Fiber laser cutting services in Pune

Fiber laser cutting services in Pune

When tolerances matter, Pune’s fiber lasers make every millimeter count.

According to Verified Market Reports, the fiber laser cutting services market was valued at USD 1.2 billion in 2024 and is expected to reach USD 2.5 billion by 2033, growing at a compound yearly growth rate (CAGR) of 9.0% between 2026 and 2033.

This dramatic rise reflects the rising demand for precision, speed, and cost-effective manufacturing solutions across various industries.

Pune, known as the “Oxford of the East,” is a city in India that is reputed for its educational institutions, IT companies, and manufacturing industries. One industry that has been gaining prominence in recent years is the laser cutting machine manufacturing industry. Pune is now home to several reputable laser cutting machine manufacturers that cater to a wide range of industries such as automotive, aerospace, electronics, and more.

If you’re considering investing in a laser cutting machine for your business, this post explains why choosing Fiber laser cutting services in Pune is a wise decision.

Best Laser cutting services by Cyclotron Industries. We offer high precision, fast and accurate laser cutting solutions for any kind of metal applications

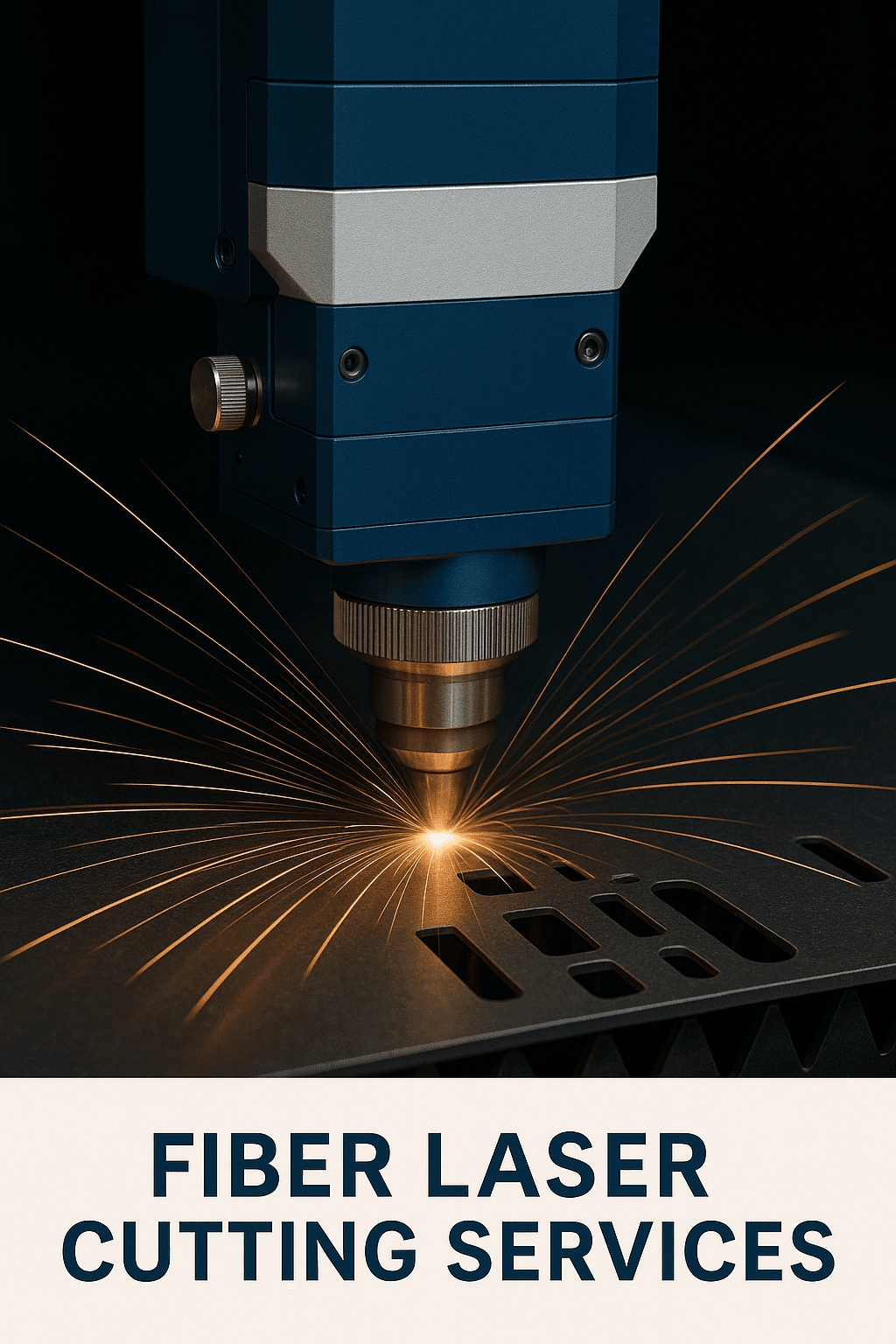

Introduction to Fiber Laser Cutting

- Fiber laser cutting is an industrial technology that utilizes the heat generated by a fiber laser to melt and remove material from a workpiece, resulting in a clean cut. The "laser" stands for Light Amplification Stimulated Emission of Radiation.

