Copper laser cutting in Pune

Copper laser cutting in Pune

Best Copper Laser cutting in Pune by Cyclotron Industries. We have expert team for laser cutting solutions for MS, SS, Aluminium& Copper. Cyclotron is a Industry leader in all types of Metal cutting services.

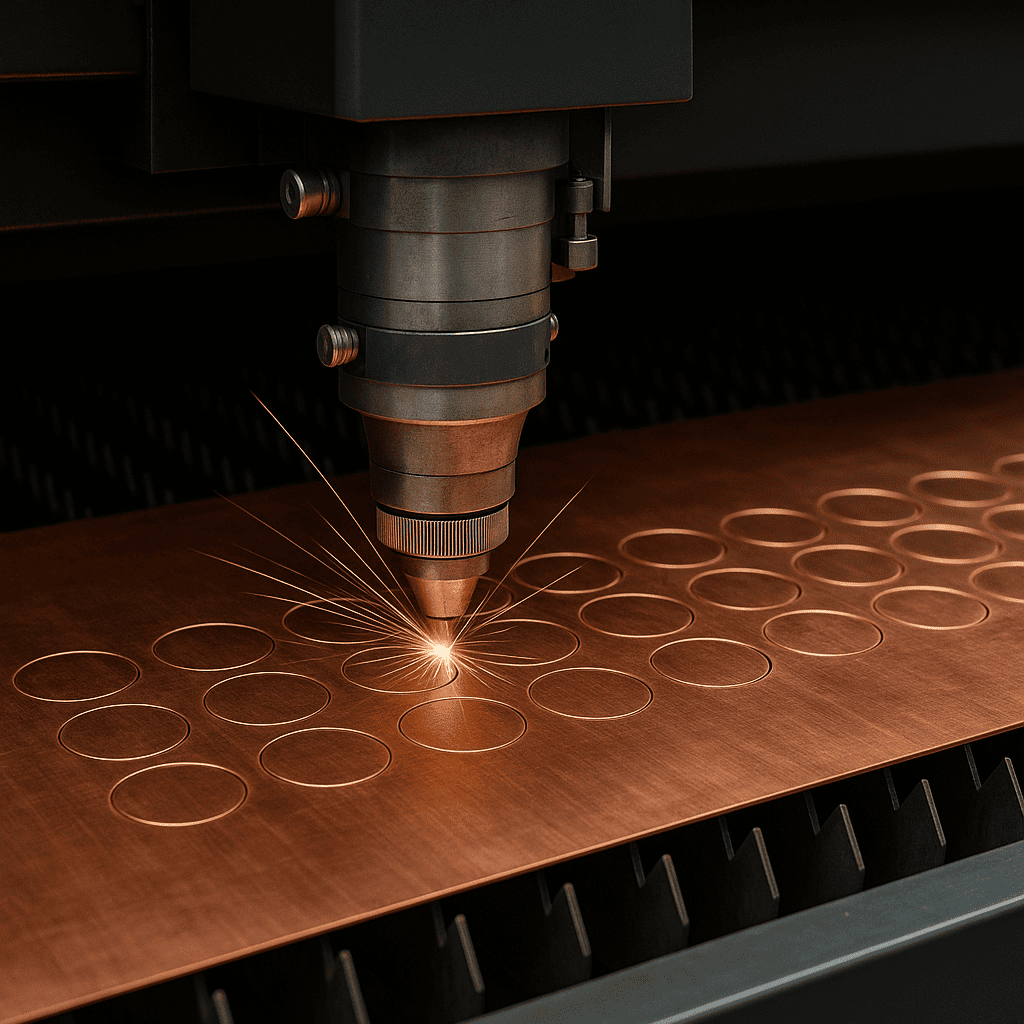

Copper laser cutting

Copper, also known as the yellow metal, is a significant component of energy technologies, including solar panels and batteries. Like Aluminum, Steel, and Gold, Copper is one of the popular metals that possess reflective properties. Copper laser cutting is a challenging task that requires specialized skills and experience to produce products with precision and quality.

- Copper can also be cut with other techniques, such as waterjet, plasma, or mechanical shearing. But why does the modern manufacturing industry rely on copper laser cutting services? Read this blog to know why fiber laser cutting is the most optimal solution to create copper components.

Best Laser cutting services by Cyclotron Industries. We offer high precision, fast and accurate laser cutting solutions for any kind of metal applications

Introduction to Copper Laser Cutting

- Pure Copper is a perfect blend of strength, conductivity, corrosion resistance, and plasticity. Overall, a perfect material for manufacturing industries to work with. But did you know that copper is amongst the most challenging materials to handle in metal fabrication? Yes, that's true!

- Due to its high absorption and reflective nature, it often damages the laser cutters. Our skilled labor and experts at Cyclotron know how to craft precise components with intricate designs using copper sheet laser cutting, maintaining high quality and precision.

- This article discusses the importance of copper in electrical, electronic, and industrial applications. Also, find out why copper laser cutting services are increasingly preferred over mechanical methods.

What is Copper Laser Cutting?

The automated Copper laser cutting process involves generating a high-powered laser beam that strikes a tiny spot on the copper sheet along the pre-programmed cutting path.

The high-energy beam heats, melts, and vaporizes the sheet until the cutting part is obtained.

