Automotive laser cutting services

Automotive laser cutting services in Pune

Best Automotive Laser cutting services in Pune by Cyclotron Industries. We have expert team for laser cutting solutions for MS, SS, Aluminium & Copper. Cyclotron is a Industry leader in all types of Metal cutting services.

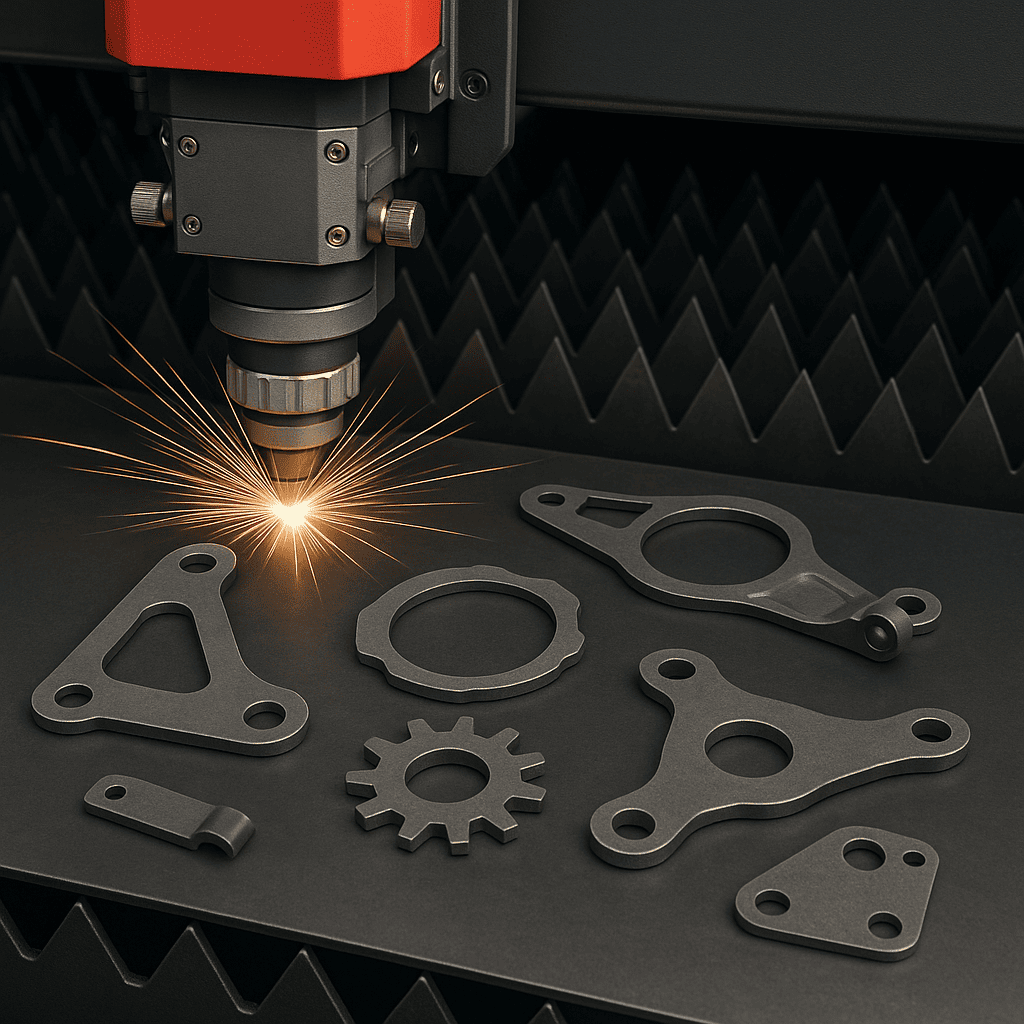

Automotive laser cutting

In automotive manufacturing, laser cutting delivers the razor-sharp accuracy, repeatable dimensions, and clean edges across the materials such as steel, aluminium, and composites. Its speed and automation reduce the lead times and scrap, while minimal heat-affected zones preserve part strength and finish.

