Metal fabrication services in India

Cyclotron Industries offers Metal fabrication services including steel fabrication, custom fabrication, welding & heavy engineering solutions across India.

- Cyclotron Industries offers a full range of metal fabrication services from concept and prototyping through to production, finishing, and assembly.

- We combine engineering experience from the Cyclotron Group with industrial equipment and controlled processes.

- The result is reliable metalwork for OEMs, machinery builders, and heavy engineering companies across Pune and neighboring industrial areas.

Steel fabrication services is one of our core capabilities, with dedicated setups for both mild steel (MS) and stainless steel (SS). Each material requires a different process, so MS and SS fabrication are handled with separate tools, techniques, and finishing standards.

1. Mild Steel (MS) Fabrication

MS is widely used in industrial projects, and we handle everything from light sheet-metal parts to heavy MS structures.

- Structural components: Beams, supports, brackets, and load-bearing frames

- Machinery frames: Stable, well-aligned MS frames built with controlled welding and proper fixturing

- Industrial supports: Stands, bases, and reinforcement structures designed for long-term load and vibration

Our Mild Steel fabrication work supports OEMs, automation builders, manufacturing units, and construction projects across Pune.

2. Stainless Steel Fabrication

Stainless Steel fabrication needs clean welds, smooth finishing, and careful handling to protect the surface of the material.

- Food-grade fabrication: TIG-welded covers, enclosures, tables, and guards

- Pharma equipment: Panels, housings, supports, and fixtures for cleanroom use

- Decorative and architectural SS: Handrails, frames, guards, and display units with polished finishes.

- Precision SS parts: Laser-cut, CNC-bent, TIG-welded components for machinery and automation

Our steel fabrication services cover both heavy MS structures and high-finish SS assemblies, giving customers reliable results across different applications.

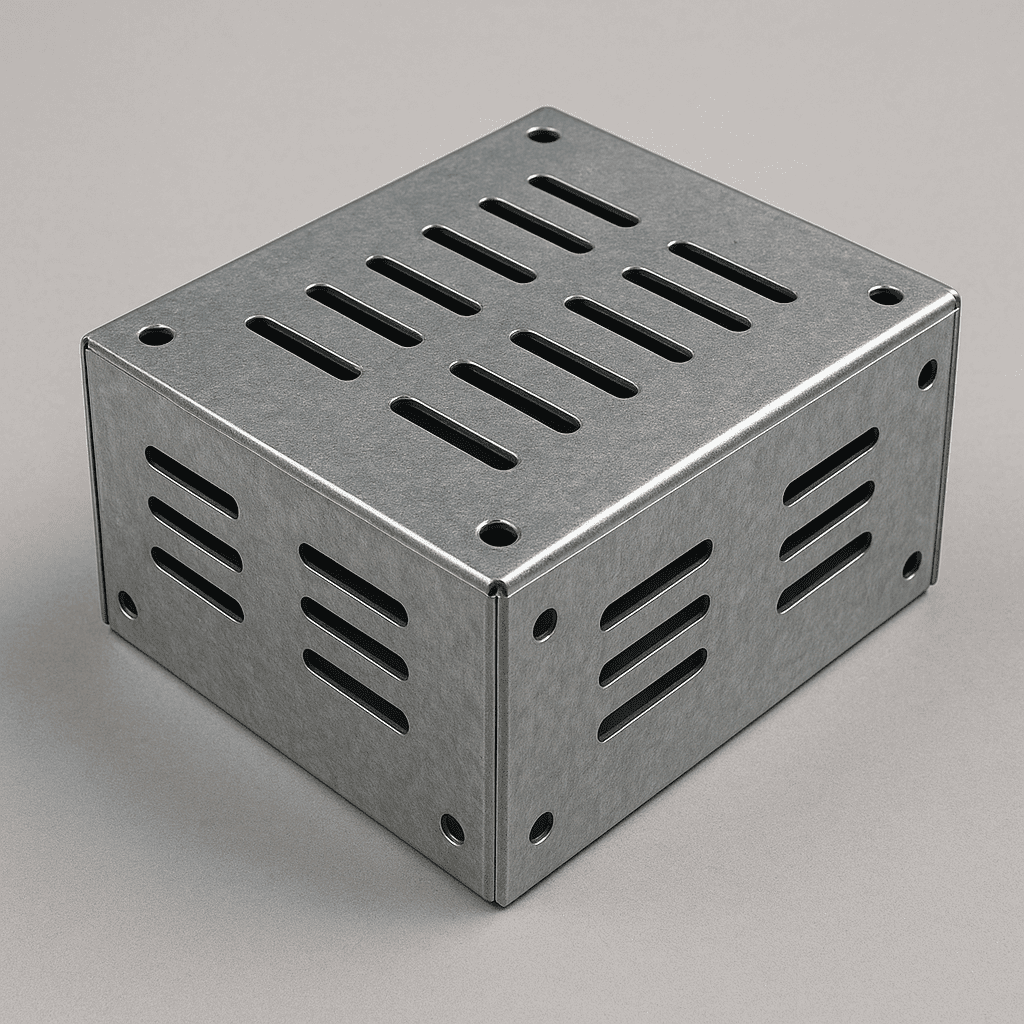

- Sheet metal fabrication services deals with thin metal sheets that are cut, bent, and assembled into precise shapes. It is widely used where lightweight and accuracy are important.

