Custom laser cutting in Pune

Custom laser cutting in Pune

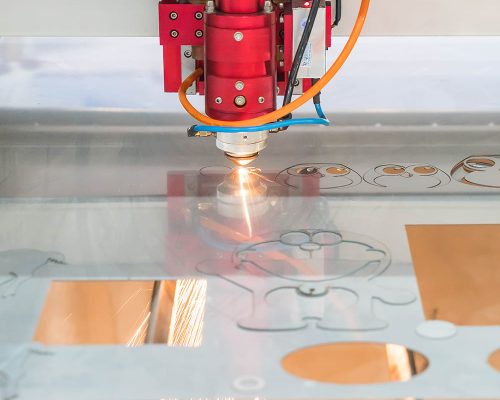

Get the best Custom laser cutting in Pune from Cyclotron Industries. All types of custom laser cutting parts for MS, SS, Aluminium material at best rates.

- Custom laser cutting transforms your ideas into tangible parts with speed and precision. Instead of long lead times and costly tooling, modern laser machines follow your DXF or DWG files and cut exactly what you designed, even tiny holes, thin slits, or complex curves

- That makes laser cutting perfect whether you’re testing a new prototype, producing a small batch or running a steady production line. The result is clean edges, tight tolerances, and less rework which saves time and money.

For designers and engineers, it means fewer compromises: the shape you draw is the shape you get. In India, the use of improved fiber-laser machines and skilled operators provides reliable delivery and competitive pricing.

Best Laser cutting services by Cyclotron Industries. We offer high precision, fast and accurate laser cutting solutions for any kind of metal applications

What Are Custom Laser Cutting Services?

- Custom laser cutting is a fabrication service that utilizes CNC-driven lasers to cut sheet or tube materials precisely according to a customer’s digital design. You submit vector files (commonly DXF or DWG), the shop prepares and nests the parts to use material efficiently, and the laser follows the tool path to cut parts with high repeatability.

- Compared with traditional mechanical cutting or stamping, laser cutting needs no dies, can switch designs instantly, and produces minimal distortion.

- It works for prototypes and production runs, and is especially valuable when parts have fine detail, internal cutouts, or require smooth, burr-free edges.

Benefits of Custom Laser Cutting

Custom laser cutting is popular because it combines precision, flexibility, and speed. Below are the key benefits explained easily.

- High Precision and Repeatability: Laser systems hold tight tolerances across dozens or thousands of parts. The CNC control and focused beam mean every copy matches your CAD drawing closely — ideal when fitting parts together is critical.

- Complex Shapes Made Simple: Intricate patterns, internal holes, and delicate features are straightforward for a laser. Shapes that are expensive or impossible with punches, saws, or waterjet become routine with laser cutting.

- Speed and Efficiency: Without dies or setup for each geometry, lasers switch jobs quickly. Short runs and urgent prototypes can be turned around fast, while nesting software reduces material waste for larger runs.

- Clean Finishing: Laser-cut edges are smooth and mostly burr-free, which reduces grinding or filing. That saves hours of secondary finishing, and gives parts a higher-quality, ready-to-assemble appearance.

- Multi-Material Capability: Modern fiber lasers and appropriate power settings let you cut steel, stainless, aluminum, copper/brass, and non-metals like acrylic. That versatility helps suppliers serve diverse industries from one workshop.

- Cost-Effective for Many Runs: For prototypes and low-to-medium volume production, custom laser cutting often outperforms stamped or machined parts because tooling costs are eliminated. The predictable, automated process also reduces labor costs per part.

Materials We Process for laser cutting

We handle a broad set of materials commonly needed in fabrication:

- Mild Steel (MS): Mild steel is Strong, affordable, and easy to weld. Suitable for structural brackets, frames, and general fabrication. Laser cutting produces clean edges with minimal warping for typical thicknesses.

- Stainless Steel (SS): Stainless steel is corrosion-resistant and hygienic, making it a preferred material for use in food, pharmaceutical, and architectural applications. Laser cutting keeps the finish intact and delivers precise, repeatable parts.

- Aluminium: It is a Lightweight and non-magnetic, ideal for enclosures, panels, and transport components. Aluminium requires the correct power and cutting gas settings to prevent burrs and edge discoloration.

- Copper & Brass: Copper and brass are used in electrical and decorative parts. Copper’s high reflectivity and thermal conductivity require tuned processes; however, modern lasers can handle thin to moderate thicknesses well.

- Acrylic & Non-metals: Excellent for signage, light diffusers, and displays. Laser produces nice, polished edges on acrylic and crisp cuts on many plastics, but some plastics require special ventilation and care.

- Specialty Materials: Depending on equipment, some shops also process coated metals, composite sheets, or thin ceramics. Always check material compatibility and edge quality expectations to ensure optimal results.

Best Laser cutting services by Cyclotron Industries. We offer high precision, fast and accurate laser cutting solutions for any kind of metal applications

How the Custom Laser Cutting Process Works

A simple, reliable workflow keeps production smooth and predictable:

- Design Received (DXF/DWG): You provide CAD files, PDFs with vector art, or core design specs.

- File Check & Optimization: The operator verifies geometry, corrects minor issues, and prepares the file for nesting to minimize scrap.

- Material Setup & Nesting: Sheets or tubes are loaded, and parts are nested in software for efficient cutting.

- Laser Cutting Execution: The CNC laser follows the tool paths. Operators monitor run conditions (power, gas, speed).

- Quality Inspection: Parts are measured for critical dimensions and checked for edge quality and burrs.

- Post-processing (if needed): Deburring, bending, welding, or surface finishing is performed according to the specified requirements.

- Packing & Delivery: Parts are carefully packed and dispatched with packing lists and drawings.

Clear communication at the file stage speeds everything, including material thickness, finish, and tolerance expectations in the order.

Custom Laser Cutting Services in India

India’s industrial environment has largely adopted advanced fiber-laser equipment, which has improved both speed and quality. Cities like Pune, Chennai, Ahmedabad, and Bengaluru have professional workshops that serve automotive suppliers, OEMs, and architects.

Local consumers benefit from shorter lead times and lower logistical costs, thanks to domestic supplier networks. Many fabricators offer one-stop fabrication services, which encompass laser cutting, bending, welding, and finishing, thereby reducing coordination time and streamlining procurement.

Why Choose Cyclotron for Custom Laser Cutting

Cyclotron stands out through a mix of technology, experience, and customer focus:

- Modern Machines: We use current-generation fiber lasers that deliver precise cuts and low operating cost.

- Experienced Engineers: Our team inspects files, suggests nesting improvements, and flags manufacturability issues before cutting starts.

- End-to-End Support: From file cleanup to final finishing and assembly, we provide comprehensive fabrication services, ensuring you receive ready-to-use parts.

- Quality Monitoring: Digital controls and inspection protocols ensure each batch meets tolerance and surface requirements.

- Fast Turnaround: Efficient scheduling and local stock materials enable us to meet the tight deadlines without compromising quality.

- Responsive Service: We explain material and tolerance trade-offs in simple terms and provide quick quotes, allowing you to plan confidently.

Choosing a partner that reviews your file and suggests small design changes can save material and avoid costly rework.

Best Laser cutting services by Cyclotron Industries. We offer high precision, fast and accurate laser cutting solutions for any kind of metal applications

Laser cutting services

Laser cutting services in Pune

Fiber laser cutting services in Pune

Metal laser cutting services in Pune

Laser cutting for sheet metal parts

CNC Laser cutting services in Pune