Laser cutting for sheet metal parts

Laser cutting for sheet metal parts

Cyclotron industries provide the most precise laser cutting for sheet metal parts whether it is MS, Aluminium or SS. You can rely for all your laser cutting needs. Let’s deep dive into laser cutting for sheet metal parts.

Need help finding top-notch laser cutting services in Pune for sheet metal?

Laser cutting has become a quintessential subtractive manufacturing process for metal fabrication. Its ability to deliver precise cuts and burr-free edges without compromising on quality has made it an exceptional choice for a wide range of industries.

Whether you are a new or existing venture, this comprehensive guide is a must-read to clear all your doubts and boost production flow in cutting sheet metal parts.

Best Laser cutting services by Cyclotron Industries. We offer high precision, fast and accurate laser cutting solutions for any kind of metal applications

Introduction to Laser Cutting for Sheet Metal

- Laser cutting for sheet metal parts is by far the most versatile and precise method for transforming metal sheets into intricate designs.

- Based on CNC-controlled technology, laser cutting is the most reliable and stable light path system for cutting metal sheets ranging from thin to thick. Adhering to global standards, laser cutting has become the preferred manufacturing technique for multiple industries, including construction, aerospace, and automotive.

- The high-powered laser beam can cut through various metals, providing clean cuts and smooth edges at high speed. Before you venture into metal laser cutting, we recommend reading this detailed guide to learn about different metals, the metal laser cutting process, its applications, and various parameters to consider.

Sheet metal laser cutting, also known as sheet metal fabrication, is the process of manufacturing simple to complex metal parts by cutting through flat metal sheets of varying thickness. Unlike plate cutting, sheet metal laser cutting is effective on almost all types of metals, including stainless steel, carbon steel, aluminum, and copper. It is significantly more flexible, versatile, and precise for metals with a thickness greater than 25mm.

Laser cutting for sheet metal is a non-contact, thermal process controlled by a CNC (Computer Numerical Control) system. It takes design from CAD/CAM software and rapidly moves the laser head with high precision and accuracy.

As discussed in the previous section, laser cutting for sheet metals offers numerous advantages over traditional cutting methods. Besides metal’s thickness, there are many other distinctions between sheet metal laser cutting and other techniques to streamline the manufacturing workflow. Take a look!

1.High precision & accuracy

Metal laser cutting is ideal for cutting complex & intricate designs through thin metals with high precision. It can achieve tight tolerances of up to ±0.1 mm or better.

2. Minimal material wastage

A high-intensity CNC-controlled laser beam is concentrated on a tiny spot at high speed, ensuring minimal material wastage.

3. Smooth edges & reduced finishing work

The entire fabrication process produces almost perfect metal parts with burr-free edges and a narrow kerf width. Most often, it doesn’t require any finishing process.

4. High speed

As no mechanical tools are required, sheet metal laser cutting offers high speed & efficiency as compared to traditional cutting methods.

Best Laser cutting services by Cyclotron Industries. We offer high precision, fast and accurate laser cutting solutions for any kind of metal applications

Sheet Metal Laser Cutting Process

It uses optics and a CNC-controlled system to create metal components while maintaining speed, accuracy, and consistency. The pre-programmed CNC system moves the laser head to the specific path. The metal laser cutting procedure typically involves:

1.Design & CAD/CAM programming: In the initial phase, a design file is created using CAD/ CAM software. The software is then converted into G-code, which contains the laser path and design.

2. Material setup and thickness considerations: The metal sheet is loaded into the laser cutter while the operator adjusts other performance parameters (speed, power, focal length, etc.)

3. Cutting operation: This phase involves generating a Laser beam using a CO2 or fiber laser and focusing on the surface of the metal sheet. The concentrated laser beam heats, melts, and vaporises the metal until the desired cut is obtained. Finally, an assist gas (oxygen/ nitrogen) is ejected to blow away the burr from the edges.

4. Inspection & quality checks: The final metal part is thoroughly inspected for quality in accordance with global industry standards. Most often, laser cutting doesn’t require any additional processes, such as anodizing or heat treatment.

Sheet metal laser cutting has become essential for various industries that require both signage and functional metal parts. Here are some key applications and industries relying on laser cutting for sheet metal parts.

