Ai for improving laser cutting

Ai for improving laser cutting

The future of metal cutting thinks, adjusts, and never sleeps.

AI, IoT, and smart-factory thinking are transforming laser cutting from a manual trade into a continuously learning manufacturing system.

Modern fiber-laser machines now pair sensor arrays and edge computers with cloud dashboards, letting shops tune cut parameters in real time, detect defects instantly, and run unattended through nights and weekends. That shift doesn’t just speed the production; moreover, it cuts scrap, slashes energy costs compared with legacy CO₂ setups, and opens the door to predictive maintenance that keeps lines alive. For fabricators, the question is no longer whether to adopt Industry 4.0, but how fast they can retrofit existing floors, pilot adaptive cutting, and scale automation with confidence.

This post briefly discusses how AI plays a role in laser cutting, focusing on ‘smart factory laser cutting’ and ‘IoT manufacturing laser trends

Best Laser cutting services by Cyclotron Industries. We offer high precision, fast and accurate laser cutting solutions for any kind of metal applications

The Evolution of Laser Cutting: From CO₂ to Fiber Lasers

- Laser cutting has seen significant technological advancements over the past few decades. Older CO₂ laser systems, while effective, often required manual adjustments and did not have the capacity to optimize cutting parameters in real time. They also had limitations in terms of energy efficiency, maintenance, and flexibility.

- Enter fiber laser technology, which offers greater precision, faster cutting speeds, and higher energy efficiency. With the integration of AI-driven optimization and IoT monitoring, modern fiber-laser systems are far superior to older CO₂ systems, enabling manufacturers to achieve faster production times, higher-quality cuts, and reduced material waste.

- This shift towards fiber lasers with Industry 4.0 integration is ushering in a new era of intelligent, automated, and more sustainable manufacturing processes.

Most of the next-generation laser cutting machines are integrated with CNC systems for autonomous & AI-driven operations. Whether you are hiring a laser service provider or entering the laser manufacturing world, it’s beneficial to have a deep understanding of various laser cutting techniques.

| Feature | CO₂ Laser Cutting Machines | Fiber Laser Cutting Machines |

|---|---|---|

| Energy Source | Mix of gases such as CO₂, helium, and nitrogen. | Optical fibers with rare earth elements like ytterbium. |

| Laser Wavelength | 10.6 µm (infrared rays). | 1.06 µm (easily absorbed by metals). |

| Best for Materials | Non-metals (wood, plastic, acrylics, fabric, glass, stone). | Metals (aluminium, steel, copper, brass) with high precision. |

| Applications | Textiles, architectural models, craftwork, displays, etc. | Metal fabrication, electronics, medical devices, aerospace & automotives. |

| Pros | Low initial cost and excellent results for non-metallic products. | Low maintenance, high energy efficiency, and cutting speed. |

| Cons | High operating cost and struggles with reflective materials. | High initial cost. |

Best Laser cutting services by Cyclotron Industries. We offer high precision, fast and accurate laser cutting solutions for any kind of metal applications

How to Choose the Right Laser Cutting for Your Business?

It is essential to make an informed decision when investing in a modern laser cutting machine for your new or existing business. After all, the success, sustainability, and scalability of your venture depend a lot on your choice. So, what you need to do is:

- Define your business needs & goals: know the material & thickness range

- understand different types of Laser cutting machines

- Know the laser power & thickness capability

- Check for smart AI features & Industry 4.0 integrations

- Compatibility with software (CAD, CorelDRAW, FSCUT, Ruida, etc.)

- Compare operation cost & maintenance

- Choose a reputed & reliable manufacturer

- Choose the vendor that offers technical support and availability of spare parts.

Last but not least, make sure to do the cost analysis of your laser cutting machines, as the prices may vary across different cities.

