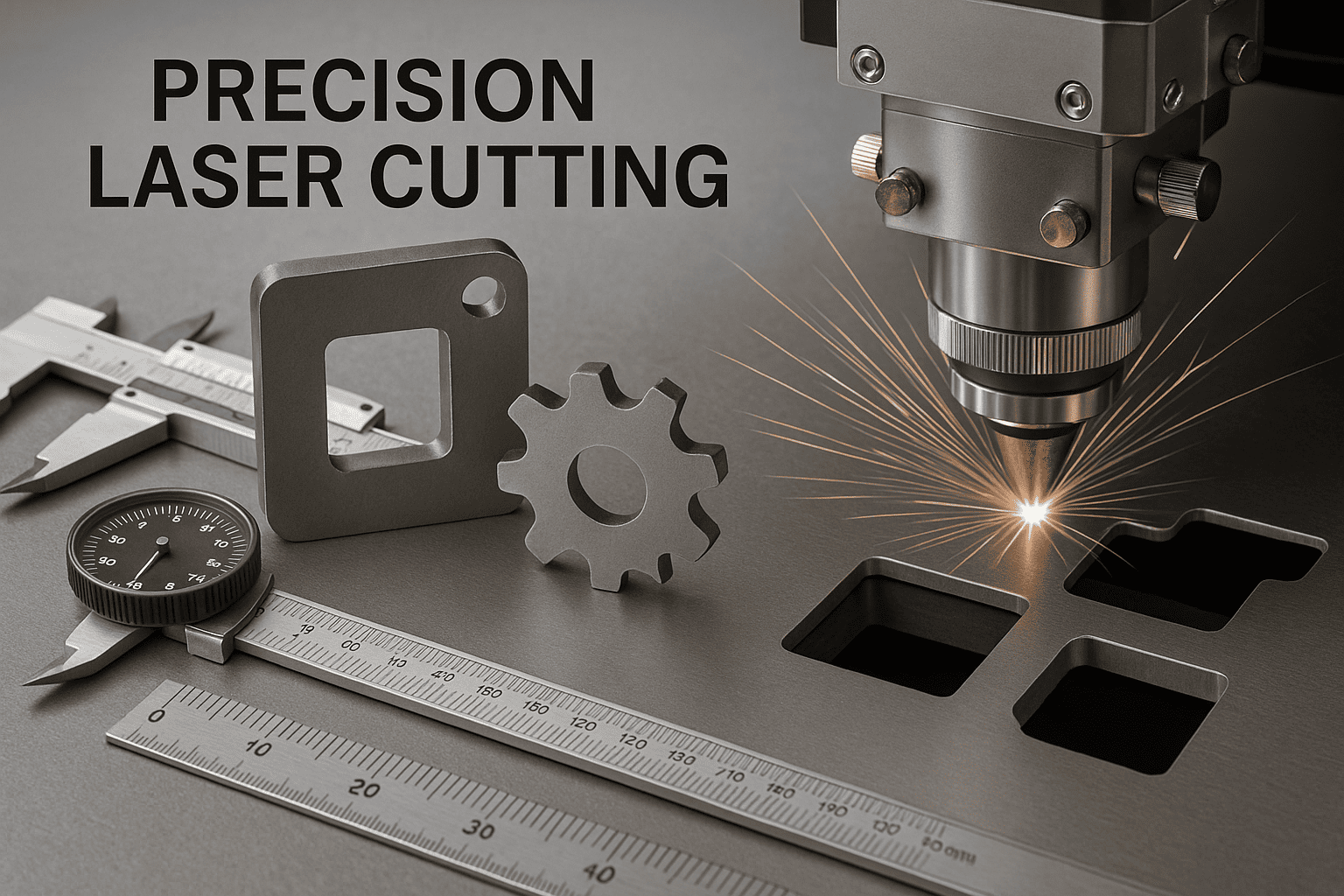

Precision laser cutting

Precision laser cutting - Tolerances & Best Practices

Precision Laser cutting is not merely a technology upgrade but a paradigm shift in traditional metal fabrication. This advanced technology focuses on achieving high edge quality and extremely tight tolerances for different metals. Read this blog to learn about the importance of laser tolerance in achieving clean cuts and burr-free edges. Additionally, discover how laser cutting services in Pune are implementing best practices to achieve micro-precision.