Automotive & Aerospace

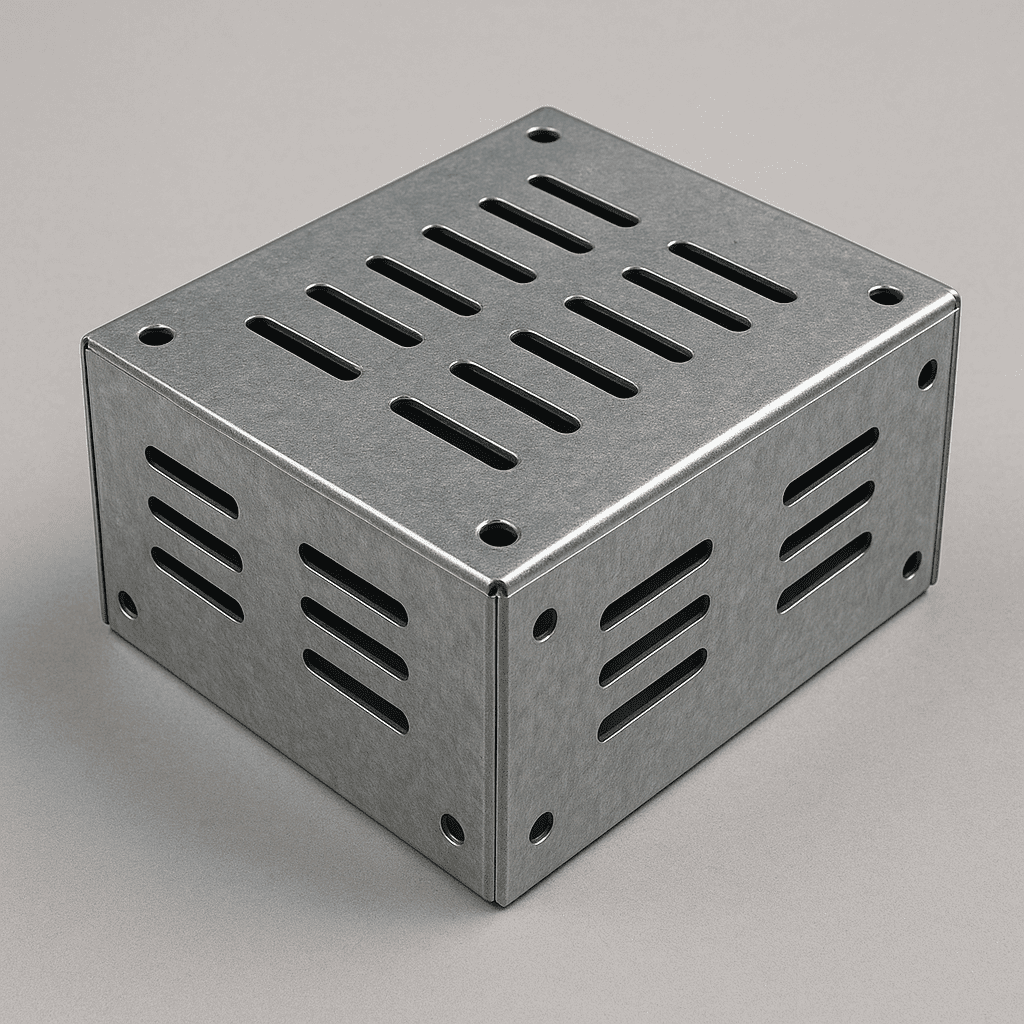

Metal laser cutting is widely used in this high-stake industry to create body panels, brackets, electronic enclosures, and chassis components.

Industrial machinery parts

From heavy-duty fixtures and control panels to consumer electronics casings, machining tools, jigs, and housing equipment, all are designed & cut using sheet metal laser cutting.

Signage & decorative products

Metal laser cutting is renowned for cutting complex geometric designs with unmatched precision and quality. This technique is used to create custom designs for Metal lettering, decorative screens, and metal art pieces.

Whether it’s a single prototype, small-batch production or mass volume production, custom laser cutting services for sheet metal offer a flexible and tailored design for OEMs. Here are some key advantages of custom sheet metal fabrication:

- Clean edges and high precision for intricate designs.

- Design flexibility allows rapid prototyping.

- Cost-effective for low-volume production.

- Quick turnaround & lead time due to automation.

- Maximise material utilisation & minimal heat distortion

| Features | Laser Cutting | Plasma Cutting | Punching / Stamping |

|---|---|---|---|

| Edge Quality | Smooth & burr-free edges with no additional finishing requirement. | Creates metal parts with wider kerf and slag. | Rough edges require expensive finishing. |

| Precision & Tolerance | Due to CNC control, it can achieve extremely tight tolerances (±0.1 mm or better). | Low precision as compared to laser cutting. | Physical tools limit the precision level. |

| Material Distortion | An intense laser beam is targeted on a very small spot to reduce material wastage. | High risk of material warping due to mechanical stress. | The heat-affected zone (HAZ) is larger. |

Cyclotron is among the top-rated industry leaders, known for its innovative and exceptional Laser cutting services in Pune. We offer cutting-edge custom and bulk sheet metal solutions, incorporating advanced CNC fiber laser machines. With experience in serving multiple industries, Cyclotron promises to deliver high-quality, precision-pressed metal products with dimensionally accurate cuts. Based in Pune, Cyclotron is a wise choice for sheet metal laser cutting services. Due to Pune’s strategic location and robust manufacturing ecosystem, industries are likely to benefit from global standard sheet metal fabrication at competitive prices.

Best Laser cutting services by Cyclotron Industries. We offer high precision, fast and accurate laser cutting solutions for any kind of metal applications

Laser cutting services

Laser cutting services in Pune

Fiber laser cutting services in Pune

Metal laser cutting services in Pune

Laser cutting for sheet metal parts

CNC Laser cutting services in Pune