The complex geometries, tight tolerances, and high-volume runs become practical and cost-effective when the laser systems handle the cutting. Beyond raw efficiency, laser cutting simplifies downstream assembly and lowers the need for secondary machining, helping engineers move from prototype to production with confidence. For vehicle components where reliability and fit matter, laser cutting is no longer an option; it’s a standard that helps automakers scale quality at speed.

This blog post briefly covers everything you need to know about automotive laser cutting services, why it’s essential to the automotive industry, and more.

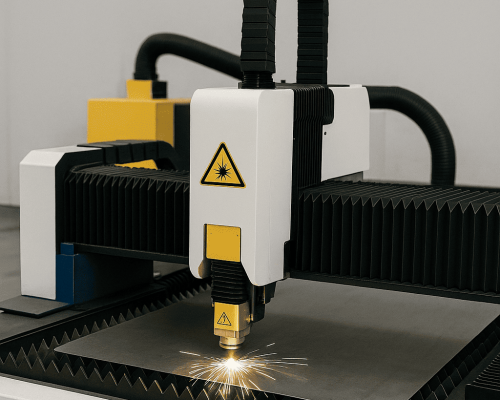

Best Laser cutting services by Cyclotron Industries. We offer high precision, fast and accurate laser cutting solutions for any kind of metal applications

Why Laser Cutting Is Essential for the Automotive Industry?

- High accuracy: Laser cutting delivers the consistently tight tolerances and micron-level precision, ensuring critical automotive components fit and function without post-processing. This accuracy reduces assembly errors, improves vehicle performance, and supports the use of safety-critical parts.

- Clean edges: Laser cutting produces smooth, burr-free edges with minimal dross, eliminating many secondary finishing steps. For the automotive assemblies, flawless edge quality improves sealing, welding, and paint adhesion while reducing inspection time.

- Fast production: High-speed laser systems can rapidly cut parts with automated loading and nesting, shortening cycle times and boosting throughput. Quick setup changes and minimal tooling reduce downtime between jobs, making laser cutting ideal for mixed-model, just-in-time automotive manufacturing.

- Minimal distortion: Laser cutting concentrates heat in a narrow kerf, limiting the heat-affected zone and preserving material properties.

- Ideal for complex shapes: Laser cutting excels at intricate contours, fine slots, and internal features that are difficult with traditional tools. The non-contact beam follows tight radii and tiny piercings without tool wear, enabling lightweight components.

Precision Laser-Cut Automotive Components

We specialize in cutting automotive parts with our advanced laser cutting technology. Our process provides accuracy, durability, and consistency. We help manufacturers and custom builders achieve reliable performance and sleek designs on every vehicle parts

Brackets & Mounting Plates

We laser-cut brackets and mounting plates that provide strong support for various automotive assemblies. These parts are precision-machined to fit perfectly, ensuring stability and long-lasting performance across all vehicle types.Chassis Components & Reinforcements

Our laser-cut chassis components add strength and reliability to the vehicle’s frame. Reinforcements are designed to handle stress and improve safety, giving cars and trucks the durability they need for everyday use and demanding conditions.Sheet Metal Body Parts

We produce sheet metal body parts with clean edges and accurate dimensions. Laser cutting allows us to create panels, doors, and other body sections that fit seamlessly, reducing finishing work and improving overall vehicle appearance.Engine & Transmission Support Parts

Engine and transmission support parts require exact precision, and that’s where our laser cutting in Pune stands out. We deliver components that securely hold critical systems, providing smooth operation and reducing wear to support long-term vehicle performance.Exhaust System Components:

Our laser-cut exhaust system components are built to withstand heat and pressure. From flanges to pipe sections, each part is cut with accuracy, helping vehicles maintain efficiency, reduce emissions, and perform reliably on the road.Interior Metal Parts:

We also produce interior metal parts, including seat frames, dashboard supports, and trim reinforcements. Laser cutting ensures these components are lightweight yet strong, contributing to comfort, safety, and a refined finish inside the vehicle.Prototyping Parts for New Models:

For new vehicle designs, we provide laser-cut prototyping parts that help engineers test and refine ideas quickly. These components allow faster development cycles, ensuring innovative models reach production with accuracy and confidence in performance.Custom Automotive Components:

Each project is unique, and we provide bespoke automotive solutions that are tailored to specific needs. Whether it’s a particular design or a specialty product, our laser cutting in Pune guarantees precision, flexibility, and quality for completely personalized solutions.

