Laser cutting for Aerospace components

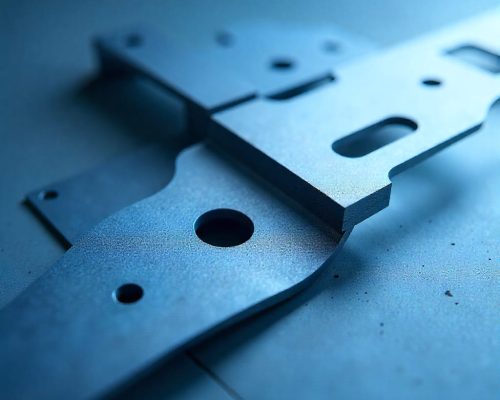

Laser cutting for aerospace components

In aerospace, there’s no room for mistakes. Parts like turbine blades and fuselage panels must fit and work perfectly, because lives and big missions depend on them. That’s why laser cutting has become so important, and it helps make parts exactly right, every time.

Think of modern fiber lasers as an exact pair of scissors on fast-forward. They cut tiny, complicated shapes quickly and with extreme accuracy. That means manufacturers can produce parts that meet strict safety standards, waste less material, and spend less time on fixing or reworking pieces.

- This blog post covers everything you need to know about laser cutting for aerospace industry, including its advantages, challenges, and more.

Best Laser cutting services by Cyclotron Industries. We offer high precision, fast and accurate laser cutting solutions for any kind of metal applications

Introduction to Laser Cutting in Aerospace Industry

- Laser cutting uses a focused light beam to accurately cut metals and composite materials, making it suitable for use in aircraft and spacecraft.

- This technique enables the creation of intricate shapes with high precision and accuracy. Additionally, it minimizes the waste and eliminates the need for extra machining steps.

- Aerospace manufacturers must rely on laser cutting to produce lightweight yet robust components that meet stringent safety and tolerance standards.

Precision is the backbone of aerospace manufacturing. Here is why precision plays a strategic role in aerospace manufacturing:

Safety-critical components

These are parts whose failure could cause accidents, such as turbine blades, landing-gear parts, control surfaces, and fasteners. Because human lives depend on them, every feature, hole, edge, and joint must be made exactly as designed. Even a small flaw (a crack, burr, or wrong hole) can grow under stress and lead to catastrophic failure.

Precision reduces the chance of hidden defects, lowers inspection time, and means parts behave predictably during flight.Lightweight but strong materials

Aerospace designs aim to be as lightweight as possible to conserve fuel and increase payload while maintaining extreme strength. That’s why engineers use materials like titanium, carbon-fibre composites, and advanced aluminium alloys.

- Laser cutting is a powerful tool for making parts used in airplanes and spacecraft.

- It helps engineers and factories make strong, safe parts that must meet very high standards. Because lasers cut by focusing light, they can make immaculate, exact cuts without touching the material. That makes them perfect for many aerospace jobs.

- Cutting thin and thick aerospace alloys

Lasers work well on both thin and thick metal sheets. For thin metals, the cut is smooth and precise and there’s little bending or damage. For thicker alloys, modern lasers can cut deeply with steady power, ensuring parts remain strong. Whether it’s a thin bracket or a thick structural plate, laser cutting gives predictable results. That means fewer trial-and-error and less wasted metal. - Complex geometries & intricate designs

One big advantage of laser cutting is the ability to make complex shapes. Need tiny holes, tight curves, or a part with many small features? - Lasers can do that with high accuracy.

- Faster prototyping & production cycles

Lasers enable a quicker transition from an idea to a real part. Designers send digital files straight to the laser machine — no molds or special tools needed. That makes prototypes fast and less costly. When a design is finalized, production can scale up quickly because the same machines repeat cuts with the same accuracy. Faster cycles enable engineers to test more ideas and deliver better parts to service sooner.

Best Laser cutting services by Cyclotron Industries. We offer high precision, fast and accurate laser cutting solutions for any kind of metal applications

Advantages of Laser Cutting for Aerospace Parts

Here are some key benefits of using laser cutting for aerospace parts:

1.High precision & accuracy

One of the key advantages of using laser cutting for aerospace part fabrication is its ability to deliver high precision and accuracy. Lasers can be focused to a minimal spot size, enabling precise cuts with tolerances as low as a few micrometres. This level of precision is vital in the aerospace industry, where even the slightest deviation from design specifications can have serious consequences.