- Fiber laser technology utilizes a very narrow light beam directed at the target material. A moving optics system within the laser machine focuses the light.

Fiber laser cutting focuses high-intensity light through an optical fiber to a spot, vaporizing or melting material, while a gas jet removes molten waste. This yields precise, fast cuts with narrow kerfs and low HAZ overall.

- Technology Behind Fiber Lasers

A doped optical fiber (ytterbium) is the gain medium; pump diodes excite ions to emit coherent light. It provides high efficiency, excellent beam quality, compactness, and low maintenance.

| Feature | Fiber Laser | CO₂ Laser |

|---|---|---|

| Wavelength | ~1.06 µm (near-infrared) | ~10.6 µm (mid-infrared) |

| Beam quality & spot size | Excellent beam quality → very small focal spot, finer detail and narrower kerf | Larger spot size → lower resolution, wider kerf |

| Energy absorption (metals) | Higher absorption in most metals (stainless, brass, copper) — more efficient cutting | Lower absorption in reflective metals; less efficient on some metals without special setup |

| Cutting speed | Faster on thin–to–medium metal gauges due to small spot & high power density | Slower on same thickness at equal power; competitive on some thicker plates |

| Material suitability | Best for metals (steel, stainless, aluminium, copper, brass); some plastics with care | Good for non-metals (wood, acrylic, leather) and sheet metals; used for thicker mild steel at high power |

| Edge quality & HAZ | Cleaner edges, narrower HAZ, less dross | Edges can be rougher with a wider HAZ at comparable settings |

| Reflective material handling | Handles reflective metals better (reduced back-reflection risks with proper optics) | More sensitive to back-reflection; requires careful setup for copper/bright metals |

| Efficiency & energy use | High electrical-to-optical efficiency → lower energy consumption | Lower efficiency → higher power draw for same output |

| Maintenance & uptime | Fewer moving parts, sealed fiber — lower maintenance, high uptime | Require optics alignment and gas handling; generally higher maintenance |

| Operating & running cost | Lower operating cost (energy + consumables) over time | Higher operating cost (energy + optics/gas) |

| Capital cost | Often lower for comparable cutting capability | Can be more expensive for equivalent metal-cutting performance |

| Typical applications | Precision metal fabrication, sheet metal, electronics parts, high-mix production | Signage, plastics, some heavy-duty metal cutting, legacy installations |

Advantages of Fiber Laser Cutting Services

Fiber laser cutting has revolutionized the manufacturing and fabrication industry by offering unmatched speed, precision, and efficiency. Below are some of the key advantages that make fiber laser cutting a preferred choice for modern industries.

- High Precision & Accuracy

Fiber lasers produce a focused, high-intensity beam that can cut intricate and complex shapes with extreme accuracy. This precision is important for industries like aerospace and electronics, where every millimeter counts. - Faster Cutting Speed

Compared to old cutting methods, fiber lasers are significantly faster, especially on thin materials. Their high-speed operation reduces production time and increases the output, allowing businesses to fulfill orders more quickly and efficiently. - Clean Edges & Minimal Post-Processing

The high-quality cuts produced by a fiber laser result in smooth, clean edges with minimal to no burrs. This reduces or even eliminates the need for additional finishing work, saving both time and labor costs in the manufacturing process.

Fiber laser cutting is a fast, clean way to cut metal and some other materials. In Pune, with its automotive hubs, factories, and builders, this technology is widely used because it is precise, quick, and minimizes material waste.

Automotive & Transport

Fiber lasers cut car body panels, chassis parts, fuel tank components, and exhaust parts with high accuracy. They are suitable for both one-off prototypes and large production runs. The cuts are clean, so parts fit together better, which helps reduce rework and saves time on the shop floor.

Aerospace & Defense

In aerospace and defense, fiber lasers cut thin and thick metal sheets used for frames, brackets, and engine parts. The lasers make exact cuts with small heat-affected zones, which keeps the metal strong and reliable. This precision is essential for safety and for parts that must meet strict standards.

Industrial Machinery

Manufacturers in Pune use fiber lasers to cut gears, frames, flanges, and hydraulic component plates. The technology gives consistent shapes and sizes (good repeatability), so machines work smoothly and last longer. It also accelerates custom jobs and small batches without significantly increasing costs.

At Cyclotron, we deliver fast, accurate fiber laser cutting using modern machines, expert engineers, and customized solutions for industries like automotive, aerospace, and construction. Here is why you should invest in Cyclotron for Fiber laser cutting:

Advanced Fiber Laser Cutting Machines

We use up-to-date fiber lasers that give clean, precise cuts fast, so your parts need less finishing and stay consistent.

Expertise in Precision Engineering

Our technicians understand materials and tolerances. Our dedicated engineers fine-tune settings and inspect jobs so parts fit and work exactly as intended.

Serving Multiple Industries with Custom Solutions

We help automotive, aerospace, construction, and industrial clients. We adapt processes to your drawings, timelines, and special requirements.

Best Laser cutting services by Cyclotron Industries. We offer high precision, fast and accurate laser cutting solutions for any kind of metal applications

Laser cutting services

Laser cutting services in Pune

Fiber laser cutting services in Pune

Metal laser cutting services in Pune

Laser cutting for sheet metal parts

CNC Laser cutting services in Pune