Introduction to Precision Laser Cutting

When seeking Precision laser cutting practices, it’s crucial to focus on technical details. Precision, accuracy, and edge quality are some critical parameters in laser cutting operations

- However, to achieve precision and meet strict quality standards, it is quintessential to know in detail about the material type and laser tolerance (small deviation from actual dimensions).

Let’s read this guide to understand how the laser cutting tolerance level impacts the precision & quality of laser-cut metal components.

Best Laser cutting services by Cyclotron Industries. We offer high precision, fast and accurate laser cutting solutions for any kind of metal applications

Understanding Tolerances in Laser Cutting

- Tolerance in metal fabrication states the permissible or acceptable deviation from the specified dimensions of the cut piece. It's the tolerance level that ensures the designed & manufactured metal part is of high precision and quality. It can be either positively or negatively influenced by various factors, including:

- Material type & thickness, Machine Calibration, Assembly & fabrication operation, Design & Geometry, Environmental & human factors

- Precise tolerance means the product is of high quality and matches the performance parameters. Whereas, poor tolerance indicates a high risk of material warping, HAZ (heat-affected zone), and an inability to meet safety & quality standards. Fiber laser cutting in Pune, known for its high precision, can achieve extremely tight tolerances of up to ±0.05mm for fragile metals.

Edge Quality in Laser Cutting

Good edge quality refers to uniform or smooth edges with minimal HAZ and material warping. Getting smooth and burr-free edges in laser cutting requires optimal selection of material, cutting parameters, assist gas, power, focus adjustment, and various other factors. Below is a comparison of edge quality between different cutting techniques.

| Feature | Laser Cutting | Plasma | Waterjet |

|---|---|---|---|

| Edge Quality | Smooth edges for thin to medium materials. | Visibly rough edges, requires secondary treatment. | Burr-free edges irrespective of material thickness. |

| Burr / Dross | Minimal burrs can be easily managed with optimised parameters. | Noticeable slags, expensive grinding / scrapping. | Residual grit or feather edges can be easily wiped off. |

| HAZ (Heat-Affected Zone) | Minimal. | High. | None. |

| Taper (Perpendicularity) | High precision (near-zero taper) on thin to medium metal sheets. | Unavoidable, huge difference between top & bottom cuts. | Near-zero taper using multi-axis head & slow cutting speed. |

Best Laser cutting services by Cyclotron Industries. We offer high precision, fast and accurate laser cutting solutions for any kind of metal applications

Best Practices for Laser Cutting

So, what helps achieve precise cuts, smooth edges with tight tolerances? Buying the best cutting machine is not the solution; the laser cutting process requires a holistic approach. Take a look!

- Material preparation: Ensure surface cleanliness, along with effective clamping and support, to streamline the entire cutting process. It is recommended to adopt the nesting techniques (program the cutting path) to minimise waste and maintain accuracy.

- Proper CAD/CAM design: Precision laser cutting requires a proper design in CAD (Computer-Aided Design) & CAM (Computer-Aided Manufacturing) software. The laser path & kerf-width must be clearly defined to avoid any disruptions in the manufacturing process.

- Selecting the right assist gas: Use high-purity assist gases (oxygen, nitrogen, air) in adequate amounts & pressure to achieve burr-free edges with perfect kerf width.

- Optimising cutting parameters: Ensure that all cutting & performance parameters (speed, power, focal position, calibration, frequency, etc.) are finely tuned to avoid any deviation from the specified dimensions.

