Laser cutting design guidelines for sheet metal

Laser cutting design guidelines for sheet metal

Laser cutting design guidelines for sheet metal depends on various factors like material, material thickness, kerf, heat affected zone, etc

- Designing sheet metal parts with precision is not just about cutting the shapes. It is about providing accuracy, quality, and cost efficiency at every stage.

- Following the proper laser cutting design guidelines for sheet metal helps the manufacturers avoid errors, reduce waste, and achieve consistent results across production runs. When designs are optimized for laser cutting, parts fit better, assembly becomes smoother, and finishing work is minimized. This means faster turnaround times and lowers the overall costs.

- By applying the right laser cutting design guidelines, engineers and designers can make smarter choices about material thickness, tolerances, hole sizes, and edge quality. These small details add up to big advantages in performance and durability. Whether you are creating prototypes or large-scale production parts, clear design rules ensure that the process remains efficient and reliable.

- In short, good design is the foundation of successful sheet metal laser cutting projects.

- This blog post provides a brief overview of the essential information you need to know about laser cutting design guidelines for sheet metal.

Best Laser cutting services by Cyclotron Industries. We offer high precision, fast and accurate laser cutting solutions for any kind of metal applications

Basics of Sheet Metal Laser Cutting

Laser cutting uses a focused beam to melt, vaporize, or ablate material along a programmed path. Modern shops typically use fiber lasers for steel and stainless steel, and sometimes the CO₂ or other systems, depending on the material. Essential basics to remember:

- Material behaviour:

Mild steel, stainless steel, and aluminium respond differently to heat. Aluminium reflects light and conducts heat quickly, which affects the precision. - Thickness limits:

Most shops cut thin sheets very precisely and can cut up to thicker plates; however, precision and edge finish degrade as the thickness increases. - Kerf:

The kerf is the width of material removed by the laser. Typical kerf ranges from about 0.05 mm for very fine work up to 0.5 mm or more on thicker cuts. Always measure your supplier’s kerf. - Heat-Affected Zone (HAZ):

A narrow band beside the cut that changes the color and material properties. Minimize hazards by operating at correct speeds and avoiding excessive dwell times

Best Laser cutting services by Cyclotron Industries. We offer high precision, fast and accurate laser cutting solutions for any kind of metal applications

Core Laser Cutting Design Guidelines

These are the practical rules you can apply in computer aided Laser Cutting Design Guidelines today.

1. Minimum Hole & Slot Size

- Hole diameter rule: As a baseline, make the hole diameter at least equal to the material thickness. For example, use holes with a diameter of≥ 2 mm for a 2 mm sheet.

- Slots: Keep slot width greater than the kerf —a safe starting point is 1.5× the measured kerf. Long, narrow slots are prone to distortion; if you need very narrow slots, consider redesigning to a punched feature or using specialized cutting parameters.

- Tiny features: Holes significantly smaller than the sheet thickness will likely distort or melt closed. Redesign if you need very small internal features.

2. Minimum Web / Bridge Thickness

- Keep internal webs or bridges at least equal to the material thickness (1×) and preferably 1–1.5× thickness for stability. Very thin webs burn away or warp during cutting and handling.

3. Corner Radius Recommendations

- Avoid perfectly sharp internal corners. Use a radius of about 0.5× the sheet thickness for internal corners — this helps maintain consistent kerf and reduces stress concentrations that cause cracking during forming

4. Distance Between Features

- Heat buildup and thermal distortion increase when features are close. Use edge-to-edge spacing ≥ 1× thickness for thinner sheets and increase spacing for thicker materials. Critical or tiny parts should have extra clearance.

5. Kerf Allowance:

- When parts must fit together precisely, add kerf compensation to provide a tight fit. Model mating edges with half the kerf subtracted from one part and half added to the other or talk to your laser shop to agree on a fit tolerance.

6. Lead-Ins & Lead-Outs:

- Use small lead-ins or micro-joints to prevent pierce marks and keep small internal pieces attached until they are cleaned. Place lead-ins on non-visible faces or inside bend sections where they won’t be seen.

Tolerances & Material Considerations

When designing the sheet metal parts for laser cutting, tolerances (the acceptable variation in dimensions) depend heavily on the type of material and its thickness.

- Mild Steel (MS)

For the thin sheets (≤3 mm), expect an accuracy of around ±0.1 mm; thicker sheets may require an accuracy of ±0.2–0.3 mm. - Stainless Steel (SS)

The accuracy of stainless steel is comparable to that of mild steel. However, stainless steel is more prone to warping when exposed to high temperatures during the cutting process. Designers should account for this by avoiding overly tight tolerances in critical areas. - Aluminium

Less predictable due to reflectivity and thermal conductivity — allow ±0.15–0.3 mm depending on thickness.

If fit or alignment is critical, plan for test cuts and iterate with your fabricator to ensure the optimal results.

Bending & Forming Notes

- Bend relief: Small notches or cutouts at internal corners where the bend will cause material to pinch — prevents tearing.

- Bend line clearance: Keep the holes and cutouts 2–3× material thickness away from the bend centerline to avoid distortion.

- Grain direction: For some materials, orient the grain with the bend to reduce cracking and unpredictable springback.

Nesting & Layout Tips

Smart nesting reduces the cost:

- Keep parts spaced: Allow consistent gaps (typically 1–3 mm) depending on thickness to account for kerf and thermal spread.

- Avoid overlapping lines: Duplicate cuts waste time and create burrs.

- Use common-line cutting: When two parts share an edge, common-line cutting removes duplicate kerf and shortens cycle time — ideal for panels and straight edges.

