Industrial laser cutting services in Pune

Industrial laser cutting services in Pune

As industries aim for shorter production cycles, tighter tolerances, and higher product quality, the demand for precise and efficient cutting solutions increases. Industrial laser cutting services have evolved into a modern industrial staple, offering unparalleled accuracy, speed, and consistency for large-scale production.

- Laser cutting, like as traditional cutting technologies, provides clean edges, minimum waste, and repeatable precision, making it an excellent choice for sectors that value quality and productivity. Laser technology is rapidly being adopted by businesses to stay competitive in the modern, demanding industrial landscape, spanning automotive and heavy engineering, construction, and specialized fabrication.

This blog post provides a brief overview of everything you need to know about industrial laser cutting, including its applications and more.

Best Laser cutting services by Cyclotron Industries. We offer high precision, fast and accurate laser cutting solutions for any kind of metal applications

What Are Industrial Laser Cutting Services?

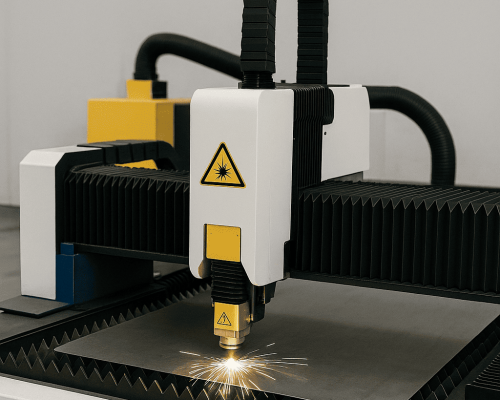

- Industrial laser cutting uses high-power fiber or CO₂ lasers to cut metal sheets and components. CNC-controlled systems guide the laser for accurate shapes and clean edges.

- This method provides consistent quality, faster production, and superior finishes. It is widely used in large-scale production where precision is key.

Why Choose Industrial Laser Cutting?

Laser cutting is widely used in industrial settings due to its accuracy, speed, and automation capabilities. It reduces material waste and is ideal for medium to high-volume production. Here are some main reasons industries prefer it:

- Consistent Quality at Scale: Industrial laser cutting gives the same accurate cut every time. Once a part’s program is set up, the machine repeats the same motion for hundreds or thousands of pieces. That means fewer mistakes, less rework, and predictable parts that fit together straight away. For businesses, this reliability saves time and ensures that customer orders are fulfilled on schedule without any surprises.

- Faster Production Speeds: High-power lasers move quickly and can cut complex shapes much faster than many manual or mechanical methods. Because the beam is so focused, the machine needs fewer passes and less handling. Faster cutting reduces lead times, enabling you to receive parts more quickly. For tight deadlines or large batches, laser cutting allows factories to complete jobs more efficiently and ship products on time.

- Cost-Effective for Bulk Jobs: When you run many parts, small savings add up. Nesting software groups parts tightly to use more of each sheet, and the laser follows optimized paths to cut with minimal wasted motion. Fewer scrap and fewer manual steps reduce material and labor costs. Over many cycles, these efficiencies make laser cutting a cheaper option per part for medium and large production runs.

Applications of Industrial Laser Cutting

Industrial laser cutting is widely used in various industries due to its ability to deliver accuracy, speed, and clean finishing. Below are the main applications explained in simple points

1. Automotive Industry: In the automotive sector, laser cutting is used to make components such as brackets, exhaust systems, and chassis frames. The process provides that every part fits perfectly, reducing assembly errors and rework. It also helps manufacturers produce lightweight yet strong components that improve vehicle performance and safety. Laser cutting is ideal for both prototype and mass production.

2. Heavy Machinery: Laser cutting plays a crucial role in the production of heavy machinery. It produces strong and durable components, including base frames, panels, and machine supports. The precision offered by laser technology ensures that each part is accurately shaped, enhancing the overall performance of the machine. Additionally, it minimizes the need for manual finishing, thereby saving both time and effort in large-scale production.

3. Construction Industry: In the construction industry, laser cutting plays a key role in shaping metal sheets, beams, and structural elements used in buildings and infrastructure. It helps builders achieve perfect alignment and fitting of parts, resulting in stronger and more reliable structures. The clean cuts and quick turnaround also make it suitable for modern architectural designs.

