Laser cutting cost

Laser cutting cost in India

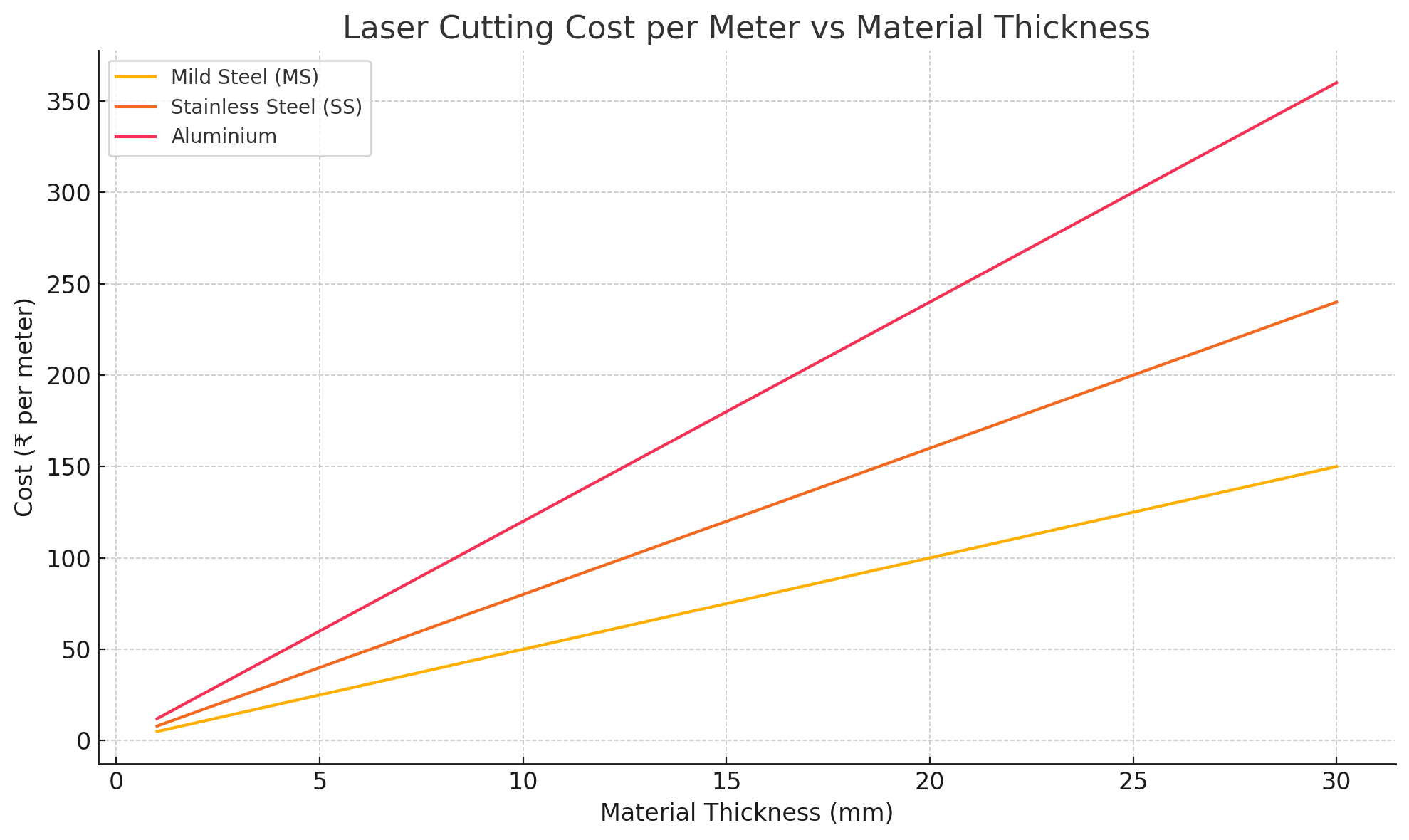

Laser cutting cost in India is Rs 5-10 per meter per mm, It will cost Rs 5-10/meter for 1 mm material. Similarly will cost Rs 10-20/meter for 2 mm material.

