Laser cutting job work in Pune

Laser cutting job work in Pune

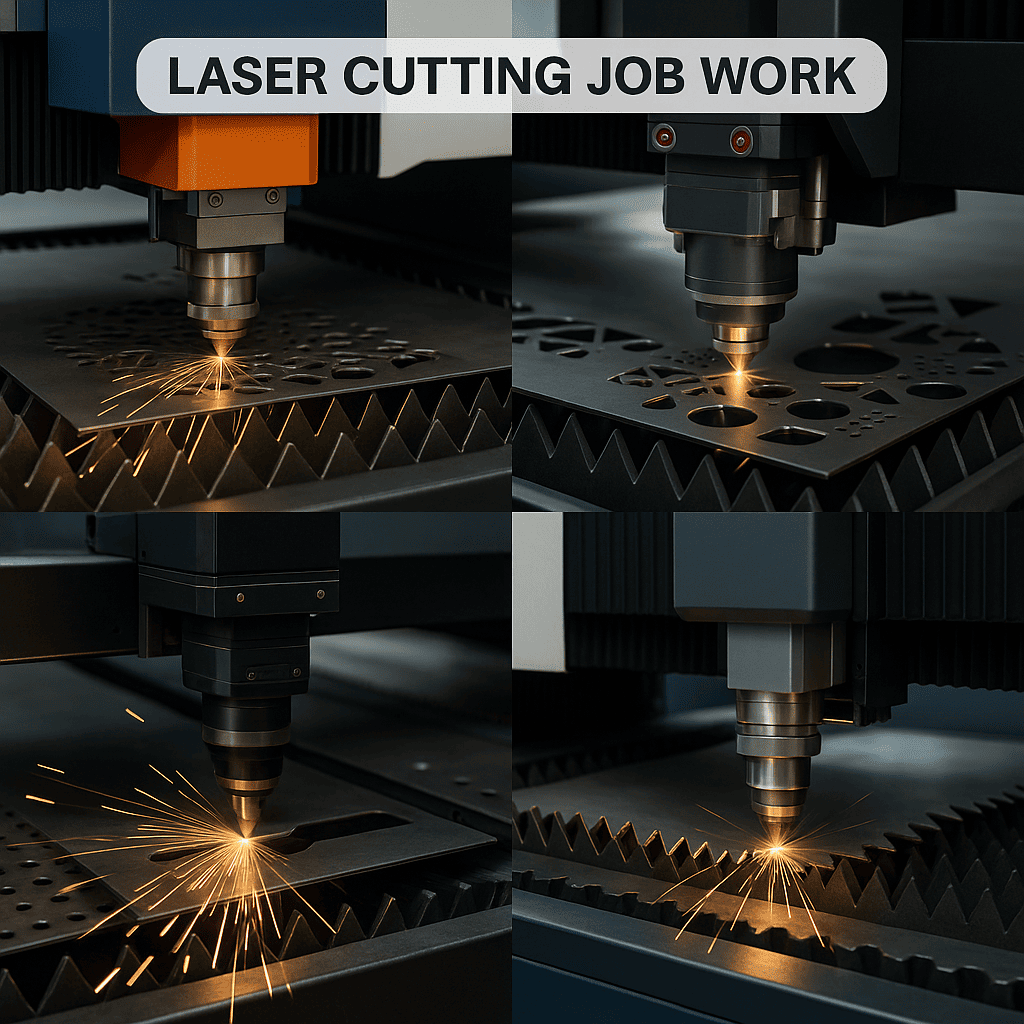

We understand that precision isn’t optional; it’s the foundation of every part, product, and structure you build. Cyclotron Industries, located in Pune, our laser cutting job work combines advanced fiber-laser technology.

Our professionals possess hands-on expertise in delivering clean edges, tight tolerances, and consistent repeatability across materials such as mild steel, stainless steel, and aluminium.

- Whether you need a single prototype or thousands of production parts, we tailor our process to your project’s specific goals: reducing waste, speeding delivery, and cutting costs. This post outlines our comprehensive end-to-end services, from CAD validation to finishing, and explains why manufacturers, fabricators, designers, and exporters in Pune choose us for dependable, cost-effective laser cutting.

Read on for specific capabilities, materials, and thickness ranges, as well as the industries we serve, our pricing philosophy, and a straightforward four-step workflow to ensure your parts are manufactured correctly the first time. We take pride in our clear communication and on-time delivery. Trusted by national customers regularly.

Best Laser cutting services by Cyclotron Industries. We offer high precision, fast and accurate laser cutting solutions for any kind of metal applications

Professional Laser Cutting Job Work Services

- Cyclotron Industries offers comprehensive end-to-end laser cutting job work in Pune, encompassing every stage from CAD drawing validation to cutting, inspection, and dispatch. Our process is designed for precision at scale, ensuring that each job meets its tolerance, finish, and delivery commitments with accuracy.

- We understand that every customer’s requirement is unique. Whether it’s a prototype for validation or a recurring production batch, we maintain the same level of care and quality control throughout.

