Cnc laser cutting services in Pune

Cnc laser cutting services in Pune

Cyclotron Industries provide the best CNC laser cutting services in Pune. Other services we provide are fiber laser, metal laser cutting, steel laser cutting , etc

The globally accepted CNC laser cutting process has become crucial for high-precision fabrication.

Many dynamic industrial sectors like automotive, aerospace, defense, etc., are adopting CNC laser cutting due to its high precision & scalability.

Let’s quickly walk through this article to know how CNC laser cutting companies are opening up a vast pool of opportunities for various businesses across India.

Best Laser cutting services by Cyclotron Industries. We offer high precision, fast and accurate laser cutting solutions for any kind of metal applications

Introduction to CNC laser cutting

- CNC laser cutting is known for phenomenal accuracy and high-speed operation. The advanced technology has brought a huge revolution in new-age industries

- CNC laser cutting services have become quintessential for high-stakes sectors, including aerospace, electronics, and construction.

- The automated CNC laser cutting process has enabled SMBs/MNCs to achieve significant growth by accelerating the production cycle and reducing waste. Read this article to understand the CNC laser cutting concept, its applications, and the benefits over traditional cutting methods.

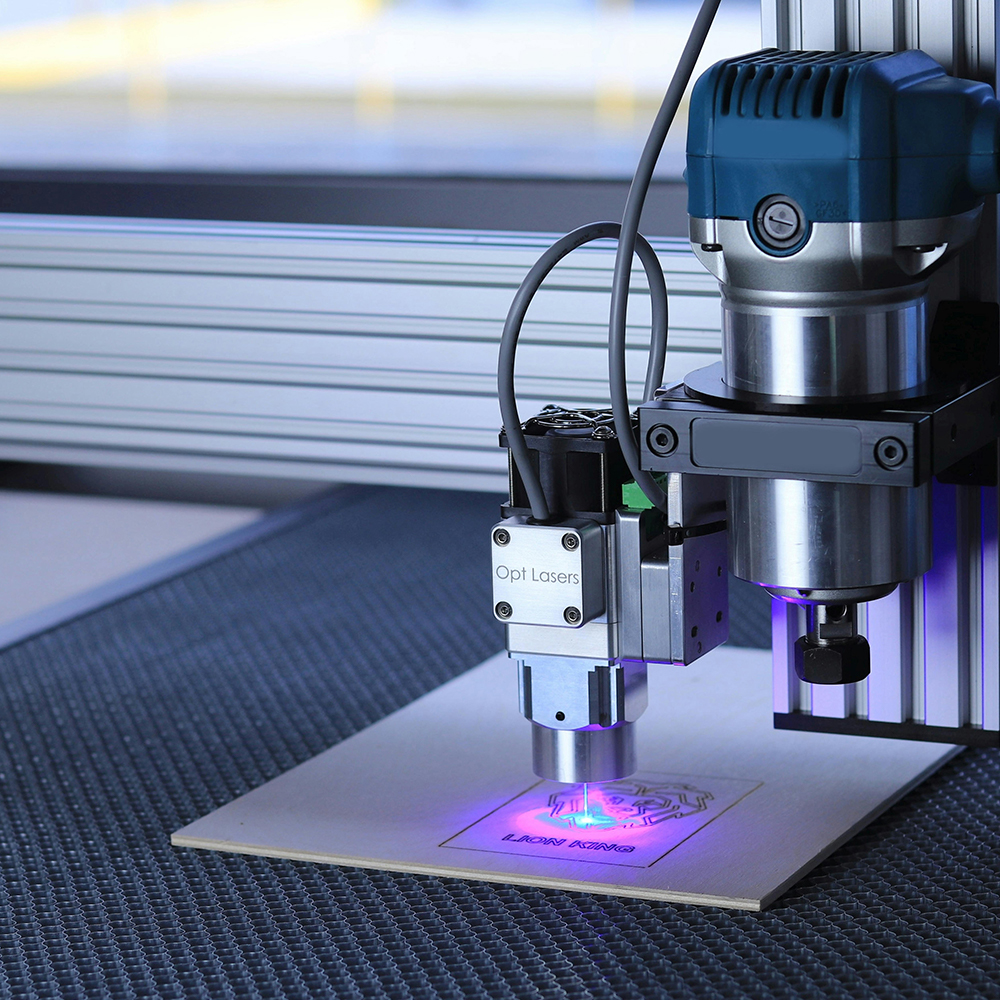

As the name suggests, CNC Laser Cutting is operated using a fully automated CNC (Computer Numerical Control) system offering high precision and accuracy.

This fabrication method uses a high-power laser beam to cut through different materials.

CNC, the brain component, translates the CAD files into G-code for the precise movement of the laser head.

Unlike the traditional contact-based cutting techniques, CNC laser cutting is a thermal process that minimises errors, material distortion, tool wear, and post-processing.