Common uses:

- Electrical panels and enclosures

- HVAC ducts and cabinets

- Panels, brackets, and covers

Choosing the right fabrication partner matters a lot when your production schedule, equipment performance, and long-term reliability depend on the parts you receive. Over the years, many OEMs and industrial companies across Pune have continued working with us because they see consistency in our work and clarity in the way we handle every project. Here are the reasons our customers consider us their preferred fabrication partner.

1. Advanced Machinery

Our workshop is equipped with industrial-grade machines that support laser cutting, CNC bending, machining, and controlled welding. This allows us to produce accurate components with steady results, even in large batches.

2. Skilled Welders and Fabricators

Good fabrication depends on the people doing the work. Our welders and fabricators understand how metal behaves during cutting, bending, and welding, which helps them maintain alignment and reduce distortion.

3. Engineering-Led Team

Every project begins with an engineering review. Drawings, tolerances, and material details are checked before production starts. This prevents rework and ensures the final part fits correctly in the customer’s assembly.

4. ISO-Level Quality Control

We follow structured inspection steps that reflect ISO-style quality practices. Critical dimensions, weld integrity, and surface finishing are checked throughout the process so that each batch meets the required standard.

5. Fast Prototyping

We support development teams and OEMs with rapid prototyping. Quick iterations, direct communication, and small adjustments help customers validate designs faster before moving to full production.

6. Strong Finishing Capabilities

Finishing is a major part of the final product. Powder coating, painting, surface preparation, and polishing are handled with care to make sure the part looks clean and remains protected in its working environment.

7. One-Stop Fabrication Facility

Cyclotron Industries manages cutting, bending, welding, machining, finishing, and assembly under one roof. This reduces coordination effort, speeds up delivery, and improves overall control over quality.

- Fabrication services hsn code is 9988 with a GST Rate of 18% in India under the name of General fabrication work.

- Businesses involved in mild steel fabrication should use HSN codes like 998873 or 7308, depending on whether it is a product manufacturing service or a structural fabrication.

- SS fabrication typically falls under HSN 998873 or similar structural codes, attracting an 18% GST rate.

- Cyclotron Industries is the best Custom metal fabrication services in India. Custom fabrication is the process of transforming raw material into an exact product with the desirable dimensions, shape, and properties required by the customer.

- Custom metal fabrication comprises a series of processes like cutting, bending, welding, machining, and assembly of metal parts to match the customer’s exact design requirements

This is why custom fabrication services are so popular. They allow you to choose the right material, the right thickness, and the exact dimensions so the final part fits perfectly without any adjustments on the shop floor.

Custom Steel Fabrication

We handle heavy-duty steel fabrication for frames, supports, machine structures, and general industrial work. As a custom steel fabrication company, we build parts that can take higher loads and rough working conditions.

Custom Aluminum Fabrication

Aluminum is lightweight and corrosion-resistant, so it’s great for precision brackets, panels, and machine parts. Our custom aluminum fabrication service is ideal when you need strong parts without adding extra weight.

Custom Mild Steel (MS) Fabrication

Mild Steel is one of the prominently used materials in fabrication because it’s strong, easy to work with, and budget-friendly. We build MS cabinets, stands, bases, machine frames, and general fabrication items for all industries.

Stainless Steel (SS) Fabrication

Stainless Steel is used when you require corrosion resistance and clean finish. The stainless steel fabrication finds its use in food processing, pharma, chemical plants, and automation equipment industries.

At Cyclotron Industries, fabrication is handled end-to-end. Cutting, bending, welding, fit-up, and inspection are treated as linked stages, with responsibility carried through the entire build.

This approach supports OEMs and industrial manufacturers who need assemblies that fit cleanly, repeat reliably, and perform predictably in service.

If you are reviewing drawings or preparing an RFQ, an early technical discussion often prevents months of downstream friction.

Custom fabrication services usually involves cutting, bending, welding, machining, and assembly. What makes it “custom” is not the process itself, but how these steps are planned and connected. Decisions are made keeping the final fit and function in mind, not just individual operations.

A custom metal fabrication company in India works closely with OEMs and industrial buyers to turn design intent into working assemblies. The focus stays on alignment, strength, and repeatability, so parts fit without force and perform as expected once installed.

In simple terms, custom metal fabrication is not just about making metal parts. It is about making them work in the real world.

Cyclotron Industries is trusted by OEMs and project contractors in Pune for heavy fabrication work that requires accuracy, strength, and consistent quality. Our facility, equipment, and team are built to support large structures, thick-plate fabrication, and project-driven requirements across multiple industries.

Cyclotron operates a well-equipped fabrication shop with dedicated bays for cutting, welding, machining, and assembly. The layout allows smooth handling of large components and long fabricated structures

Blogs by Cyclotron Industries

Heavy fabrication plays a vital role in modern manufacturing, especially in industries that depend on large, strong, and long-lasting metal structures.

Everything about how ai for improving laser cutting is used worldwide. Iot and ai have been transforming the metal cutting industry and it’s trends.

Metal fabrication transforms raw metal into functional, dependable products through a structured sequence of processes

Fabrication work hsn code is 9988 with a GST Rate of 18% in India under the name of General fabrication work. Sheet metal, SS or aluminium fabrication HSN code

Welding simply means the process of joining two metals together whereas fabrication involves the complete cycle right from cutting, bending, alignment, welding and inspection, etc

All the common welding techniques in heavy fabrication includes MIG, TIG, SAW, SMAW, etc. Details about them are mentioned in this blog