High precision laser cutting services

High precision laser cutting services

Cyclotron industries is the leader in high precision laser cutting services for industries with very high accuracy requirements. Precision laser cutting in Pune, India

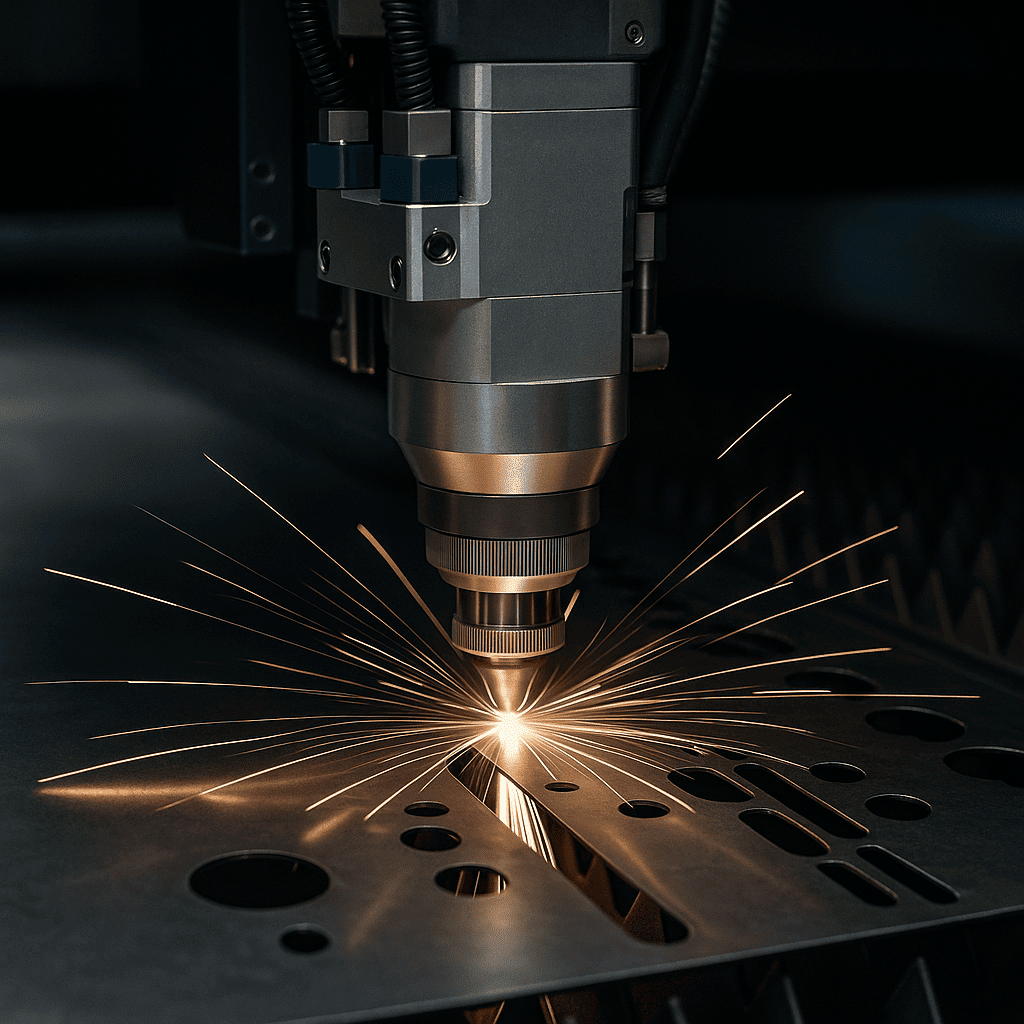

Every cut tells a story of precision. In industries where the margin for error is smaller than the width of a human hair, high-precision laser cutting has become an essential manufacturing tool.

By combining fiber laser technology with high-speed motion systems, this process achieves micron-level tolerances and exceptionally clean edges across complex geometries. Unlike conventional cutting, it eliminates the mechanical stress, reduces rework, and provides dimensional consistency in every component

From stainless steel surgical parts to intricate electronic housings, high-precision laser cutting supports a diverse range of sectors that rely on accuracy and reliability. As global standards tighten and product expectations rise, this technology continues to redefine how perfection is produced one laser pulse at a time.