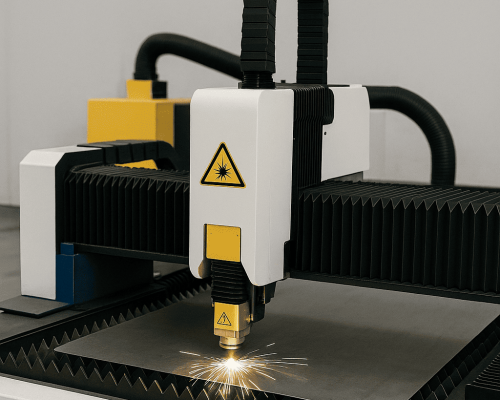

Unlike traditional CNC machining, which involves physical labor, copper laser cutting is a non-contact thermal process.

It does not require any expensive tools to mill away the material. Instead, it absorbs the heat emitted by laser beams, followed by nitrogen-assist gas, to produce components with precision and clean cuts.

Typically, copper laser cutting is performed with a fiber laser due to its high thermal conductivity, softness, and reflective properties.

Modern fiber laser systems can easily address the high reflectivity of copper through optimized beam delivery, wavelength selection, and material modification.

Best Laser cutting services by Cyclotron Industries. We offer high precision, fast and accurate laser cutting solutions for any kind of metal applications

Advantages of Copper Laser Cutting Services

High Precision and Accuracy: Fiber laser offers high conversion & energy efficiency while targeting a small spot on copper sheets. It is ideal for applications in the construction, electrical, decorative, and signage industries that require micro-level precision components.

Clean, Burr-Free Edges: Copper laser cutting is usually performed with a fiber laser, which uses an assist gas (oxygen/ nitrogen) to produce copper parts with clean cuts and burr-free edges.

Minimal Thermal Distortion: A laser beam is focused onto a tiny spot on a copper sheet to avoid thermal distortion and a large HAZ (Heat-affected zone).

Efficient for Thin Sheets and Intricate Designs: Copper laser cutting services are the most reliable option for cutting through thin copper sheets. However, thicker sheets require advanced machine setup and high-power systems.

Reduced Material Waste and Improved Productivity: The non-contact and fully automated copper laser cutting process not only preserves its strength but also accelerates productivity

Copper Grades Suitable for Laser Cutting

Fiber laser technology can handle a wide array of copper grades, offering high conductivity, copper content, and anti-corrosion properties. Here’s the list of some most popular copper grades and alloys used by electrical, electronics and other manufacturing units.

- Electrolytic Tough Pitch (ETP) Copper (C11000); used for making busbars, connectors, and other electrical components.

- Oxygen-Free High Conductivity (OFHC) Copper (C10100/ C10200); used for high vacuum & current applications.

- Beryllium Copper (CuBe) is a reliable option for load cells, plastic molds, and other applications.

- Phosphor Bronze (C51000) is used to make electrical components that require high fatigue resistance.

Challenges in Copper Laser Cutting and Their Solutions

Undoubtedly, pure copper offers numerous benefits, including high conductivity, magnetic properties, and corrosion resistance. But at the same time, it poses significant challenges, such as reflectivity and absorption issues, which are difficult to address.

So, which is a better option for copper laser cutting operations? Is it CO2 or fiber lasers?

Well, the most suitable option is fiber laser cutters, as they perform exceptionally well on reflective materials like copper and aluminum. Unlike CO2, this contactless cutting method offers high energy efficiency, precision cutting, and a narrow kerf at high cutting speed.

- Managing heat input and surface oxidation: It’s the other major challenge of copper laser cutting face in Pune and across India.

- High-speed copper laser cutting operation may result in material warping and uneven cuts. Using oxygen as an auxiliary gas may form a copper oxide layer, which, in turn, can cause high-heat-affected zones. Though it can be overcome by using nitrogen-assist gas and maintaining a perfect balance of speed, laser power, and pressure.

- Maintaining dimensional stability in thin copper sheets: Thin copper sheets are prone to distortion, warping, or twisting due to their low mechanical strength and high stress sensitivity. To counteract these challenges, symmetrical copper distribution and structural rigidity are recommended. Annealing and applying gradual pressure while bending or mounting can also help stabilize dimensions during the copper laser-cutting operation.

Factors Affecting Copper Laser Cutting Cost

The cost of copper laser cutting depends on internal and external factors, including shipping, service charges, and taxes. However, it’s the internal factors that primarily influence the overall cost-

- Material grade and thickness

- Cutting complexity and design precision

- Laser power and type (fiber laser preferred)

- Quantity and turnaround time

The other significant factors influencing the cost of copper laser cutting include machine runtime, labor, speed, assist gas, cutting path, and level of advancement.

Why Choose Cyclotron for Copper Laser Cutting Services

Cyclotron is one of the top-notch copper laser cutting companies in Pune with years of experience and expertise in cutting copper, brass, and other non-ferrous metals. With our experienced engineering support and specialized fiber laser systems for reflective materials, we promise to manufacture copper components with consistent edge quality and tight tolerances. Cyclotron offers

- Precision Copper laser cutting

- Fast delivery from prototype to mass production

- Dedicated Support

- Competitive prices

Best Laser cutting services by Cyclotron Industries. We offer high precision, fast and accurate laser cutting solutions for any kind of metal applications

Laser cutting services

Laser cutting services in Pune

Fiber laser cutting services in Pune

Metal laser cutting services in Pune

Laser cutting for sheet metal parts

CNC Laser cutting services in Pune