Guide for metal fabrication

Guide for metal fabrication

Looking for a detailed guide on metal fabrication to understand the different fabrication processes and their scope in modern industries? Then, you have landed on the right platform.

Want to know how metal fabrication is reshaping the manufacturing industry?Over the last few years, the demand and growth of Metal fabrication have risen globally, especially in construction, electronics, and energy sectors.

The skilled metal fabricators at Cyclotron won’t only share their expertise but will also help you choose the right fabrication process, technology, and equipment for your project.

Metal Fabrication Meaning

- As the name suggests, Metal fabrication is a process that transforms raw metal sheets (such as aluminium and stainless steel) into fully functional metal components or structures. This highly engineered process involves various techniques, including assembling, cutting, bending, and welding, to create customised and intricate metal shapes. Once the fabricated metal sheet is obtained, the finishing process (printing/ coating) is performed at varying degrees.

- Primarily, these fabricated metal pieces are assembled to form large metal products or weldments according to the requirements. Steel skeletons of modern buildings, HVAC systems, and jet engine parts are all real-life examples of metal fabrication.

- It won’t be wrong to say that metal fabrication is the core pillar of strength for almost every small to large industry in the manufacturing realm. Whether it is construction, transportation, healthcare, consumer goods, or the energy sector, metal fabrication serves a diverse range of industries.

The process of metal fabrication depends on the unique requirements (such as design and engineering plans) of an Industry. As every industry requires customised Metal products, fabricators offer different types of metal fabrication processes. Each process employs different assembly techniques and equipment to produce the finished metal product. Here we’ll discuss three common types of metal fabrication:

- Sheet metal fabrication

- Custom metal fabrication

- Structural/ heavy fabrication

Sheet Metal Fabrication

It’s a versatile metal fabrication technique that transforms flat metal sheets into desired metal parts or components. For example, automotive parts, electronic appliances, and consumer goods are all manufactured using this primary fabrication technique. This process typically involves:

- Design & Material Selection: This is the initial phase where fabricators choose materials and create prototypes using CAD software, tailored to the industry’s specific needs and goals.

