Metal laser cutting in Pune

Metal laser cutting in Pune

Metal laser cutting has become quite an indispensable service in Pune due to its ability to meet high precision and quality standards. The innovative technology has brought an enormous revolution, especially in the manufacturing and metal fabrication sectors.

We recommend reading this detailed guide to gain a better understanding of the metal laser cutting process and make a more informed decision about metal laser cutting in Pune.

The integration of the CNC system with traditional metal cutting techniques has shifted the paradigm to a fully automated workflow.

Modern laser cutters have simplified the process of creating intricate designs and patterns using high-beam lasers.

Best Laser cutting services by Cyclotron Industries. We offer high precision, fast and accurate laser cutting solutions for any kind of metal applications

Introduction to Metal Laser Cutting in Pune

- Serving a wide array of industries, including the automobile, aerospace, and construction sectors, Metal Laser Cutting in Pune has become crucial due to its high precision and efficiency.

- If you are seeking state-of-the-art Metal laser cutting services in Pune, you have already opened a vast pool of capabilities and technologies. With innovative technology & a supportive ecosystem, Manufacturers in Pune promise to deliver high-precision laser cutting for metal parts.

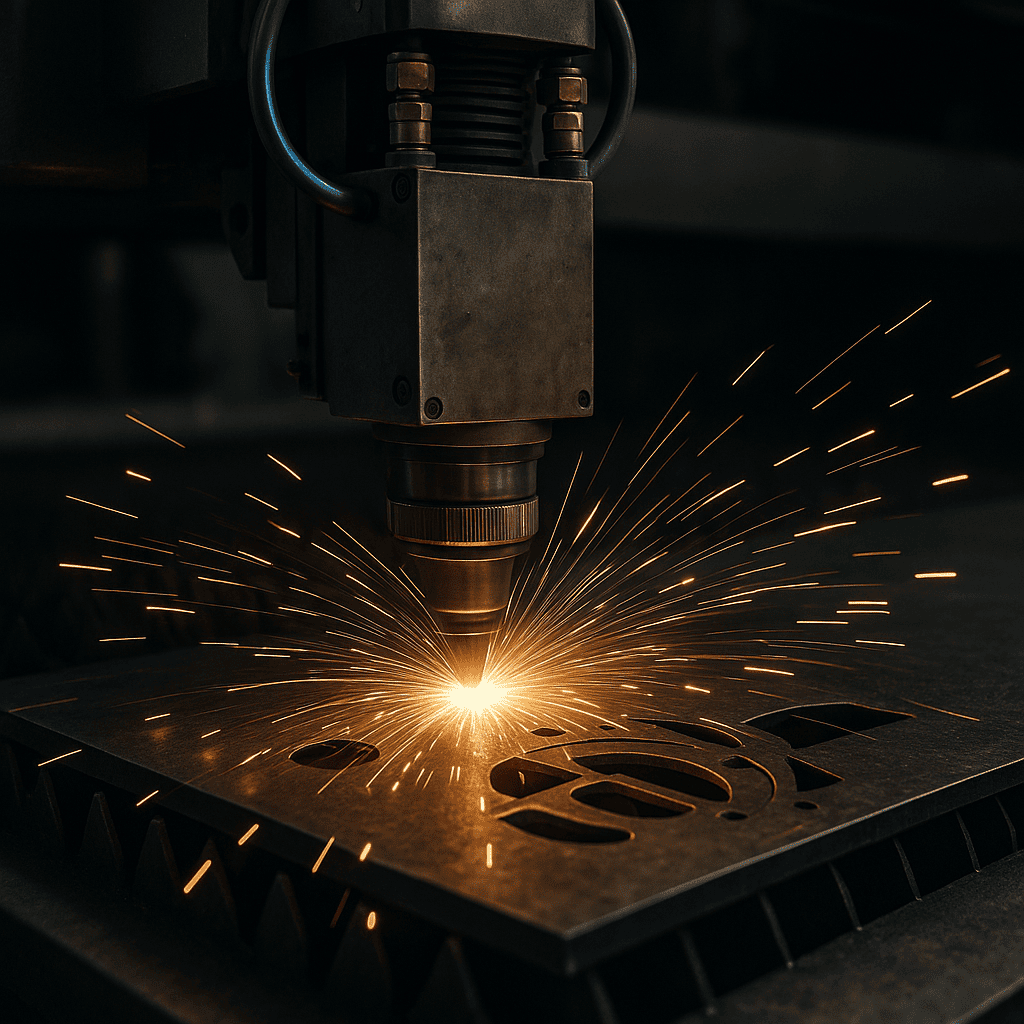

It’s a non-contact, automated, and advanced manufacturing process that uses high-powered laser beams to cut different types of metal sheets into intricate designs. Controlled by CNC (Computer Numerical Control )machines, a laser beam is generated using either fiber or CO2 lasers.