- Worried your laser-cutting quotes are inconsistent or confusing?

- You’re not alone — many small manufacturers face similar headaches when comparing vendors.

- Understanding the cost of laser cutting is crucial for manufacturers, hobbyists, and businesses involved in material processing.

- Calculating these costs accurately can improve your project’s budget management and efficiency.

- This blog post offers a brief overview of laser cutting cost, detailing the actual expenses associated with laser cutting . It includes a comparison table of laser cutting prices in India and discusses key factors that influence the costs of laser cutting.

Best Laser cutting services by Cyclotron Industries. We offer high precision, fast and accurate laser cutting solutions for any kind of metal applications

Laser Cutting Cost per meter

- Laser cutting cost per meter is Rs 5-10 for 1mm thick material and increases lineraly with the thickness of the material.

- Laser cutting costs in India depend on the material used, its thickness, the type of machine (fiber or CO₂), and the level of detail required for the job.

- Small orders usually cost more per piece, while bigger orders bring down the price. Additional charges may apply for design setup, finishing, or delivery. Obtaining quotes from various vendors and clearly specifying the material can help save money and prevent confusion.

Factors That Affect Laser Cutting Cost

Understanding the key factors that drive laser cutting costs is essential for making informed decisions and optimizing your budget effectively.

- Material Type and Thickness: Material type and thickness are crucial in determining laser cutting costs. Different materials, such as metals, plastics, and wood, require varying levels of laser power, which affects the operational costs. For example, cutting thicker metals, such as steel or aluminium, requires more power and advanced laser systems, resulting in higher expenses.

- Design Complexity and Setup: The intricacy of a design greatly influences both preparation and execution costs in laser cutting. Complex patterns with detailed features require more programming and setup time, resulting in increased overall costs.

- Cutting speed and batch size: Cutting speed and batch size have an essential impact on the cost of laser cutting. Faster cutting saves time but may require stronger, more machines, which can increase the price. Small batches cost more per piece, while larger orders reduce the unit cost, making bulk production more budget friendly.

Best Laser cutting services by Cyclotron Industries. We offer high precision, fast and accurate laser cutting solutions for any kind of metal applications

Laser cutting cost per mm in India

| Thickness (mm) | MS (₹/mtr) | SS (₹/mtr) | Aluminium (₹/mtr) |

|---|---|---|---|

| 1 | 5 | 8 | 12 |

| 2 | 10 | 16 | 24 |

| 3 | 15 | 24 | 36 |

| 4 | 20 | 32 | 48 |

| 5 | 25 | 40 | 60 |

| 6 | 30 | 48 | 72 |

| 7 | 35 | 56 | 84 |

| 8 | 40 | 64 | 96 |

| 9 | 45 | 72 | 108 |

| 10 | 50 | 80 | 120 |

| 11 | 55 | 88 | 132 |

| 12 | 60 | 96 | 144 |

| 13 | 65 | 104 | 156 |

| 14 | 70 | 112 | 168 |

| 15 | 75 | 120 | 180 |

| 16 | 80 | 128 | 192 |

| 17 | 85 | 136 | 204 |

| 18 | 90 | 144 | 216 |

| 19 | 95 | 152 | 228 |

| 20 | 100 | 160 | 240 |

| 21 | 105 | 168 | 252 |

| 22 | 110 | 176 | 264 |

| 23 | 115 | 184 | 276 |

| 24 | 120 | 192 | 288 |

| 25 | 125 | 200 | 300 |

| 26 | 130 | 208 | 312 |

| 27 | 135 | 216 | 324 |

| 28 | 140 | 224 | 336 |

| 29 | 145 | 232 | 348 |

| 30 | 150 | 240 | 360 |

Note: The prices mentioned above are based on our practical experience and average market trends observed across various laser cutting service providers in India. Actual pricing may vary depending on your specific material grade, thickness tolerance, job complexity, and order quantity. We recommend verifying the cost with your local service provider or requesting a customized quotation for the most accurate and project-specific pricing.

