Aluminium laser cutting in Pune

Aluminium laser cutting in Pune

Cyclotron Industries offers precise Aluminium laser cutting in Pune. Being the leader in laser cutting services in Pune for MS, SS and Aluminium.

Aluminium laser cutting

Did you know that Aluminum laser cutting is not as easy as it seems? The reflective nature and molecular structure of aluminium make it hard to cut with laser beams. But it doesn’t mean it can’t be cut.

Fortunately, the high conductivity of aluminium helps produce clean cuts with polished edges at high speed and under high pressure. Interesting?

This post discusses everything about aluminium laser cutting, including its applications, benefits, challenges, and strategies to improve its effectiveness. Stay tuned!

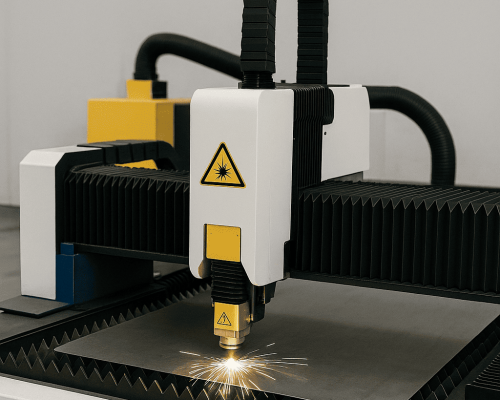

Best Laser cutting services by Cyclotron Industries. We offer high precision, fast and accurate laser cutting solutions for any kind of metal applications

Introduction to Aluminium Laser Cutting in Pune

- Highly precise aluminium laser cutting has become a necessity for modern industries, enabling them to transform aluminium sheets into intricate metal components. This advanced yet cost-effective technique guarantees faster turnaround times for prototype to large volume jobs while maintaining excellent quality.

- Although aluminium is a reflective material, it manages to surpass the AISI grades without damaging the laser cutter. It's one of the major reasons why manufacturing industries like Aerospace, electronics, and construction, etc., are shifting their paradigm to aluminium sheet laser cutting.

- Let's quickly walk through this guide to know why aluminium laser cutting services are preferred over traditional cutting methods.