Basically, there are three types of CNC laser cutting services, including

| Fiber Lasers | CO₂ Lasers | Hybrid |

|---|---|---|

| Based on solid-state technology, fiber lasers are ideal for cutting reflective materials like steel, aluminium, etc. | Uses a gas mixture to cut through non-metallic materials like acrylic and wood. | This versatile cutting method can cut through both metal and non-metal sheets, depending on their properties. |

CNC Laser Cutting Process Explained

Design & CAD/CAM Programming

In the initial phase, the CNC (computer numerical control) component translates the design created from CAD software into G-code. This G-code carries all the details, including cutting parameters, laser power, focus, frequency, desired cutting path of the laser beam.

Material Setup & Alignment

It’s the next step where the material is carefully aligned and clamped for stable operation. The CNC system calibrates the focal point of the high-powered beam to produce parts with clean cuts.

Laser Cutting Operation

The CNC laser cutting process starts with the G-code execution. An intense laser beam is generated and focused on the surface until the material sheet vaporizes. Then, an assisting gas (oxygen/ nitrogen) is ejected to blow away the molten metal.

Quality Inspection & Finishing

It’s the final phase where the laser-cut parts are thoroughly inspected for clean cuts and a polished look. Most of the time, CNC laser cutting produces minimal burr and doesn’t require post-treatments like protective coating application or deburring.

Best Laser cutting services by Cyclotron Industries. We offer high precision, fast and accurate laser cutting solutions for any kind of metal applications

Advantages of CNC Laser cutting

Besides precision, speed, and accuracy, CNC laser cutting offers numerous benefits over conventional cutting methods like plasma and fusion. Take a look!

- High Precision & Repeatability: Pre-programmed CNC laser cutting services can easily deliver smooth cuts with uniform edges at repetitive rates.

- Complex Geometry Capability: Unlike conventional cutting methods, the focused laser beams can easily cut intricate designs with complex geometries, shapes, or patterns.

- Faster Production & Automation: This high-speed & fully automated laser cutting method not only streamlines the workflow but also boosts production cycles.

- Minimal Material Waste: The advanced nesting software and narrow kerf width reduce the material wastage to almost zero.

- Smooth Edges & Minimal Post-Processing: The CNC system ensures that laser-cut parts have smooth/uniform edges and don’t require any costly secondary treatments such as deburring or anodising.

Materials Suitable for CNC Laser Cutting

The CNC laser cutting process is known for its versatility to handle a wide range of materials, including both metals and non-metals. Here’s the list of some of the most common materials used in CNC laser cutting.

- Mild steel & stainless steel: These ferrous metals, when used with CNC laser cutting, deliver metal parts with precise cuts and smooth edges.

- Non-ferrous metals: Reflective metal materials like Brass, titanium, aluminium, and copper usually require a high-power fiber laser for producing uniform edges.

- Acrylic sheets: Plexiglass/ acrylic sheets are known for producing perfect parts with a flame-polished look.

CNC Laser Cutting vs Traditional Cutting Techniques

| Features | CNC Laser Cutting | Plasma Cutting | Mechanical Cutting |

|---|---|---|---|

| Speed | Very high for thin materials. | Works on low speed to maintain quality. | Slow. |

| Accuracy | Very high for parts with intricate designs. | Average accuracy decreases with material thickness. | High; rest, it depends on the material quality. |

| Cost | Low set-up cost; it relies only on a digital file. | Low. | Very high; requires physical tools, custom dies & manual labour. |

Factors Affecting CNC Laser Cutting Cost

Need a cost analysis? Although cost is directly proportional to machining time, there are various factors influencing the CNC Laser Cutting Cost.

- Material type & thickness: Reflective and more complex materials like copper and brass need slower speeds & high laser power, which increases the machine time.

- Cutting complexity: Complex designs require specialised programming, more piercings, long corners, and cut lines as compared to simple designs. All these factors increase the overall cost.

- Production volume: Prototype jobs require a high initial set-up cost as compared to bulk volume productions. Mass production reduces the price per unit.

- Machine type & operator efficiency: Operator’s skills and the machine’s efficiency also reduce the material wastage, time, and energy consumption.

Why Choose Cyclotron for CNC Laser Cutting Services

Based in Pune, Cyclotron is one of the leading CNC laser cutting companies in India. With advanced CNC fiber laser cutting machines and an experienced team, Cyclotron offers tailored solutions for both small and large jobs. Still not convinced? Take a look at solid reasons to choose Cyclotron for your upcoming CNC laser cutting project.

- Advanced Equipment

- One-stop Procurement Management

- Guaranteed tight tolerances

- Dedicated support

- Competitive prices

Best Laser cutting services by Cyclotron Industries. We offer high precision, fast and accurate laser cutting solutions for any kind of metal applications

Laser cutting services

Laser cutting services in Pune

Fiber laser cutting services in Pune

Metal laser cutting services in Pune

Laser cutting for sheet metal parts

CNC Laser cutting services in Pune