Common Design Mistakes to Avoid

Designing for fabrication requires foresight; overlooking small details can cause costly errors. Avoid these frequent mistakes to provide manufacturable, durable, and reliable parts that meet performance and production standards.

- Designing very small internal features that the laser can’t reliably cut:

Laser cutters have a minimum kerf (cut width). If you design tiny slots, holes, or intricate details smaller than that, the laser either won’t cut them cleanly or they’ll burn away.

Example: A 0.5 mm hole in 3 mm steel is usually impossible — the hole will close up or distort. - Using too-thin walls or bridges that burn away:

Thin connections between parts (like tabs or bridges) can overheat and vaporize during cutting.

This can weaken the structure and may cause parts to break off unintentionally.

Rule of thumb: Keep walls at least 1–2× the material thickness. - Forgetting bend reliefs on parts that will be formed

When bending sheet metal, stress concentrates at corners. Without relief cuts, the material can tear or deform.

Bend reliefs are small notches or slots that prevent cracking and provide clean bends.

Placing critical holes too close to bends

Holes near bend lines distort when the sheet is formed, making them unusable for fasteners or alignment.

Best practice: Place holes at least 2× the material thickness away from the bend line.

Best Laser cutting services by Cyclotron Industries. We offer high precision, fast and accurate laser cutting solutions for any kind of metal applications

Summary Checklist for Designers

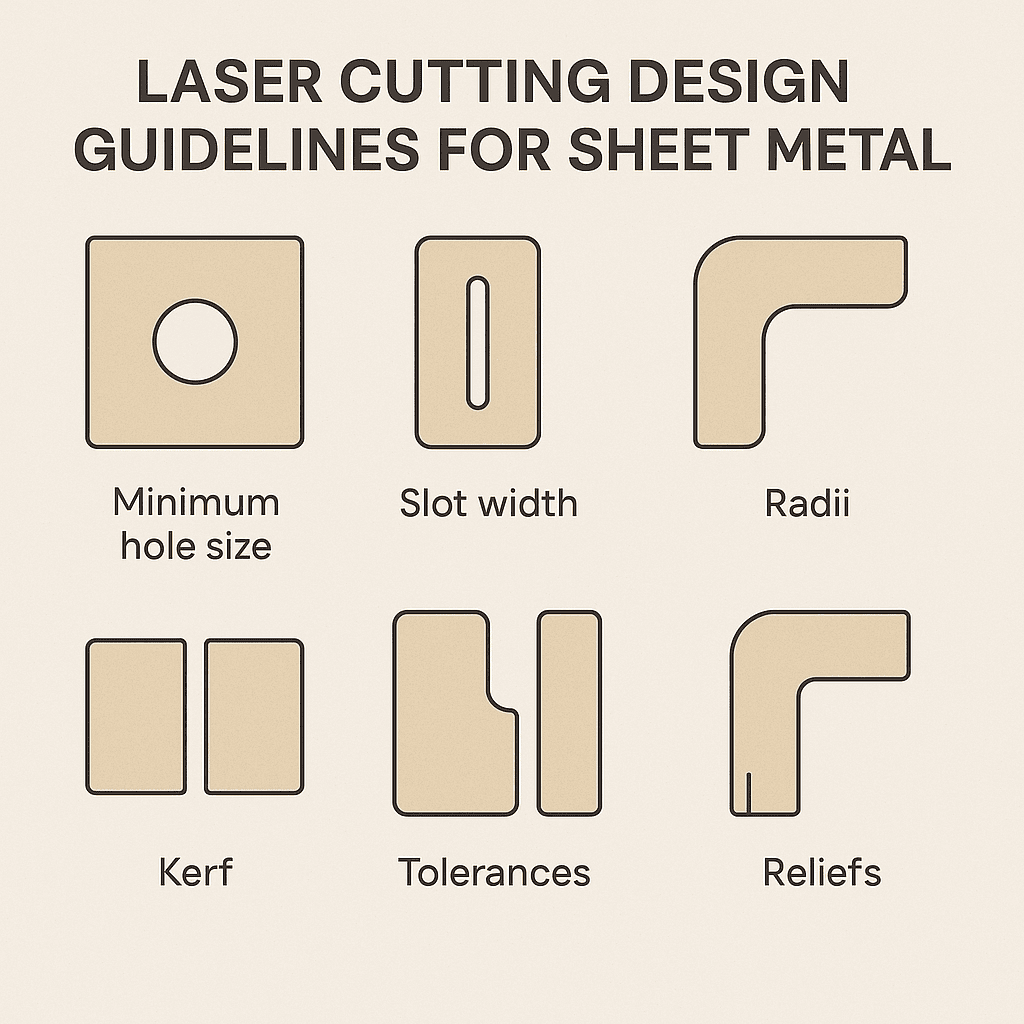

When working on laser cutting design guidelines for sheet metal, it helps to keep a quick, handy checklist. Think of this as your “at‑a‑glance” reminder to avoid common pitfalls and make sure your parts are both manufacturable and durable.

- Minimum hole size → Ensure the holes are not smaller than the laser’s kerf; too tiny and they’ll close up.

- Slot width → Keep slots wide enough to cut cleanly; narrow slots risk burning away or warping.

- Radii → Add corner radii to reduce the stress and prevent cracking during bends.

- Kerf → Account for the laser’s cutting width in your design so parts fit together properly.

- Tolerances → Allow realistic clearance; sheet metal thickness and cutting precision vary slightly.

- Reliefs → Add bend reliefs near corners to avoid tearing when the sheet is formed.

Laser cutting services

Laser cutting services in Pune

Fiber laser cutting services in Pune

Metal laser cutting services in Pune

Laser cutting for sheet metal parts

CNC Laser cutting services in Pune