2. Ability to cut exotic materials (titanium, aluminium, stainless steel)

Lasers can cut through tough and specialized materials, such as titanium, Inconel, aluminium, and stainless steel, which are often used in aerospace applications. Traditional tools struggle with these types of metals. Laser cutting makes shaping these materials easier and faster. Engineers can work with advanced materials without compromising quality or strength.

3. Minimal heat distortion

Laser cutting produces very little heat in the surrounding material. This reduces the risk of warping or deforming the parts. Maintaining the original shape and strength of aerospace components is essential. Minimal heat distortion ensures parts remain true to design and function perfectly in extreme conditions.

4. Flexibility for both small and large batch production

Laser cutting is well-suited for producing a few custom parts or thousands of identical pieces. This flexibility enables the aerospace manufacturers to respond to varying project sizes and requirements. Companies can produce prototypes quickly and then scale up to full production without needing to change machines or tools. It saves time and money.

Here is the table that demonstrates the difference between laser cutting for aerospace vs and conventional cutting for aerospace

| Feature | Laser Cutting | Conventional Cutting |

|---|---|---|

| Precision & Accuracy | Extremely high, tolerances in micrometres, ideal for complex designs | Moderate, harder to achieve very tight tolerances |

| Material Capability | Can cut exotic materials like titanium, Inconel, aluminium, stainless steel | Limited; some hard or advanced alloys are difficult to cut |

| Heat Distortion | Minimal, reduces warping or material stress | Higher, can cause warping, especially in thin or delicate parts |

| Edge Quality | Smooth, clean edges, minimal finishing required | Rough edges, often require additional grinding or finishing |

| Production Flexibility | Suitable for small batches, prototypes, and large-scale production | Best for standard shapes and large volumes; less flexible for custom designs |

| Speed | Fast for complex or precise cuts | Slower for complex shapes, faster for simple straight cuts |

| Tool Wear & Maintenance | Minimal tool wear since no physical contact | High wear and frequent tool replacement needed |

| Cost Efficiency | More cost-effective for complex designs and precision parts | Cheaper for simple, high-volume cuts but less efficient for complex designs |

We are direct manufacturers, not the middlemen. Our experienced team understands the complexities of cutting, enabling us to provide high-quality space laser cutting services with ease. Here are some reasons to choose Cyclotron for your aerospace laser cutting needs:

Advanced CNC Fiber Laser Machines

We utilize the state-of-the-art CNC fiber laser machines that can handle intricate designs with exceptional accuracy. These machines enable us to cut complex shapes, reduce lead times, and maintain consistent quality across both small and large production batches for aerospace projects.

Expertise with Aerospace Alloys & Standards

Cyclotron specializes in working with challenging aerospace materials, including titanium, Inconel, aluminium, and stainless steel. Our expert engineers are fully aware of the aerospace industry’s standards and quality requirements, ensuring that every part meets stringent specifications and performs exceptionally well in demanding conditions.

Can laser cutting handle aerospace-grade titanium?

Yes — laser cutting can process aerospace-grade titanium (e.g., Ti-6Al-4V). With high-power fiber or CO₂ lasers, inert shielding gas, and precise parameter control, you get accurate, repeatable cuts. Watch for heat-affected zones and oxidation; critical aerospace parts also typically require careful fixturing, post-processing, and surface finishing to meet certification standards.

Is laser cutting cost-effective for aerospace prototyping?

Overall, laser cutting is a cost-effective option for prototyping in the aerospace industry. It reduces the material waste, offers high precision, and accelerates production. It’s ideal for testing designs quickly without the need for expensive tooling

What standards are followed in aerospace laser cutting?

Aerospace laser cutting adheres to rigorous standards, including AS9100, ISO 9001, and NADCAP. These ensure safety, accuracy, and quality, covering everything from material handling to cutting, inspection, and final certification.

Best Laser cutting services by Cyclotron Industries. We offer high precision, fast and accurate laser cutting solutions for any kind of metal applications

Laser cutting services

Laser cutting services in Pune

Fiber laser cutting services in Pune

Metal laser cutting services in Pune

Laser cutting for sheet metal parts

CNC Laser cutting services in Pune