This blog post provides a brief overview of high-precision laser cutting services. It covers the benefits of this technique, the materials typically used, and the key features that define high-precision laser cutting. It also explores many other crucial aspects of high-precision laser cutting services.

Best Laser cutting services by Cyclotron Industries. We offer high precision, fast and accurate laser cutting solutions for any kind of metal applications

What Are High Precision Laser Cutting Services?

- High-precision laser cutting uses focused fiber or CO₂ lasers and CNC motion to cut metals, plastics, and ceramics with micron-level accuracy.

- The non-contact beam creates very narrow kerfs, minimal heat-affected zones, and smooth, burr-free edges, cutting down finishing and inspection time. Industries such as aerospace, medical devices, and electronics rely on its repeatability and fast, scalable production.

Precision laser cutting delivers ultra-accurate, repeatable cuts for parts where tolerances, surface quality, and thermal control are critical. Using high-power fiber or CO₂ lasers with advanced motion systems, it produces clean, burr-free edges and complex geometries, reducing finishing work and ensuring components meet stringent performance, safety, and reliability requirements. High precision laser cutting is used in:

- Aerospace components:

Aerospace parts require micron-level accuracy and flawless edges, as even slight deviations can impact the performance or safety. Precision laser cutting offers consistent, stress-free cuts in lightweight alloys and complex geometries, enabling tight tolerances, reduced post-processing, and reliable fitment in applications such as engines, avionics, structural frames, and turbine components. - Electronics and instrumentation:

Electronics manufacturing requires the precise patterns, narrow kerfs, and tight thermal control to protect delicate substrates. Precision laser cutting enables the creation of fine apertures, accurate PCB profiles, and burr-free holes for connectors and shielding, while minimizing the heat-affected zones that can cause delamination. This can support the sensors, microelectronic enclosures, precision terminals, and instrument components where electrical performance and reliable assembly depend on exact dimensions and repeatability. - Medical equipment:

Medical devices require immaculate cuts, traceable tolerances, and minimal thermal damage to meet safety and regulatory standards. Precision laser cutting achieves burr-free edges and exact profiles for implants, surgical tools, diagnostic housings, and microfluidic channels. By reducing machining marks and contamination, it lowers the number of finishing and sterilization steps, enabling the production of consistent, biocompatible parts with documentation-ready repeatability for regulated manufacturing environments and validation. - Precision sheet metal assemblies:

Sheet-metal assemblies rely on precise edge quality, accurate hole placement, and consistent bend lines to achieve the tight fits and maintain structural integrity. Precision laser cutting produces burr-free profiles, accurate nesting, and exact corner radii that improve weld and fastening quality while minimizing alignment work. This accuracy reduces the material waste, lowers the assembly time, and enables the creation of lighter, stronger structures for industrial, architectural, and consumer applications.

Best Laser cutting services by Cyclotron Industries. We offer high precision, fast and accurate laser cutting solutions for any kind of metal applications

Key Features of High Precision Laser Cutting

High-precision laser cutting, combined with the advanced optics, stable laser output, and precise motion control, produces consistent, repeatable parts with razor-sharp edges and micron-level tolerances.

It is ideal for industries that require flawless finishes and exact fits, such as electronics and medical devices, where every micron and surface matter, and precision counts.

Here are the essential features of high-precision laser cutting.

