Laser cutting for Defence components

Laser cutting for Defence components

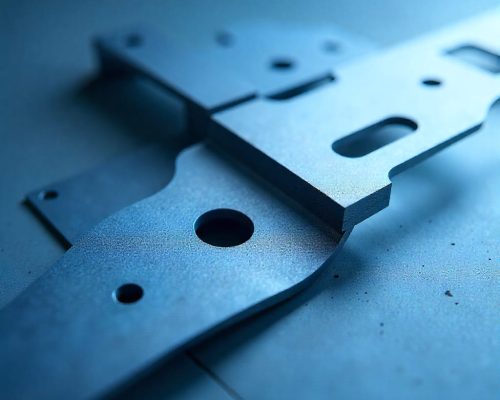

Equipment manufacturing in the defence industry demands high precision, efficiency, and versatility. With its unique capabilities, Laser cutting has proven to be a technological marvel in the military, aerospace, and defence sectors.

This innovative technology has the potential to easily handle a range of manufacturing projects, from simple to complex, while adhering to MIL-spec and quality requirements. Want to know why the defence sector heavily relies on this state-of-the-art technology and what sets laser cutting of defence parts apart? Let’s explore the numerous benefits that fibre laser cutting for defence parts offers in this high-stakes sector.

With high power density and optimal material utilization, CNC-controlled laser cutting services for defense parts offer unmatched precision. It is a cost-effective solution for the manufacturing of defense equipment, such as turbine blades, airframe components, and electronic enclosures, with extremely tight tolerances.

- Fibre Laser can cut through all types of metals, from carbon steel to titanium, aluminium, brass, and copper, with speed and ease. Undeniably, cutting defense parts has become a go-to process for a range of machining, manufacturing, and prototyping projects. This comprehensive guide examines the role of laser cutting in the defense industry, its applications, and the numerous benefits it provides in this critical sector.

Importance of Precision in Defence Parts

- Precision is the primary factor in the manufacturing and cutting of defence parts. From military trucks and aircraft to water-based operations, there is no margin for human error or defects in mission-critical equipment. The major reason why the defence industry relies on laser cutting is the on-time delivery, precision, and ability to meet stringent military specifications (MIL-SPEC) & quality requirements.

- Laser-cut metal components are highly durable, efficient, and can perform under extreme conditions. In addition, laser cutting for defence equipment can craft highly durable metal components with strict tolerances using a wide array of metals

- This cost-effective yet optimal solution offers minimal waste, faster turnaround times, and lower downtimes as compared to traditional cutting techniques.

Military and defence equipment requires a high degree of precision, quality, and efficiency to avoid any susceptibility to duplication. The military grade equipment & components produced by laser cutting technology stand out as a robust solution. Unlike conventional cutting, laser cutting services for defence parts offer micro-level precision and defect reduction in numerous defence applications. Here are some unique characteristics of laser cutting for defence parts:

- High-precision cutting of defence parts (metals & alloys)

- Rapid prototyping of defence components such as brackets & armoured vehicle panels.

- Mass volume production of complex geometries for weapons, armoured vehicles, and ground systems.

Apart from the ability to cut hard and exotic alloys that meet the strict MIL-SPEC & requirements, laser cutting for defence equipment offers numerous advantages. Take a look!

High accuracy & repeatability

Fiber laser cutting is recognised for its unmatched precision & accuracy. Based on the CNC system, a high-powered fiber laser allows the repeated mass production of military components.

Faster turnaround

Laser cutting for defence parts offers faster speed & turnarounds as compared to traditional methods.

Minimal material waste: The laser beam generated hits the small spot on the metal sheet, ensuring burr-free edges, high-quality cutting of defense parts, and low material warping.

Clean finishes: Most often, the final equipment or component created using laser cutting for defence equipment doesn’t require secondary processes like anodising or heat treatments.

Laser cutting for Defence components by Cyclotron Industries. We offer high precision, fast and accurate laser cutting solutions for any kind of metal applications

Materials Used in Defence Laser Cutting

Lasers can effectively cut through a range of metals depending on their properties. Below is the list of the most compatible metals used for cutting of defence parts in this industry.

1.Stainless steel & hardened steel

Fibre laser cutting is highly effective on steel grades (such as 303 & 17-4 ph) due to its durability and corrosion resistance.

2. Aluminium alloys

Lightweight metals like 6061 offer high strength, making them an excellent choice for crafting engine parts, electronic enclosures, and chassis, among other applications, in the defense industry.

3. Titanium alloys

With features such as a high strength-to-weight ratio, titanium alloys like Inconel are widely used in the manufacturing of turbine blades and other high-performance components for aircraft.

4. Nickel-based alloys

Fiber lasers can easily cut through nickel-based alloy metals (high-temperature strength) while providing burr-free edges and quality cuts.

Conventional cutting methods like sawing, plasma, and milling are ideal for cutting thick metals. But when it comes to the modern defence sector, which demands precision, rapid manufacturing of mission-critical components, laser cutting is the undisputed champion. Here are some key differences:

| Features | Laser Cutting for Defence Equipment | Conventional Cutting |

|---|---|---|

| Speed & Efficiency | CNC-controlled mechanism offers fast & repeated production of complex metal parts. | Physical contact limits speed & increases heat production, resulting in material warping. |

| Precision & Defects | Extremely tight tolerances (as low as ±0.001 inches) with minimal material wastage & zero defects. | Due to mechanical tools & stress, dimensional inaccuracies and geometric errors are common. |

| Cost-Effectiveness | High set-up cost with almost no operational & maintenance cost. | Low installation cost but requires high maintenance costs. |

| Value in High-Security Applications | High value in the defence industry due to precision, speed & versatility. | Lesser value, more susceptible to duplication or quality inconsistencies. |

With years of experience and expertise in defense-grade alloys, Cyclotron utilizes advanced CNC fiber laser technology in Its Laser Cutting services for defense parts. With proven precision engineering capabilities spanning prototyping through to full-scale production, we promise to deliver the highest-quality defense equipment and metal components on time. Here’s why us?

Unmatched precision & versatility

Competitive prices

Integration with advanced technology

Multi-material cutting services

Rapid prototyping & production

Dedicated customer support

Can laser cutting handle thick armour-grade steel?

Cutting of defence parts depends on the required quality, thickness, and properties of the metal. Armour steel is quite hard and requires heat treatment. Laser cutting for defence equipment may lead to microcracks and a high HAZ (heat-affected zone).

How reliable is laser cutting for defence applications?

With its exceptional versatility, precision, and tight tolerances, laser cutting benefits the defence sector with multiple applications. It includes the fabrication of armoured vehicles, aircraft components, sensor systems, etc.

What standards must be followed in the defence part manufacturing?

While manufacturing, assembling or cutting of defence parts, the industries must adhere to the following three global standards:

- QMS (Quality management system)

- MIL-SPEC

- Regulatory & security standards such as ITAR, CMMC.

Laser cutting for Defence components by Cyclotron Industries. We offer high precision, fast and accurate laser cutting solutions for any kind of metal applications

Laser cutting services

Laser cutting services in Pune

Fiber laser cutting services in Pune

Metal laser cutting services in Pune

Laser cutting for sheet metal parts

CNC Laser cutting services in Pune