- Our services include: Sheet metal laser cutting (MS, SS, Aluminum), Custom part cutting as per DXF/DWG files, Prototype and bulk production jobs, Cutting for fabrication assemblies and OEM components, Precision job work for export or local use.

Choosing the right partner for laser cutting isn’t just about getting a part cut. It’s about providing a consistency, on-time delivery, and dependable quality. At Cyclotron Industries, we’ve built our reputation on these principles.

Our setup combines the state-of-the-art fiber laser systems with experienced operators and digital process monitoring. This synergy allows us to maintain precision on every batch, whether it’s a small custom order or a large industrial lot.

- Advanced Fiber Laser Technology: Our facility is equipped with high-power fiber laser machines capable of cutting up to 25 mm in mild steel and 20 mm in stainless steel. The technology provides clean, burr-free edges, minimal heat distortion, and high repeat accuracy. These systems handle intricate geometries and tight curves with ease, making them ideal for parts requiring complex contours or decorative designs.

- Accuracy and Repeatability: Consistency is the heart of every successful production line. Each part we cut is verified against CAD data and dimensional standards. The laser’s positional accuracy of ±0.1 mm ensures every repeat order matches perfectly with previous runs. Our customers rely on this repeatability to streamline assembly processes, minimize fitting adjustments, and ensure product interchangeability.

- Fast Turnaround: Speed without compromising accuracy, that’s our promise. With optimized nesting software and 24/7 operational capability, Cyclotron Industries provides faster lead times even for complex jobs. We understand that fabrication schedules are tight, so we plan our workflow to efficiently meet urgent or high-volume requirements.

- Transparent Pricing: We follow a transparent and fair pricing structure based on cutting length (per mm or per meter) and material thickness. Bulk orders receive volume-based cost benefits without any compromise on quality. Our team provides detailed quotations that outline the material utilization and cutting parameters, helping clients understand the value they receive for every project.

- One-Stop Fabrication Support: Laser cutting is often the first step in a larger fabrication workflow. That’s why we also provide post-cutting support under one roof, including bending, welding, surface finishing, and sub-assembly. This type of integrated approach helps clients save time and coordination effort, reducing logistics between multiple vendors.

- The result: faster project completion and greater control over quality.

| Material | Cutting Thickness Range | Application |

|---|---|---|

| Mild Steel (MS) | 0.5 mm – 25 mm | Structural, general fabrication |

| Stainless Steel (SS) | 0.5 mm – 20 mm | Pharma, food, decorative panels |

| Aluminum | 0.8 mm – 12 mm | Enclosures, machine covers |

| Copper / Brass | 0.8 mm – 5 mm | Electrical and decorative |

| Acrylic / Non-Metals | Up to 10 mm | Signage and design work |

Best Laser cutting services by Cyclotron Industries. We offer high precision, fast and accurate laser cutting solutions for any kind of metal applications

Industries We Serve

Pune’s manufacturing ecosystem thrives on precision and productivity. We are proud to serve multiple sectors that depend on accurate and timely laser cutting in Pune.

Key industries include:

- Automotive components and fixtures – Brackets, gussets, and tooling plates

- Heavy fabrication and machinery – Base frames, support plates, guards

- Electrical panels and enclosures – Control panels, cabinet doors, busbar supports

- Furniture and interior design –

- Decorative panels, signage, customized patterns

- Industrial equipment and OEM parts –

- Machine covers, housings, sub-assemblies

Our clients operate across Chakan, Bhosari, Pimpri-Chinchwad, Talegaon, and other major industrial areas of Pune.

Whether it’s a local fabrication unit or an export-oriented manufacturer, we ensure each project receives the same precision and attention to detail.

How to Get Laser Cutting Job Work Done

Getting your laser cutting job work completed with Cyclotron Industries is a transparent and straightforward process. We follow a four-step process designed for speed, clarity, and accountability.

- Send Your Design – Firstly, share your DXF, DWG, or PDF drawings along with material and quantity details.

- Get a Quote – Secondly, our team reviews your file, optimizes nesting, and provides a detailed quotation with delivery timelines.

- Cutting & Inspection – Once confirmed, we execute the precision cutting, followed by dimensional and visual inspection.

- Delivery – Finished parts are dispatched within the committed schedule, safely packed, and ready for fabrication or assembly.

This process ensures that you receive accurate components, transparency in costs, and on-time delivery every time.

Frequently Asked Questions

Q: What file formats do you accept?

A: DXF, DWG, and PDF files with clear dimensions.

Q: Can you cut unusual materials?

A: We cut a wide range of metals and some non-metals; check with our team for specifics.

Q: Do you offer finishing services?

A: Yes deburring, grinding, bending, welding, and surface finishes are available.

Q: How do you price jobs?

A: Pricing is based on material, thickness, complexity, quantity, and any secondary processes.

Best Laser cutting services by Cyclotron Industries. We offer high precision, fast and accurate laser cutting solutions for any kind of metal applications

Laser cutting services

Laser cutting services in Pune

Fiber laser cutting services in Pune

Metal laser cutting services in Pune

Laser cutting for sheet metal parts

CNC Laser cutting services in Pune