- Micron-Level Accuracy:

Micron-level accuracy means that parts are produced exactly as designed, down to the smallest fractions of a millimetre. That predictability makes assemblies fit the first time, every time, and keeps products performing as expected. Engineers rely on it for critical components because even a small error can cause failures or result in costly rework. - Fine Edge Quality

Fine edge quality, achieved through high-precision lasers, provides clean, smooth edges without burrs, so parts often require minimal extra finishing. Because there’s little heat damage, surfaces keep their look and fit. That saves time in inspection and assembly, and helps when the edge is visible on the finished product. - Laser Stability and Motion Control

Stable lasers and precise motion control ensure the beam remains focused and the cutting head remains steady. That combo lets machines trace tiny curves and complex shapes cleanly, without wobble or chatter. The outcome is consistent kerf width, accurate details, and fewer rejected parts, especially useful for delicate or tightly featured designs. - Ideal for Thin and Delicate Materials

These lasers are gentle enough to cut thin metal sheets, including those as thin as 0.3 mm stainless steel or aluminium, without warping. Fine control of power ensures the heat-affected zone remains small, allowing the metal to retain its strength and finish. It’s a reliable method for producing small, delicate parts in large quantities.

Materials Used in High Precision Cutting

Precision materials combine cutting-edge lasers with metallurgical expertise, delivering flawless edges, microscopic accuracy, and repeatable precision across various industries. This enables innovation, tighter assemblies, and components engineered for performance and long-term reliability.

- Stainless Steel (SS):

Stainless steel offers exceptional corrosion resistance, biocompatibility, and a consistent surface finish, making it ideal for medical devices, food processing components, and electronic enclosures. High-precision laser cutting produces the smooth, burr-free edges and accurate tolerances, preserving hygienic surfaces and critical dimensions for assemblies that require cleanliness, durability, and long-term dimensional stability. - Mild Steel (MS):

Mild steel offers the combination of machinability, strength, and cost-effectiveness required for precision industrial assemblies that demand structural integrity and tight fits. Laser cutting yields repeatable kerf widths and minimal warping, enabling the production of close-tolerance parts for fixtures, brackets, and housings. Post-process treatments and careful fixturing ensure dimensional accuracy and reliable assembly performance over time. - Aluminium:

Aluminium’s low density, excellent thermal conductivity, and natural corrosion resistance make it a suitable material for lightweight, precision components in aerospace and automotive products. Fiber laser cutting delivers clean profiles with minimal heat-affected zones, preserving material strength and surface finish. Accurate nesting reduces waste, while finishing preserves tolerance-critical features for peak performance in weight-sensitive assemblies. - Copper & Brass:

Copper and brass deliver the superior electrical conductivity and thermal transfer for precision conductive or reflective components. Laser cutting handles thin sheets and intricate profiles while minimizing dross and distortion. Excellent edge quality preserves conductive pathways and optical surfaces; controlled post-cut annealing and handling ensure conductivity, long-term reliability, and consistent performance.

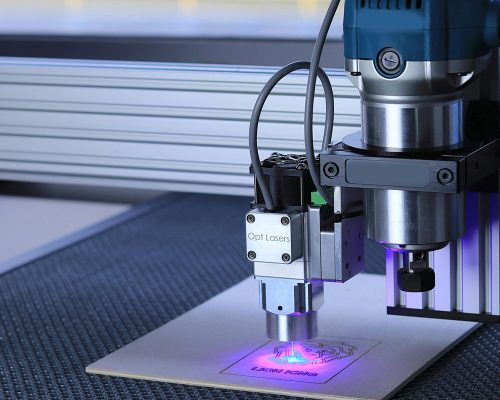

At Cyclotron, we deliver fast, accurate precision laser cutting using modern machines, expert engineers, and customized solutions for industries like automotive, aerospace, and construction. Here is why you should invest in Cyclotron for Fiber laser cutting:

Advanced Fiber Laser Cutting Machines

We use up-to-date fiber lasers that give clean, precise cuts fast, so your parts need less finishing and stay consistent.

Expertise in Precision Engineering

Our technicians understand materials and tolerances. Our dedicated engineers fine-tune settings and inspect jobs so parts fit and work exactly as intended.

Serving Multiple Industries with Custom Solutions

We help automotive, aerospace, construction, and industrial clients. We adapt processes to your drawings, timelines, and special requirements.

Best Laser cutting services by Cyclotron Industries. We offer high precision, fast and accurate laser cutting solutions for any kind of metal applications

Laser cutting services

Laser cutting services in Pune

Fiber laser cutting services in Pune

Metal laser cutting services in Pune

Laser cutting for sheet metal parts

CNC Laser cutting services in Pune