Acrylic laser cutting services in Pune

Acrylic laser cutting services in Pune

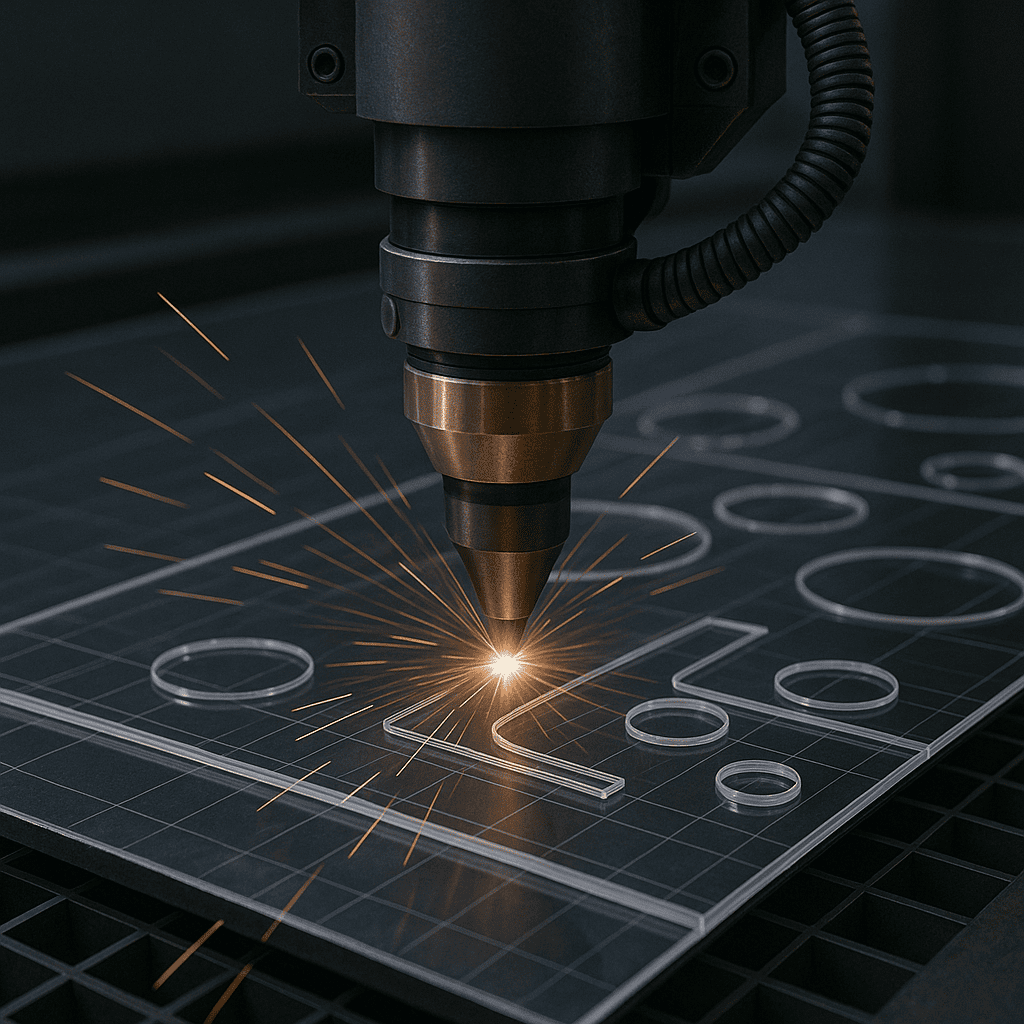

Cyclotron Industries is the leading Acrylic Laser cutting services in Pune. The company has an expertise in acrylic, fiber, metal laser cutting services in Pune.

In the era when industries demand high-precision, quality control, and efficiency, acrylic laser cutting has become a go-to manufacturing process.

Its ability to create visually stunning artworks and precise components has attracted a diverse range of industries.

This comprehensive guide delves into every detail of the acrylic laser cutting process: from its unmatched benefits and cost-effectiveness to the numerous applications.

Join us as we uncover why acrylic laser cutting in Pune is a brilliant yet strategic decision for businesses aiming for excellence!

Best Laser cutting services by Cyclotron Industries. We offer high precision, fast and accurate laser cutting solutions for any kind of metal applications

Introduction to Acrylic Laser Cutting

- Acrylic Laser cutting services in Pune are known for their versatility across various industries, including signage, architecture, electronics, etc.

- The rising demand for acrylic sheet cutting is quite evident over the past few years. Acrylic, also referred to as Plexiglas/ Perspex/ PMMA (Polymethyl methacrylate), is widely used in laser cutting due to its high durability, manufacturing efficiency, and ease of fabrication.

- Custom Acrylic cutting allows laser beams to curate masterpieces with high precision and complex designs

Acrylic laser cutting is a non-contact technique to create intricate designs with smooth cuts using low or high-powered CO2 laser beams. There are two most popular acrylic materials used in laser cutting:

- Cast Acrylic: It is Ideal for engravings, and can transform liquid acrylic into molds with smooth edges.

- Extruded Acrylic: Ideal material for cutting; presses acrylic sheets to the desired thickness.

