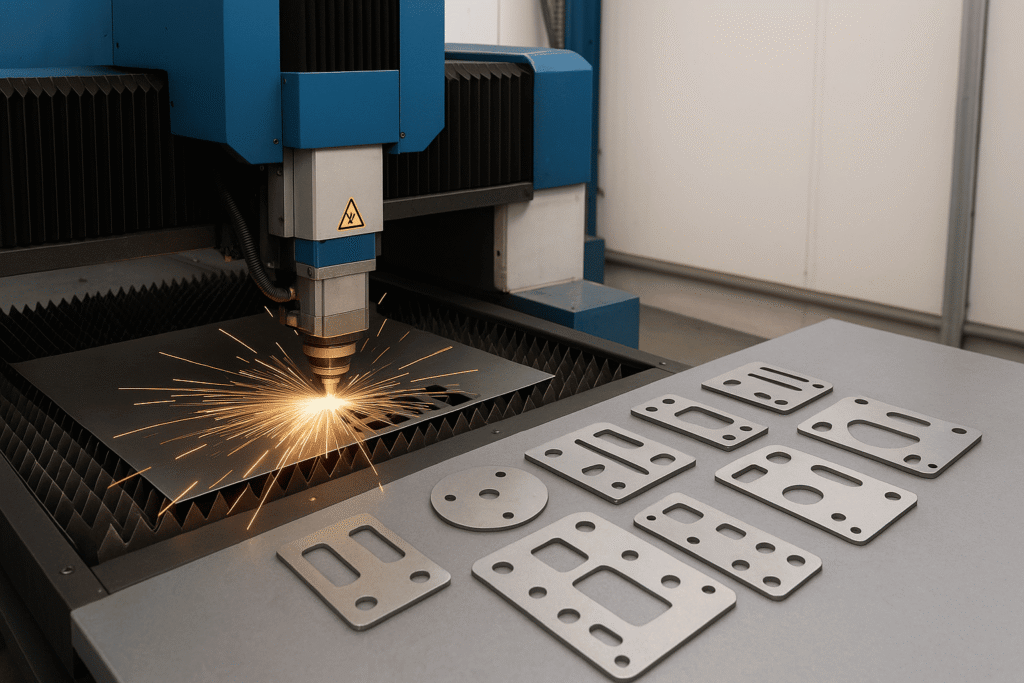

Laser cutting brings speed, accuracy, and flexibility to modern manufacturing, but it also brings significant hazards that demand respect and strict controls. High-power beams, intense heat, and rapidly moving automation create risks ranging from burns and fires to hazardous fumes and electrical faults.

Whether you run a small job shop or manage a high-volume production line, understanding the practical safety measures in laser cutting operations protects your people, preserves equipment, and keeps production running reliably.

This guide is written for operators, supervisors, and safety officers who want clear, actionable steps to reduce risk and comply with standards. Read this as a practical checklist and training reference: follow engineering controls first, back them up with administrative procedures, and always use the right PPE. Safety saves lives and assets and reduces operational disruption daily.

Best Laser cutting services by Cyclotron Industries. We offer high precision, fast and accurate laser cutting solutions for any kind of metal applications

Why Laser Cutting Safety Matters?

- Laser systems used in fabrication range from lower-power units to industrial lasers, commonly between 2 kW and 12 kW.

- These powerful beams can cause severe eye and skin injuries if not properly contained. Beyond beam hazards, cutting processes generate intense heat, sparks, and molten slag that can ignite nearby materials.

Fumes from cutting certain metals and coatings may be hazardous to breathe. Electrical systems and moving gantries add further layers of risk. Complying with recognised safety standards and using layered protection reduces incidents, protects your workforce, and keeps machines running, minimising costly downtime and liability.

Best Laser cutting services by Cyclotron Industries. We offer high precision, fast and accurate laser cutting solutions for any kind of metal applications

Common Hazards in Laser Cutting Operations

You need to be careful about the following risks in laser cutting operations:

- Laser Beam Exposure:

The direct or reflected laser beams can cause painful burns and permanent eye damage. Even short exposures to focused light can injure the retina. Reflections from shiny or reflective surfaces are a common source of accidental exposure; always treat them with extra caution. - Fire & Heat Hazards:

The hot work is an inherent part of laser cutting. Sparks, molten metal, and hot slag can ignite flammable materials or cause burns. A small scrap left on the table or an oily rag nearby is enough to start a serious fire. - Fumes, Smoke & Dust:

Cutting the stainless steel, aluminium, galvanized steel, or painted/coated parts produces the fumes that may contain metal oxides and other harmful compounds. Without proper extraction and filtration, these particulates accumulate and impact respiratory health. - Mechanical Risks: Moving gantries, sheet loaders, and automated handling introduce the pinch points, crush hazards, and strike risks. Sharp sheet edges and heavy plates increase the chance of cuts and musculoskeletal strains if not handled correctly.

- Electrical & Machine Control Risks:

Industrial lasers use high-voltage components and complex CNC controls. Faulty wiring, damaged cables, or improper grounding raise the risk of electric shock or unexpected machine movements.