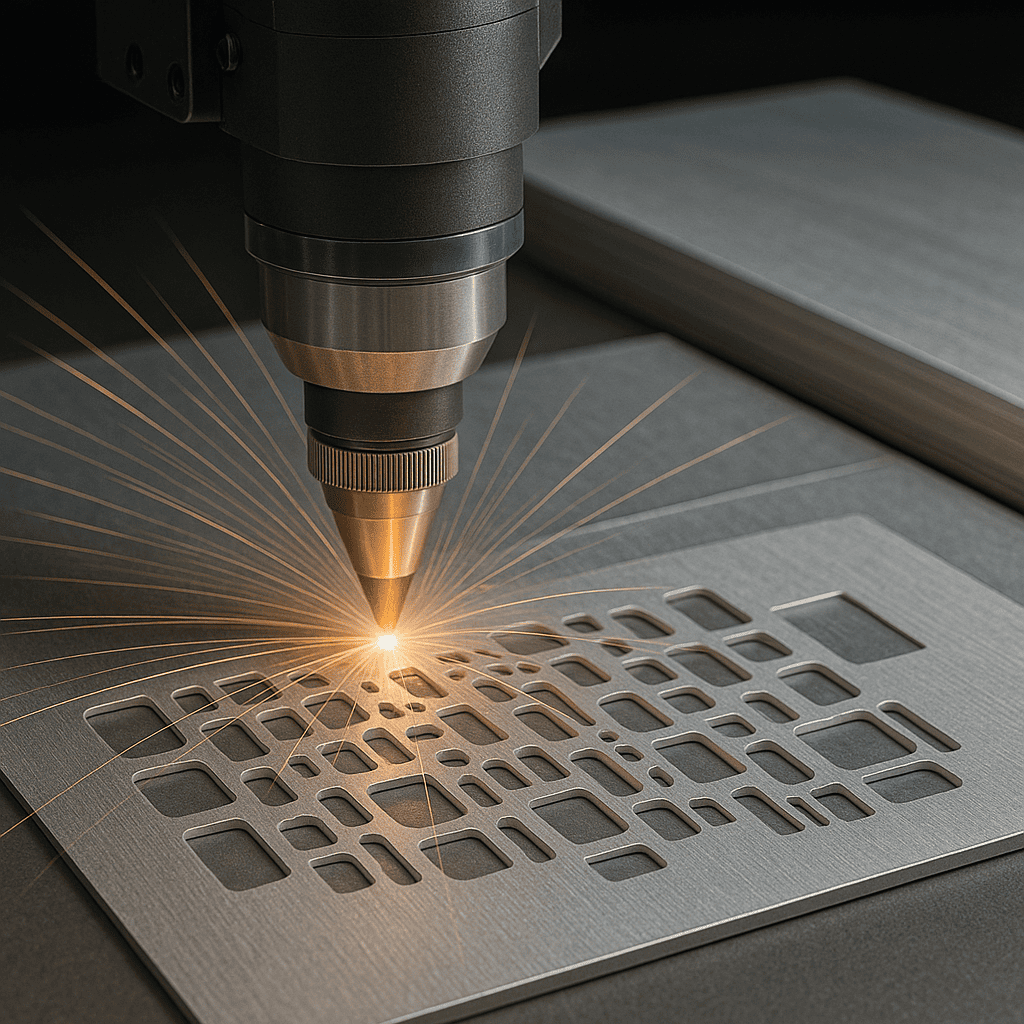

The aluminium laser cutting process involves generating and focusing a high-powered laser beam to precisely cut an aluminium sheet into desired shapes and patterns using a metal-cutting head. It’s an advanced metal fabrication technique that offers various benefits over traditional cutting methods, such as plasma and shearing.

Aluminum sheets can be cut only using either CO2 or fiber lasers, depending on the grade and thickness. However, it delivers precise, high-quality products when cut using fiber laser technology.

Fiber lasers are more effective in terms of speed, accuracy, and material utilization, and are ideal for aluminium thicknesses of 0.5 to 15mm, and even 25mm with high-powered systems.

Most often, aluminium is compared with steel due to its reflective properties. But aluminium laser cutting is more complex and requires specialized tools to produce even cuts and smooth edges. Aluminium has a strong tendency to reflect laser beams, damaging the source and cutting tools. Whereas steel laser cutting gives efficient results with standard C02 and fiber lasers.

Advantages of Aluminium Laser Cutting

Aluminium is used in most modern manufacturing industries due to its high thermal conductivity, non-toxicity, and anti-corrosion properties. Take a look at the key benefits of aluminium laser cutting services.

1.High Precision and Edge Quality: Aluminium laser cutting can achieve tight tolerances, making it ideal for fabricating high-precision metal parts with complex designs or geometries.

2.Minimal Heat Distortion: A high-powered laser beam targets a tiny spot of aluminum sheet to minimize the heat-affected zone and material warping.

3. Smooth, Burr-Free Finishes: This high-speed cutting operation uses assist gas (oxygen/nitrogen) to prevent burr formation and eliminate the need for post-processing treatments.

4. Faster Cutting Speed for Thin Sheets: A fiber laser is the most suitable option for cutting thin aluminium sheets at high speed while maintaining quality and precision.

5. Ideal for Both Prototyping and Mass Production: The fully automated and versatile process accelerates the production of small to large-volume jobs with consistent accuracy.

Aluminium Grades Suitable for Laser Cutting

A variety of industry-specific aluminium grades are available depending on the application. The choice depends on cut quality, corrosion resistance, weldability, and strength requirements. Below is the list of some most preferred grades used by aluminium laser cutting companies.

1.Aluminium 5052 – It is best suited for the fabrication of marine, signage, and robotic components.