Working of Acrylic laser cutting

To begin with, a digital design file (vector graphic, DXF, etc.) carrying a cutting path is created.

A CNC-operated, high-powered laser beam is focused on the tiny spot of acrylic sheet. The intense heat vapourises the sheet until the desired cut is obtained. For detailed engravings, the low-powered laser beams work only on the upper layer of the surface without cutting through the acrylic sheet.

Typically, laser cutting is preferred over CNC routing for thin to medium-thick acrylic sheets due to its ability to curate complex designs. Unlike CNC routers, this non-contact thermal process doesn’t require post-processing.

Confused between acrylic and metal laser cutting? Here are some key differences you need to know:

| Feature | Acrylic Laser Cutting | Metal Laser Cutting |

|---|---|---|

| Laser type | CO₂ | Fiber or CO₂ (depending on thickness) |

| Mechanism | Vaporization | Melt, burn & blow |

| Assist gas | Air | Oxygen |

| Laser speed | Fast | May vary for different metals |

| Thickness | 10 mm to 25 mm | 25 mm to 50 mm or more |

| Cost | Low machine cost & simple operation | High machine cost & complex operation |

Advantages of Acrylic Laser Cutting

As discussed in previous sections, acrylic laser cutting offers infinite potential to transform your business ideas into reality. Most of the new-age industries rely on this cost-effective process due to its simple operation. Unlike traditional cutting methods, acrylic laser cutting offers various benefits. Take a look!

1.High Precision & Smooth Edges: The instant vaporization effect by the CO2 laser results in smooth, clean & polished edges. It doesn’t require any secondary treatments.

2.Ideal for Complex Shapes & Designs: With a relatively fast speed compared to traditional cutting methods, acrylic laser cutting enables the easy production of complex designs.

3. No Tool Wear or Mechanical Contact: This non-contact cutting process eliminates the need for any mechanical tools or stress. Hence, there is no risk of material warping, chipping, or cracking.

4. Perfect for Transparent & Colored Acrylic Sheets: CO2 laser cuts produce a flame-polished look while maintaining the aesthetic properties of acrylic sheets.

Applications of Acrylic Laser Cutting in Pune

Many industries are leveraging the Acrylic laser cutting services in Pune due to their ability to meet high precision & quality demands. Here are some major applications of acrylic laser cutting services.

1. Signage & Display Boards: The Signage industry heavily relies on acrylic laser cutting services for creating clean cuts with a polished look. For instance, 3D Lettering, Logos, nameplates, branding elements, LED signboards, etc., are some masterpieces created using this cutting technique.

2.Architectural & Interior Designs: When it’s about creating designs with complex geometries, acrylic laser cutting is the preferred choice. It includes manufacturing decorative furniture, retail products, scaled models for real estate, and so on.

3.Prototyping & Custom Parts: Acrylic laser cutting services dominate non-metal applications. Customised protective panels, windows for industry machines, electronic enclosures, etc., are all manufactured using this advanced cutting process.

Besides this, laser-cut acrylic serves a range of industries relying on artwork and retail products. Corporate & event merchandise, hobby, craft & education, lighting and illumination sectors are some other key applications of acrylic laser cutting.

Choosing acrylic laser cutting in Pune is one of the best decisions for industries seeking high precision, quality, and rapid design iterations. The city provides a perfect blend of robust technology and accessibility of resources for both low and high-volume productions. Here are the solid reasons to choose Pune for your upcoming acrylic laser cutting project:

- Access to skilled operators & latest equipment

- Fast turnaround for prototypes and bulk jobs

- Affordable local pricing compared to metros

- Strong manufacturing ecosystem

- Logistical & time advantages

FAQs on Acrylic laser cutting

1.What thickness of acrylic can be laser cut?

Laser beams with a 2-inch lens can cut an acrylic sheet of up to 10mm thickness. However, a 4-inch lens is required to cut acrylic sheets of 15-20mm thickness.

2.Does laser cutting cause yellow edges on acrylic?

Yes, laser cutting can cause discoloration, especially on light-colored acrylic sheets, due to thermal distortion. It can be prevented by increasing cutting speed, optimising gas assist, focus, and frequency.

3.Is acrylic laser cutting suitable for mass production?

Yes, it is highly efficient for large volume production with high precision, intricate designs, and clean cuts.

4.What file formats are needed for cutting designs?

File formats depend on the type of cutting machine and the type of cuts, such as 2D, 3D, or engraving. Generally, the vector file format is used for 2D cutting, and AutoCAD for 3D cuts.

5.How is the cost of acrylic laser cutting calculated?

Machine time is the key factor used to calculate the cost of acrylic laser cutting. Rest material, setup, labour, order volume, and additional services also add to the overall cost. In short,

Total Cost=(Machine Time Rate×Minutes)+Material Cost+Setup Fee+Finishing/Labor Costs+Profit Margin

Best Laser cutting services by Cyclotron Industries. We offer high precision, fast and accurate laser cutting solutions for any kind of metal applications

Laser cutting services

Laser cutting services in Pune

Fiber laser cutting services in Pune

Metal laser cutting services in Pune

Laser cutting for sheet metal parts

CNC Laser cutting services in Pune