The laser beam, emitting intense heat, is then focused onto the metal surface, which melts, vaporizes, and burns the metal to the desired shape. Finally, an assist gas (Oxygen/Nitrogen) is released to blow away the waste material and create clean cuts.Unlike traditional cutting methods (such as shearing, punching, and sawing), the metal laser cutting process is pre-programmed and doesn’t require any physical contact. Metal Laser cutting offers several benefits, including.

- High-precision & Accuracy

- Smooth edges with burr-free cutting

- Versatility to cut a wide range of metals of different thicknesses

- Maximum material utilization & minimal waste.

- Quick production times with high speed and efficiency

Advantages of Metal Laser Cutting

As already discussed, high-tech Metal laser cutting eliminates the need for physical contact, unlike traditional cutting methods. CNC-controlled Metal laser cutting machines follow a pre-programmed path that enhances the speed, accuracy, and quality. Below are some key benefits of metal laser cutting. Take a look!

High precision & accuracy: High precision is the primary catalyst for industries like aerospace and automotive. Instead of using mechanical cutting tools, metal laser cutting uses a sharp laser beam to cut the metal sheet into complex designs of

Faster cutting speeds: Metal Laser cutting machines are known for their high speed and efficiency; the entire cutting process is automated and controlled by the CNC system.

Clean edges & reduced finishing work: The focused laser beams melt, vaporise, and burn the metal sheet into specific shapes. The ultimate finesse eliminates the need for additional processes, such as grinding and deburring.

Versatility: The ability to cut through various metals (steel, aluminium, mild steel, stainless, etc.) makes metal laser cutting machines an ideal choice among multiple industries.

Cost-effectiveness: The metal laser cutting process doesn’t require physical contact, which reduces maintenance costs and tool wear damage. Moreover, it works with digital design, ensuring consistency in cut quality for both small and large production units.

Metal laser cutting in Pune is in high demand and is already serving a diverse range of industries, including.

1.Automotive & transport

It’s one of the largest sectors that relies on laser cutting for metal parts due to its high precision. It involves cutting body panels, engine parts, transmission components, and other functional components from various metals.

2. Aerospace & defence

Both industries rely on laser cutting to produce metal components with extremely tight tolerances, for example, cutting parts for weapon systems, military equipment, flight control systems, and fuselage frames, among others.

3. Construction & fabrication

Metal laser cutting enables the creation of aesthetic and customized designs, such as railings, jali, fencing, and light fixtures, in modern architecture.

4. Signage & decorative products

Laser cutting for metal parts has revolutionized the signage sector by enabling the creation of customized metal signage logos, artistic installations, laser-cut letters, and more.

Cyclotron is among the leading suppliers of Metal laser cutting services in Pune, serving diverse industries with custom solutions. Speed and accuracy are two prominent factors that determine the quality of metal laser cutting. With our experience and expertise in precision metal cutting, we promise to deliver clean, laser-cut parts with unmatched precision and minimal waste. Here’s why us?

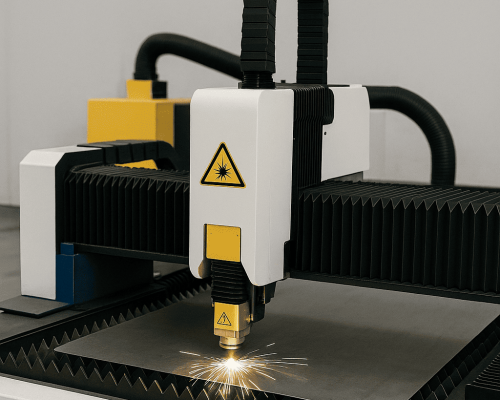

Advanced CNC fibre laser machines

- High-power laser solutions for a wide range of metals (aluminium/titanium/carbon steel, etc.),

- Burr-free cutting with optimum material utilisation.

- Capability to handle a cutting thickness range from 0.5 to 50mm

- Comprehensive Support (installation, maintenance, training, etc.)

- Competitive prices

Best Laser cutting services by Cyclotron Industries. We offer high precision, fast and accurate laser cutting solutions for any kind of metal applications

Laser cutting services

Laser cutting services in Pune

Fiber laser cutting services in Pune

Metal laser cutting services in Pune

Laser cutting for sheet metal parts

CNC Laser cutting services in Pune