Common Challenges in Precision Laser Cutting

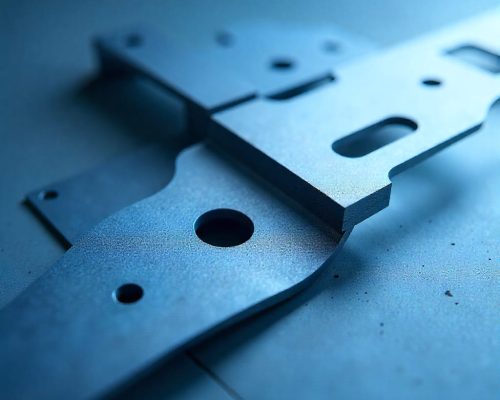

Precision laser cutting services provide precise results for thin metals, including stainless steel and carbon steel. However, maintaining tolerances on thick metals is quite challenging. The high-powered laser beam focuses on a very small spot, leading to high heat-affected zones (HAZ), rough edges, and material damage during manufacturing. Check below some common challenges arising in laser cutting:

- Burr formation: Edge Irregularity is one of the most common challenges encountered when ejecting metal parts from thick sheets. Implementing advanced techniques, such as pulsed laser cutting or cooling systems, can lower the risk of burr formation.

- Material inconsistency: Due to the varying properties & composition of thick metals, it is likely to deviate from the given tolerances. The solution is to use adaptive control systems to adjust cutting parameters.

- Cutting reflective materials: Metals like aluminium, copper, etc. have high thermal & electrical conductivity, which sometimes makes the laser cutting process volatile.

Applications That Require High Precision & Edge Quality

In high-stakes sectors like aerospace and automotive, precision and edge quality are non-negotiable. With the capability to provide unmatched precision, safety, and functionality, laser cutting has already become a preferred process for cutting metal components. Here are some key applications of precision laser cutting.

- Aerospace & defence parts: CNC-operated fibre laser ensures that the created metal parts(turbine blades, airframe shims, armoured vehicles, engine gaskets, etc.) are highly durable and can withstand extreme conditions.

- Medical devices: The cutting-edge technology enables the creation of a wide range of intricate medical devices, including stents, catheters, implants, diagnostic equipment, and sensors.

- Electronics & enclosures: Precision laser cutting benefits this industry with minimal HAZ and thermal stress. PCBs, FPCs, connectors, micro-components & housings are all key applications of laser cutting.

- Industrial machinery parts: Industrial machinery parts are crucial components in various types of heavy equipment and automation systems. This specialized sector significantly depends on advanced laser cutting services to precisely fabricate these parts. Laser cutting enables the creation of intricate designs while ensuring burr-free edges and maintaining tight tolerances, which are crucial for the optimal functioning and longevity of the machinery.

Why Choose Cyclotron for Precision Laser Cutting Services

Laser cutting is a complex process that requires careful planning, design, and selection of the appropriate parameters. With experience across high-precision industries and proven expertise in edge quality & complex geometries, Cyclotron promises to deliver super-precise cuts. We offer top-notch laser cutting services in Pune to meet your industry-specific precision needs. Here are the solid reasons to hire Cyclotron.

- Advanced equipment with high precision & stability

- Rapid prototyping & production

- Custom part dimensions

- Quick turnaround

- Dedicated customer support

Conclusion

If you want to set up a fabrication business in India, understanding fabrication work HSN code is essential. Accurate HSN classification ensures GST compliance, makes accounting a bit simpler, and helps businesses claim input tax credit properly. Be it MS fabrication, SS fabrication, or just steel fabrication in general, using the right HSN code usually helps standardize taxation, cut down errors, and keeps operations running smooth without interruptions.

With the latest 2025 update, most fabrication work falls under the 18% GST rate, so it is important for businesses to keep an eye on HSN code changes. Following these codes properly helps companies stay compliant, makes operations easier, and lets them focus more on growth in the metal fabrication industry.

Best Laser cutting services by Cyclotron Industries. We offer high precision, fast and accurate laser cutting solutions for any kind of metal applications

Laser cutting services

Laser cutting services in Pune

Fiber laser cutting services in Pune

Metal laser cutting services in Pune

Laser cutting for sheet metal parts

CNC Laser cutting services in Pune