Essential Safety Measures for Laser Cutting Operations

Safety measures in laser cutting operations must be layered: engineering controls, administrative controls, and personal protective equipment (PPE). Below are practical actions to put these layers in place.

Use of Personal Protective Equipment (PPE)

- Laser cutting safety goggles matched to the laser wavelength and optical density.

- Heat-resistant gloves for handling hot parts and slag.

- Safety shoes with steel toes for heavy-sheet handling.

- Protective clothing (long sleeves, no synthetic materials that melt) to guard against sparks.

Proper Machine Guarding & Enclosures

Enclosed cutting systems with interlocks prevent accidental exposure of beams. Windows should be fitted with laser-rated viewing panels and interlocks that deactivate the beam when doors open. Never bypass safety interlocks or use machines with disabled guards.

Ventilation & Fume Extraction

Locate the extraction hoods near the cut zone and use the proper filters for metal particulates and fumes. Regularly inspect the ducting and filtration systems, and ensure extraction rates are sufficient for the material and process. Consider local capture plus central filtration for high-volume shops.

Material Handling Safety

Use mechanical lifters, vacuum lifters, or sheet loaders for heavy plates. Apply the safe lifting techniques for manual handling, and wear anti-cut gloves to protect from sharp edges. Secure the loose parts before cutting and use proper storage racks to prevent tipping.

Fire Prevention Measures

Keep the fire extinguishers rated for metal and electrical fires within easy reach. Maintain a clear zone around the machine free of flammable materials. Clean slag trays and cutting tables frequently to prevent the accumulation of combustible waste.

Electrical Safety Practices

Implement lockout/tagout procedures during maintenance and repairs. Schedule the periodic inspections of cables, connectors, and grounding points. Only qualified electricians should service high-voltage components and test grounding systems.

Emergency Stop Systems

E-stop buttons should be visible, easily accessible, and tested daily. Train operators on emergency shutdown procedures and run periodic drills so everyone knows how to respond quickly and safely.

Operator Training & Skill Requirements

The operators must be trained not only in machine operation but in safety culture.

Training topics should include machine controls, parameter selection, hazard recognition, emergency response, and routine checks. Make sure the operators understand laser classes and why certain protective measures are mandatory.

Only authorised, trained personnel should have access to the control area, and refresher training must be scheduled regularly.

Safety Standards & Compliance

You need to follow recognised standards such as ISO 11553 for laser cutting safety and relevant local regulations. CE-marked machines indicate conformity with EU directives, but you must also comply with national occupational safety regulations and site-specific policies. Use standards as the backbone of your formal safety program and keep documentation for audits.

Best Practices for a Safe Laser Cutting Environment

- Keep walkways clear and floor markings visible.

- Ensure good lighting to spot hazards and read control panels.

- Store metal sheets upright and secure to prevent tipping.

- Use digital monitoring and alerts to track the machine health and process status.

- Restrict machine access to trained staff only; consider badge access or gating for high-risk areas.

Common Mistakes That Lead to Accidents

- Using the wrong or no PPE.

- Cutting unknown or highly reflective materials without verification.

- Ignoring warnings, alarms, or machine maintenance prompts.

- Operating equipment with damaged guards or bypassed interlocks.

- Overloading the table or incorrect sheet positioning that leads to jams or unexpected movements.

Safety Checklist for Laser Cutting Operators

Here is a Quick daily checklist for safety measures in laser cutting operations:

- PPE is correctly worn and in good condition.

- Machine guard and enclosure intact.

- Fume extraction is on and functioning.

- Correct CNC program loaded and verified.

- Work area tidy, no loose combustible material.

- E-stop tested and accessible.

- Fire extinguisher present and inspected.

FAQs

- What PPE is required for laser cutting?

Use laser-rated eyewear for the specific wavelength, heat-resistant gloves, safety shoes, and protective clothing. PPE choice depends on the material and cutting process. - How do you prevent fire during laser cutting?

You need to keep the work area clean, use appropriate cutting parameters, ensure proper extraction, and have suitable extinguishers nearby. Remove combustible materials from the cutting zone and inspect the table regularly. - How often should laser cutting machines be inspected?

Daily visual checks by operators, scheduled preventive maintenance weekly or monthly depending on usage, and annual safety audits. Follow manufacturer recommendations and adjust frequency based on workload.

Best Laser cutting services by Cyclotron Industries. We offer high precision, fast and accurate laser cutting solutions for any kind of metal applications

Conclusion

Safe laser cutting operations combine thoughtful engineering, strict administrative controls, regular maintenance, and well-trained operators. By applying these safety measures in laser cutting operations, fabrication teams reduce risks of injury, prevent costly incidents, and create a reliable production environment. A safer shop-floor is more productive, profitable, and respected by all.

Best Laser cutting services by Cyclotron Industries. We offer high precision, fast and accurate laser cutting solutions for any kind of metal applications

Laser cutting services

Laser cutting services in Pune

Fiber laser cutting services in Pune

Metal laser cutting services in Pune

Laser cutting for sheet metal parts

CNC Laser cutting services in Pune