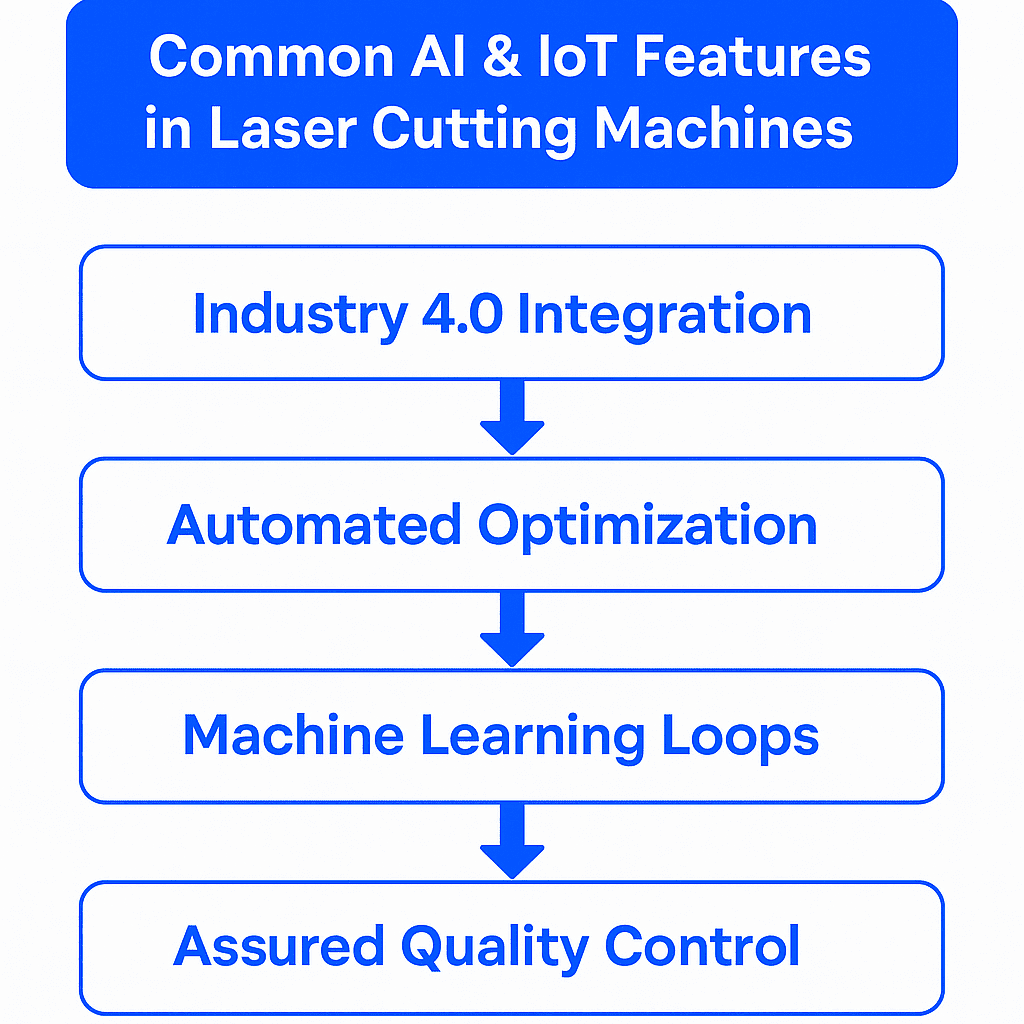

The present laser cutting machine not only cuts with accuracy but also saves energy and automatically corrects any issues. All thanks to AI & IoT! Here are some key AI & IoT features that you should look for while evaluating laser cutting services:

Industry 4.0 Integration:

The seamless integration of Cyber-Physical Systems (CPS), ERP, MES (Manufacturing Execution Systems), IIoT (Industrial Internet of Things), robotics, etc., in laser cutting has digitised all aspects of the industrial ecosystem.

Automated Optimisation:

AI technology has enabled laser cutters to automatically optimize their power, energy, focus, and intensity settings depending on the material.

Machine Learn Loops:

These advanced laser machines have been built with the feature to learn and enhance their performance from every cut.

Assured Quality Control:

The AI-driven laser cutters can easily detect defects with the help of built-in AI sensors and cameras.

Future Trends & Technology Advancements in Laser Cutting

It’s the high demand for precision that has led to upgrades in laser manufacturing. AI & IoT have helped laser manufacturing expand its capability, efficiency, and sustainability. Below are some key future trends to look out for in laser cutting technology:

- Autonomous Integration has eliminated the need for manual laser cutting operations.

- Real-time interaction with laser machines using Augmented Reality (AR) Integration.

- Implementation of Blockchain technology for laser Data Security.

- Fibre laser cutting technology is used for reflective materials like copper, brass, and aluminium. The cost-effective operations have replaced CO2 use in many applications.

- Laser cutting via Voice-Activated Control Systems.

- Ultra-fast 5G-Enabled Operations for reliable and smooth laser cutting.

- CAD/CAM integration to streamline the workflow from design to production.

- AI & IoT is truly the smartest combination ever created for laser cutting machines. This latest trend has multiplied the possibilities by reducing downtime and increasing production. These adaptive laser cutting machines work on customised cutting strategies for different materials. Medical, automotive, and sheet metal fabrication are real-time examples of AI & IoT in laser cutting. Undoubtedly, AI and IoT have brought a huge revolution in the laser cutting industry. If you, too, are looking for next-generation laser cutting in Pune, Cyclotron is the best laser cutting service provider with a proven track record.

Best Laser cutting services by Cyclotron Industries. We offer high precision, fast and accurate laser cutting solutions for any kind of metal applications

Laser cutting services

Laser cutting services in Pune

Fiber laser cutting services in Pune

Metal laser cutting services in Pune

Laser cutting for sheet metal parts

CNC Laser cutting services in Pune