4. Défence Sector: The defence industry relies on laser cutting for making parts that require extreme precision and durability. Components used in vehicles, weapons, and protective systems are laser-cut to provide high quality and reliability under harsh conditions. This vast technology enables the rapid production of complex designs while maintaining strict accuracy and safety standards.

5. Infrastructure Projects: Laser cutting plays a crucial role in large-scale infrastructure projects, including bridges, railways, and pipelines. It produces precisely cut metal parts that fit perfectly during installation, providing structural integrity and long-term reliability. Additionally, the process enables the customization of parts to meet specific project requirements, helping engineers save time and minimize material waste.

Materials and Thickness Range

Industrial laser cutting is compatible with a wide range of metals, offering manufacturers the flexibility to handle both small and large projects. It allows precise cutting on both light sheets and heavy fabrication materials.

- Mild Steel (MS) – Up to 40 mm

Mild steel is widely used in industrial projects because it is strong yet easy to shape. Laser cutting can handle sheets up to 25 mm thick, producing clean edges and smooth surfaces. It is ideal for frames, panels, brackets, and structural components where strength matters. - Stainless Steel (SS) – Up to 25 mm

Stainless steel is valued for its corrosion resistance and durability.

Laser cutting up to 20 mm thick enables the creation of accurate and consistent shapes for machinery, kitchen equipment, and architectural projects. The process minimizes heat-affected zones, keeping the metal strong and ensuring smooth finished edges. - Aluminium – Up to 16 mm

Aluminium is lightweight and easy to work with, and it is often used in automotive, aerospace, and construction industries. Laser cutting up to 12 mm thick creates precise components without bending or warping. This makes it perfect for panels, enclosures, and decorative or structural elements. - Copper/Brass – Up to 10 mm

Copper and brass are softer metals but require careful cutting due to high reflectivity. Laser cutting up to 5 mm thick ensures smooth edges and precise shapes for electrical components, plumbing fixtures, and decorative items. This allows manufacturers to maintain the quality while reducing material waste.

Best Laser cutting services by Cyclotron Industries. We offer high precision, fast and accurate laser cutting solutions for any kind of metal applications

Industrial Laser Cutting Services in India

- Laser cutting has become a vital component of modern manufacturing in India.

- With the rise of advanced fiber laser systems, industries can now achieve high precision, faster production, and cost-effective fabrication.

- Throughout the country, several cities have emerged as strong hubs for these services. Pune, Chennai, Ahmedabad, and Faridabad are the leading cities that have reliable and professional industrial laser cutting companies.

- In short, India’s manufacturing sector is embracing laser technology to stay competitive, provided that companies can rely on efficient and accurate cutting services for their projects.

Advantages of Partnering with Cyclotron for Industrial Laser Cutting

Cyclotron offers a complete Industrial laser cutting services in Pune, combining advanced technology with skilled expertise to deliver precision and efficiency. Here is why you should choose Cyclotron:

- High-Power Fiber Laser Machines (up to 10kW):

These types of machines can cut through thick metals and complex geometries with exceptional speed and accuracy. The high wattage provides clean edges, minimal material waste, and the ability to handle demanding industrial applications. - Trained Operators and Engineers:

Our Skilled professionals oversee every stage of production, from machine setup to quality checks. Our expertise reduces errors, optimizes cutting parameters, and ensures that projects meet the exact specifications. - Digital Production Tracking & Inspection Reports:

Cyclotron integrates the digital monitoring tools that provide real-time updates on project progress. Inspection reports can provide transparency and quality assurance, providing clients with confidence that standards are consistently met. - Fast Turnaround for Bulk & Urgent Orders:

With the streamlined workflows and powerful equipment, Cyclotron can handle large-scale production runs while still accommodating urgent requests. This flexibility enables businesses to meet tight deadlines without compromising quality. - Integration with Bending, Welding & Finishing Processes:

Beyond cutting, Cyclotron offers complete Industrial laser cutting services in Pune like bending, welding, and finishing. This end-to-end integration reduces the need for multiple vendors, shortens lead times, and ensures seamless coordination across all stages of the manufacturing process.

Best Laser cutting services by Cyclotron Industries. We offer high precision, fast and accurate laser cutting solutions for any kind of metal applications

Laser cutting services

Laser cutting services in Pune

Fiber laser cutting services in Pune

Metal laser cutting services in Pune

Laser cutting for sheet metal parts

CNC Laser cutting services in Pune