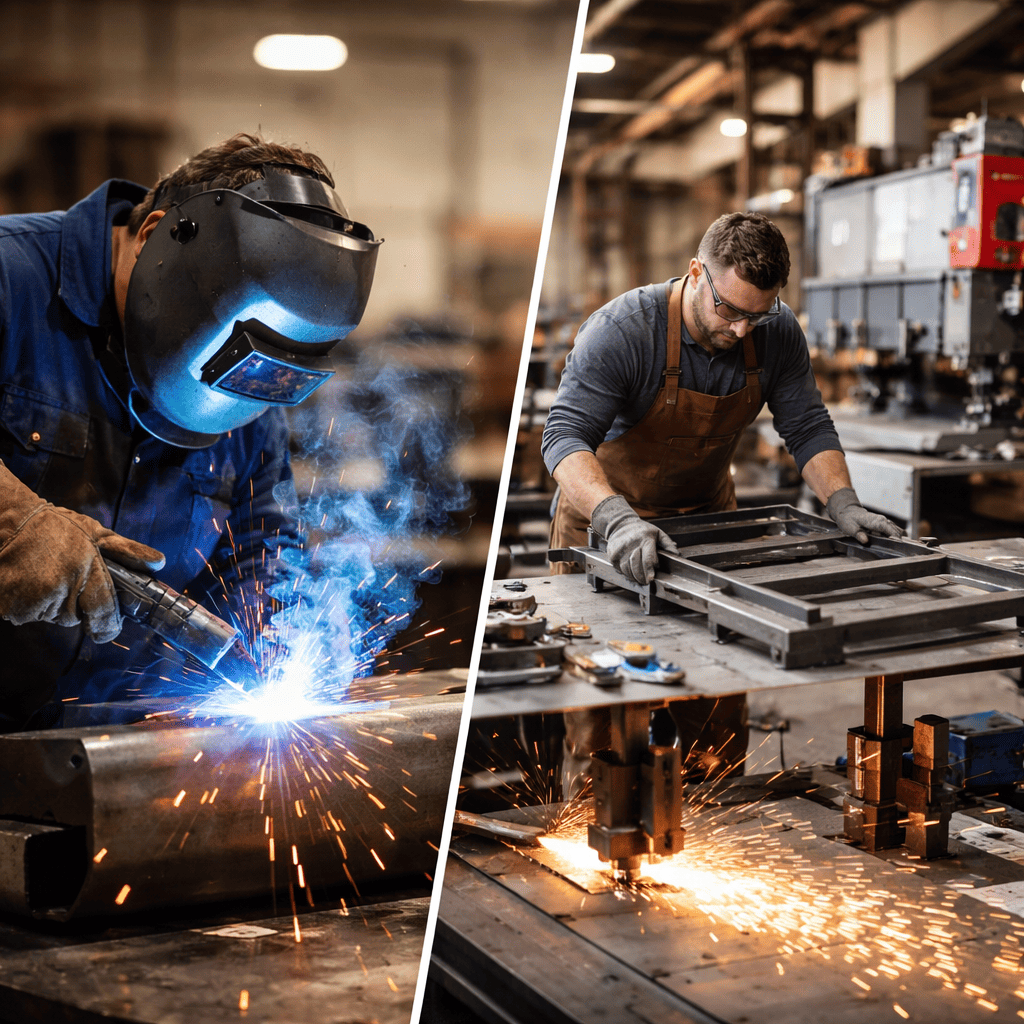

What is difference between welding and fabrication?

What is the difference between welding and fabrication?

- Welding simply means the process of joining two metals together whereas fabrication involves the complete cycle right from cutting, bending, alignment, welding and inspection, etc

- Welding is one of the part of the complete fabrication process

- Today, let’s clearly define what is the difference between welding and fabrication, especially from the B2B perspective. Welding is one operation in the manufacturing chain. Fabrication is the workflow that controls cutting, bending, alignment, welding, and inspection as a single responsibility.

- When this distinction is unclear, problems do not appear immediately. They surface later during assembly, commissioning, or service, when corrections are slower and more expensive.

Welding vs fabrication: Key differences

| Factor | Welding | Fabrication |

|---|---|---|

| Primary Function | Joins two metal parts permanently. | Converts raw material into final useful parts or assemblies. |

| Position in Workflow | Single operation within the manufacturing chain. | Constitutes the complete manufacturing workflow. |

| Scope of Responsibility | Limited to the joint it creates. | Owns responsibility from fitment and alignment to final outcome. |

| Control over Geometry | No control over part geometry. | Full control from cutting to final assembly. |

| Accuracy | Assumes accuracy already exists. | Creates and protects accuracy. |

| Handling Tolerances | Works within defined tolerances. | Defines, manages, and validates tolerances. |

| Problem Identification | Problems appear early and are visible. | Problems often appear late during assembly. |

| Role in Load Behavior | Joins members as positioned. | Determines load paths and force distribution. |

| Cost of Errors | Localized errors; easier to rework. | Errors compound and are expensive to correct later. |

| Influence on Distortion | May induce heat distortion. | Plans geometry, sequencing, and fixturing to manage distortion. |

| Role in OEMs | Limited, task-based use. | Critical for OEM and industrial manufacturing. |