2. Aluminium 6061 – Also referred to as an all-around alloy, offers high versatility and is ideal for Aerospace & automotive applications.

3. Aluminium 7075 – This grade is best suited for the manufacturing of components with a high-strength-to-weight ratio. For example, military and defense applications.

4. Aluminium 1050A – known for its purity, this aluminium grade is widely used in the fabrication of decorative & lightweight aluminium parts.

Aluminium Laser Cutting Process

Here’s the detailed process of Aluminium laser cutting, which begins with the generation of high-energy laser beams via CO2 or fiber-optic lasers.

CAD/CAM Design Preparation

In the initial phase, the design of the metal part is prepared using computer-aided design, aka CAD software.

Machine Setup with Fiber Laser Configuration

It’s the setup phase where cutting parameters—power, focus, speed, and others—are configured on the machine. It also includes selecting the right assist gas based on the material grade.

Cutting Operation & Parameter Optimization

Now, the sharp & focused laser beam hits the target spot and vaporizes the sheet along the cutting path.

Deburring, Cleaning & Quality Check

A jet of the assist gas is released to avoid burr formation. Also, the quality is inspected, and, if required, post-processing treatments such as anodizing/coating are performed.

Best Laser cutting services by Cyclotron Industries. We offer high precision, fast and accurate laser cutting solutions for any kind of metal applications

Aluminium Grades Suitable for Laser Cutting

Almost every modern manufacturing industry is leveraging the benefits of the material itself and aluminium laser cutting technology. Here are the key applications of cost-effective, fast aluminium laser cutting services.

Aerospace & Defence Components, such as air panels, frames, and fuselages, are manufactured from high-grade aluminium alloys, such as 7075-T6 and 2024-T3.

Automotive & Transport Equipment – Manufacturers rely on aluminum laser cutting services for lightweight vehicle bodies, chassis, battery trays, and more.

Electrical & Electronic Enclosures rely on aluminum for its high conductivity. It allows the creation of laser-cut heat sinks, enclosures, PCBs, and other assembly components.

Industrial Machinery & Fabrication uses custom aluminum laser-cutting services to manufacture heavy-duty machinery, brackets, and specialized parts.

Signage, Architecture & Decorative Panels use aluminium laser cutting for high precision and quality.

Challenges in Aluminium Laser Cutting and Their Solutions

Aluminium is known for its highly reflective nature, which is why aluminium laser cutting is considered a complex task. Even with an additional coating of a non-reflective material, there is still a high risk of damage to laser cutters if the laser beam bounces back.

The next challenge that often arises in aluminium laser cutting is burr formation. It usually arises due to a lack of experience and expertise in the field.

So, how to overcome these challenges? Here are a few things to keep in mind

- Choose the right laser cutting machine: for burr-free cutting and maintaining edge finish on thicker plates, it is recommended to choose a high-power fibre laser over a CO2 laser.

- Please select the right aluminum grade: High-grade aluminum contains a higher proportion of alloy elements, making it easier to cut while preventing micro burrs and surface oxidation.

- Machine setup, such as focal distance, laser power, etc., also contributes to the quality of aluminium laser cutting.

Why Choose Cyclotron for Aluminium Laser Cutting Services in Pune

It’s quite confusing to choose the best one, especially when most of the aluminium laser cutting companies promise to deliver exceptionally good services.

But you can always rely on Cyclotron for producing exact aluminum cut parts without compromising on quality. As already discussed, aluminium cutting comes with several challenges, and Cyclotron has the experience to provide solutions for simple to daunting tasks. Here’s some solid reasons to work with cyclotron, a leading service provider of aluminium laser cutting in Pune.

- Advanced fiber laser systems designed for reflective metals.

- Expertise in thin and thick aluminium cutting.

- Precision results with minimal post-processing.

- Reliable turnaround times for Pune and pan-India clients.

Laser cutting services

Laser cutting services in Pune

Fiber laser cutting services in Pune

Metal laser cutting services in Pune

Laser cutting for sheet metal parts

CNC Laser cutting services in Pune