Laser cutting piercing cost in India Chart

| Thickness (mm) | MS (₹/pierce) | SS (₹/pierce) | Aluminium (₹/pierce) |

|---|---|---|---|

| 1 | 0.5 | 0.8 | 1 |

| 2 | 1 | 1.6 | 2 |

| 3 | 1.5 | 2.4 | 3 |

| 4 | 2 | 3.2 | 4 |

| 5 | 2.5 | 4 | 5 |

| 6 | 3 | 4.8 | 6 |

| 7 | 3.5 | 5.6 | 7 |

| 8 | 4 | 6.4 | 8 |

| 9 | 4.5 | 7.2 | 9 |

| 10 | 5 | 8 | 10 |

| 11 | 5.5 | 8.8 | 11 |

| 12 | 6 | 9.6 | 12 |

| 13 | 6.5 | 10.4 | 13 |

| 14 | 7 | 11.2 | 14 |

| 15 | 7.5 | 12 | 15 |

| 16 | 8 | 12.8 | 16 |

| 17 | 8.5 | 13.6 | 17 |

| 18 | 9 | 14.4 | 18 |

| 19 | 9.5 | 15.2 | 19 |

| 20 | 10 | 16 | 20 |

| 21 | 10.5 | 16.8 | 21 |

| 22 | 11 | 17.6 | 22 |

| 23 | 11.5 | 18.4 | 23 |

| 24 | 12 | 19.2 | 24 |

| 25 | 12.5 | 20 | 25 |

| 26 | 13 | 20.8 | 26 |

| 27 | 13.5 | 21.6 | 27 |

| 28 | 14 | 22.4 | 28 |

| 29 | 14.5 | 23.2 | 29 |

| 30 | 15 | 24 | 30 |

Note: The prices mentioned above are based on our practical experience and average market trends observed across various laser cutting service providers in India. Actual pricing may vary depending on your specific material grade, thickness tolerance, job complexity, and order quantity. We recommend verifying the cost with your local service provider or requesting a customized quotation for the most accurate and project-specific pricing.

Why Choose Cyclotron for Affordable Laser Cutting Services

Investing in Cyclotron is the right move because we’re not a middleman or bulk outsourcing agency. We manufacture ourselves with over 30 years of expertise in fabrication and machining, which sets us apart from our competitors.

Transparent pricing model: Our transparent pricing model gives clear, itemized quotes with no hidden fees. Clients receive precise estimates based on material, cutting time, and finish requirements, allowing for predictable budgets and informed decision-making. We explain cost drivers, offer competitive rate options, and adjust proposals to fit priorities without surprise charges or ambiguous terms.

Advanced CNC fiber laser machines: Cyclotron uses advanced CNC fiber laser machines that deliver faster, cleaner cuts with superior precision. Higher energy efficiency reduces power consumption and material waste, lowering per-part costs. Combined with automated nesting and optimized toolpaths, our technology shortens lead times, improves repeatability, and passes efficiency savings directly to customers every time.

Custom solutions for small and large batches: We create custom workflows for both single prototypes and high-volume production runs, optimizing setup, nesting, and finishing for scale. Our flexible scheduling and batch-pricing strategies make small orders economical. This adaptability offers consistent quality, predictable costs, and on-time delivery across every project.

Best Laser cutting services by Cyclotron Industries. We offer high precision, fast and accurate laser cutting solutions for any kind of metal applications

Laser cutting services

Laser cutting services in Pune

Fiber laser cutting services in Pune

Metal laser cutting services in Pune

Laser cutting for sheet metal parts

CNC Laser cutting services in Pune