Best fabrication services by Cyclotron Industries. We offer high precision, fast and accurate fabrication solutions for any kind of metal applications

Why Welding and Fabrication Are Constantly Mixed Up in B2B Manufacturing

The confusion rarely comes from a lack of technical understanding. It comes from how work is discussed and handed over.

Most projects do not begin with a detailed RFQ. They start with a sketch sent on a short phone call or a brief quote. A line in an email that says, “welding and fabrication required.” Over time, fabrication gets shortened to welding. Not because the processes are the same, but because welding is the most visible part of the work.

You can see welding. You can hear it. You can judge it quickly.

Fabrication happens in the background. Cutting accuracy. Bend consistency. Datum selection. Fixturing. Weld sequence planning. These decisions are rarely visible, yet they determine whether parts align, assemble, and perform long before the first weld is laid.

The welding and fabrication mix-up becomes more common when work is split across vendors. One shop cuts. Another one performs bending. A third workfloor welds. Each step may be completed correctly in isolation. The assembly still fails. No single party owns the final outcome, and welding becomes the easiest operation to question because it is the last and visible.

Commercial pressure contributes as well. Welding sounds narrower and easier to price. Fabrication sounds broader and risk-heavy. Buyers often use narrower language even when the work clearly requires fabrication-level responsibility. The intent is usually cost control. The result is often misalignment.

The real problem is timing. Individual parts may look fine. Welds may pass inspection. Issues appear later during assembly or commissioning, when the cost of fixing them is far higher and the cause harder to trace.

Why This Difference Matters to OEMs & Engineering Teams

Treating welding and fabrication as the same process does not cause part failure. It causes loss of ownership.

Calling a requirement “welding work” quietly removes responsibility for cutting accuracy, bend consistency, alignment strategy, and inspection. These elements become assumed rather than owned.

For OEMs, this shows up during integration. Parts are made. Welds look acceptable. Assemblies still do not fit. What should have been a routine assembly becomes modification work. Time is lost not because anyone did poor work, but because no one owned the entire result.

From a procurement perspective, this is where costs begin to leak. Initial quotes appear competitive. Additional work appears as rework, coordination, handling, or late changes. None of this is visible during initial comparison, but all of it affects delivery and budget.

Engineering teams experience the effect directly. Instead of improving designs, time is spent granting deviations, resolving fitment issues, and explaining why parts behave differently in metal than in CAD.

The issue worsens with scale. A prototype can tolerate adjustment. Batch production cannot. Small discrepancies become recurring problems, and the distinction between welding and fabrication becomes operational rather than semantic.

Welding Vs Fabrication: Explaining In Detail

Welding: What It Covers

Welding is a defined operation with a clear role. In OEM and industrial manufacturing, welding is responsible for:

- Permanently joining metal components

- Creating structural continuity at joints

- Transferring loads between already-positioned parts

What welding does well:

- Produces strong, repeatable joints

- Performs reliably when geometry is already correct

- Supports both structural and non-structural assemblies

Welding assumes that parts are already correct in size, shape, and position.

Where Welding Has Limits

Welding is often expected to solve problems it was never designed to handle. Welding does not:

- Decide on part geometry or overall dimensions

- Correct cutting or bending inaccuracies

- Resolve misalignment between components

- Manage tolerance stack-up across assemblies

By the time welding begins, the material has already been cut, formed, and positioned. Welding simply locks those decisions in place.

This is why good welds can exist in assemblies that do not fit or perform as intended. Welding executes decisions. It does not make them. Welding simply locks these decisions in place.

Fabrication: The Part of Manufacturing That Actually Carries the Risk

The risk of manufacturing is being silently transferred to fabrication. Not because it is sloppy work, but because this is where decisions get locked into metal.

Fabrication is not concerned with isolated joints, unlike welding. It concerns geometry, part associations, and the behavior of those associations under loads, during assembly, and through repeated assembly.

For this reason, fabrication is not a service in the usual sense. It is a workflow.

In the welding vs fabrication, fabrication answers questions that never reach welding:

- Are mating surfaces truly square and parallel?

- Will the structure remain straight after welding and loading?

- Will the assembly repeat consistently in the next batch?

- Will finishing affect fitment or clearance?

If these questions are not addressed early, they reappear later during assembly or commissioning, when changes are slow and costly.