Best Laser cutting services by Cyclotron Industries. We offer high precision, fast and accurate laser cutting solutions for any kind of metal applications

Materials Used in Automotive Laser Cutting

Here is brief information about the types of materials used in automotive laser cutting:

- Mild Steel (MS)

Mild steel (MS) is a cost-effective, strong, and widely used material for structural automotive parts, brackets, and chassis reinforcements. Its predictable weldability suits production runs and repairs. For EVs and modern vehicles, MS offers durable frames where weight isn’t critical. We provide precise laser cutting in Pune for consistent, affordable components. - Stainless Steel (SS – 304/316)

Stainless steel (SS – 304/316) delivers excellent corrosion resistance and strength for exhaust parts, fasteners, and decorative trim. Its durability supports a long service life in harsh environments, which is valuable for EV thermal management and modern vehicle longevity. Choose laser cutting for automotive parts when corrosion resistance and finish quality matter. - Aluminum & Lightweight Alloys

Aluminum and lightweight alloys are essential for lightweighting, improving range in EVs, and fuel efficiency in traditional vehicles. They offer high strength-to-weight ratios for body panels, supports, and powertrain mounts. Laser cutting enables the precise, burr-free edges and minimal heat distortion, making these alloys ideal for advanced automotive designs and prototyping. - Galvanized Steel

Galvanized steel combines steel’s strength with a protective zinc coating to resist corrosion in body panels, mounting points, and underbody components. It balances the durability and cost, helping modern vehicles withstand road exposure. For automotive manufacturers and custom builders, laser cutting in Pune ensures accurate profiling without damaging protective coatings. - Copper / Brass (Electrical Components)

Copper and brass are used for electrical components, connectors, and thermal interfaces in ICE and EV systems. Their excellent conductivity supports battery, sensor, and grounding systems, which are critical for EV performance and safety. Laser cutting for automotive parts produces fine detail for electrical fittings, preserving material properties for reliable, durable, secure connections.

Why Do Automotive Manufacturers Choose Us?

- Consistent Quality & Repeatability

In automotive production, every part needs to be exactly the same, no surprises or inconsistencies. We understand how important this is, so we put a strong emphasis on delivering reliable quality, batch after batch. You can count on us for precision and dependability, ensuring your assembly lines run smoothly and you avoid unnecessary rework or delays. - Engineering Support

Our engineering team is here to help you every step of the way. We work side by side with you to make your parts easier to produce, save costs, and perfect the details that matter. With our support, you can sidestep design headaches, work more efficiently, and trust that every component will meet tough automotive standards all while saving valuable time and money. - Fast Prototyping for R&D

Speed is everything when you’re developing new automotive products. That’s why our rapid prototyping services help you test ideas fast, refine your designs, and move ahead with confidence. We’re here to help you speed up development, cut down on risks, and launch your innovations sooner. - Tight Production Deadlines

We know that automotive projects run on tight timelines, where any delay can be expensive. Thanks to our reliable equipment and streamlined processes, we’re able to meet even the most urgent deadlines without sacrificing quality. You can trust us to come through when it matters most. - Integrated Fabrication Services

Everything you need for fabrication is right here from cutting and bending to welding and finishing. By keeping all these services under one roof, we save you time, minimize coordination headaches, and keep production flowing smoothly. With us, you get faster results and the dependable quality you expect at every stage.

Conclusion

Every automotive project deserves the parts that fit perfectly and perform reliably. Laser cutting makes that possible with unmatched accuracy and efficiency. Don’t settle for less work with Cyclotron Industries and experience how precision engineering can transform your production line.

Best Laser cutting services by Cyclotron Industries. We offer high precision, fast and accurate laser cutting solutions for any kind of metal applications

Laser cutting services

Laser cutting services in Pune

Fiber laser cutting services in Pune

Metal laser cutting services in Pune

Laser cutting for sheet metal parts

CNC Laser cutting services in Pune