Core Fabrication Stages

Fabrication is a sequence. Decisions are passed off from one stage to another. Minor mistakes do not add up to nothing.

Cutting

Cutting defines reference. Hole locations, profiles, and edge squareness are set here. Errors are rarely seen, but they propagate downstream. Fabrication treats cutting as a precision step, not just material removal.

Bending and Forming

This is where geometry moves from 2D to 3D. Small angular variations shift interfaces and introduce fitment issues that only become visible during assembly. Springback control and consistency are fabrication responsibilities.

Machining (When Required)

Machining provides accuracy where fabrication alone cannot. Alignment-critical interfaces and precision features belong here. Omitting machining where required leads to vibration, wear, or early service issues.

Welding and Sub-Assembly

By this stage, geometry should already be verified. Welding fixes decisions permanently. Alignment or stability issues introduced earlier cannot be corrected through welding skills alone.

Inspection and Finishing

Inspection must verify functional dimensions, not appearance alone. Corrections made here are still possible. Corrections deferred to final assembly or site work are not.

These corrections can be done at this point. Any corrections made during final assembly or on-site are not.

Best fabrication services by Cyclotron Industries. We offer high precision, fast and accurate fabrication solutions for any kind of metal applications

Processes in Metal fabrication

Milling: Milling removes metal using rotating cutting tools. It is used when flat surfaces or defined shapes are needed on a part. This process works for both simple cuts and more detailed profiles. Milling is used for flat faces, grooves, keyways, and parts where dimensions need to stay controlled. It is especially helpful when fabricated parts must sit flush or match properly during assembly.

Drilling: Drilling is done to create round holes in metal parts. It is one of the most common machining operations used in fabrication work. Drilling is typically used for bolt holes, fastener locations, and openings for wiring or piping. It is also done before tapping or reaming. When drilling is accurate, parts line up better during assembly and maintain strength in the final build

Turning: Turning is done on a lathe, where the part rotates while a cutting tool shapes it. This process is mainly used for round or cylindrical components such as shafts, pins, and bushings. It is chosen when parts need proper concentricity and a smooth surface finish. Turning is often used along with fabrication when round parts are part of a larger assembly.

Tapping: Tapping is used to create internal threads inside drilled holes. This allows bolts or screws to be fastened directly into the metal. It is commonly used in plates, brackets, and frames where using nuts is not practical. The tapping process makes assembly faster and avoids the need for additional hardware.

Welding in Metal fabrication

Welding is the most common joining method in metal fabrication. It permanently fuses metal parts together using heat and, in some cases, filler material. Different welding techniques are chosen based on material type, thickness, strength requirements, and production volume.

- MIG Welding

MIG welding is reputed for its speed and ease of operation. It is suitable for mild steel, stainless steel, and aluminum and is commonly used in general fabrication and production work. - TIG Welding

TIG welding offers greater control and produces clean, high-quality welds. It is preferred for thin materials, critical components, and applications where appearance and precision matter. - Stick Welding

Stick welding is robust and versatile, making it suitable for heavy fabrication, outdoor work, and thick materials. It is often used where conditions are less controlled. - Robotic Welding

Robotic welding is used in high-volume and repetitive fabrication jobs. It delivers consistent weld quality, improves productivity, and reduces human error, making it ideal for OEM and industrial production.

- MIG Welding

FAQs

1. Is welding the same as metal fabrication?

No. Welding is only one part of metal fabrication. Fabrication covers the full process, starting from raw material and ending with a finished product. That includes cutting, forming, machining, welding, finishing, and final assembly. Welding is used to join metal parts together, but by itself, it does not complete a fabricated component.

2. Which metals are easiest to fabricate?

Mild steel and aluminum are generally easier to fabricate compared to other metals. Mild steel is widely used because it is affordable and responds well to cutting, bending, and welding. Aluminum is lightweight and machines easily, though it needs the right welding techniques. In practice, ease of fabrication also depends on material thickness, part design, and the tolerances required.

3. What affects the cost of fabrication?

There isn’t one fixed cost for fabrication. It depends on the job. The type of metal, how thick it is, and how complex the design needs to be all matter. Some parts go through more fabrication steps than others. Cutting, machining, labour time, surface finishing, and production quantity also affect pricing. If tolerances are very tight, the design is custom, or the delivery needs to be faster, the cost usually increases.

4. How does sheet metal fabrication differ from heavy fabrication?

Sheet metal fabrication is done on thinner material. It focuses more on details, Accuracy and bend quality. You see this kind of fabrication in panels, enclosures, and lighter components.

Heavy fabrication works with thick plates and large sections. It is used for structures and heavy equipment, where strength comes first. The machines and methods used are very different from sheet metal work.

Cyclotron group clients

Best fabrication services by Cyclotron Industries. We offer high precision, fast and accurate fabrication solutions for any kind of metal applications