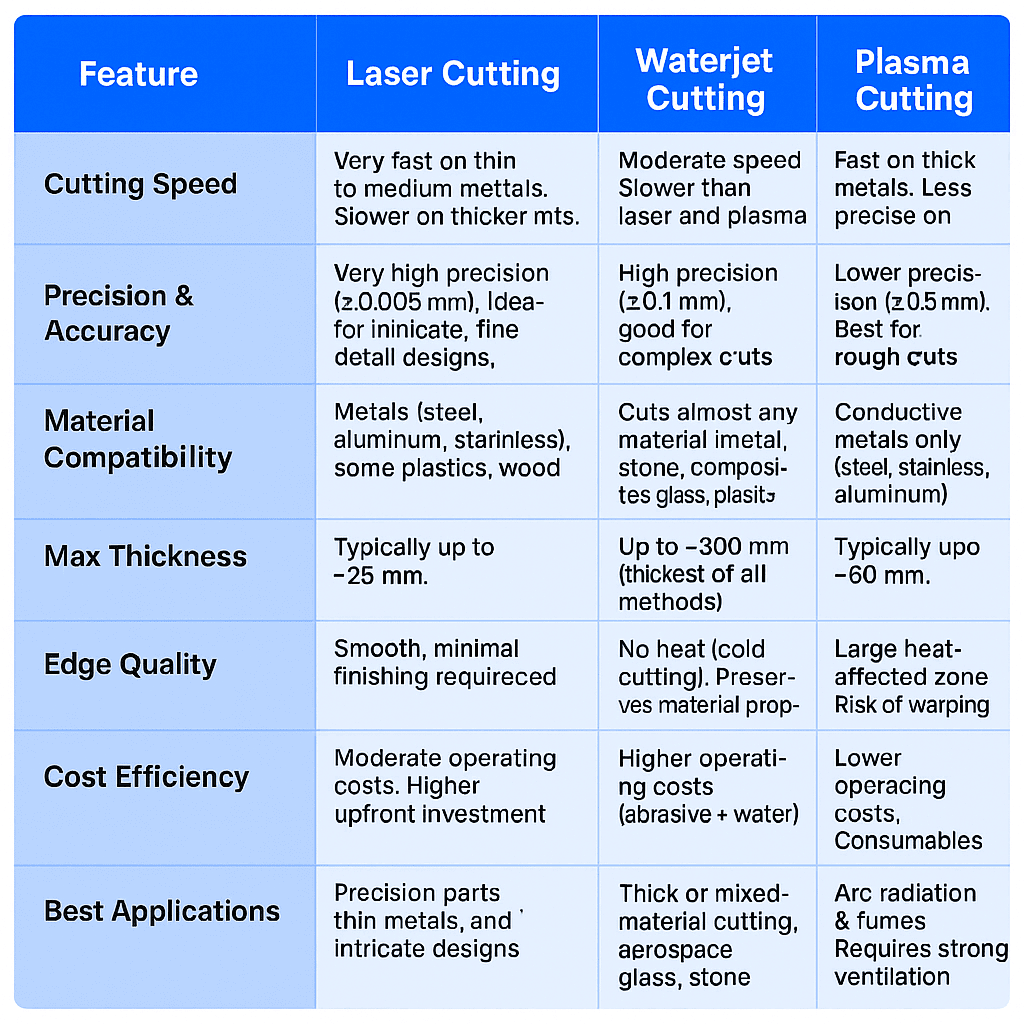

- Cutting & Profiling: This is a fundamental stage where raw metal sheets are cut into smaller sections using computer-controlled machining (CNC) techniques. Laser cutting, Plasma cutting, and Oxy-fuel cutting are some standard cutting & profiling methods.

- Bending & Forming: In this technique, the sheet metal workpiece is formed into a V or U-shape using advanced equipment, such as press brakes, at specific angles.

- Welding & Assembly: In this phase, skilled fabricators join fabricated metal parts together using various welding processes, including arc welding, MIG welding, and TIG welding.

- Finishing & Coating: This is the final stage, where the metal product is treated with a wet application of paint to resist corrosion or coated with powder for enhanced performance and efficiency.

It’s a high-demand and specialised process used to form unique or one-of-a-kind metal products. This collaborative process involves various key stages such as design & planning, material selection, fabrication, and finishing. Many industries like automotive, food processing, aerospace, and medical rely on the Custom metal fabrication process.

When standard solutions don’t fit, custom metal fabrication is the solution. Here’s why?

- Unique engineering plan & design

- Rapid Prototyping

- Reduced downtime & waste reduction

- Enhanced performance & precision

Structural/ Heavy Fabrication

This type of fabrication is typically employed for creating complex and large metal structures using fabricated metal components. Like metal fabrication, the structural fabrication process also includes:

- Different welding techniques

- cutting and machining

- Rolling & forming

Skyscrapers, long bridges, railroad tracks, tractors, large ducts, and mining equipment are all examples of heavy metal fabrication.

How to choose the right metal fabrication company? It’s a critical yet essential decision that will impact the appearance, performance, and success of your project. So, here’s the list of some crucial parameters to consider before making any random decision:

Expertise & technology

Hire a fabricator with experience, expertise in modern equipment and specific projects as per your requirement. Never hesitate to ask them about past projects and results.

Certifications & Quality Standards

Always opt for a metal fabrication company that is ISO certified, with a minimum standard of ISO 9001:2015 and AS9100D, to ensure quality and high performance. Also, check if they use advanced equipment to carry out measuring inspections.

Applications of Metal Fabrication Services

Construction

Undeniably, one of the most significant clients of metal fabrication in the manufacturing realm. From building bridges to structural components, Metal fabrication is the core element of their infrastructure.

Automotive & Aerospace

These industries rely on metal fabrication for designing internal components such as car chassis, engine brackets, heat shields, exhaust systems, and the outer body of the vehicle.

Energy Sector

Huge steel towers, turbines, piping, mounting for solar panels, and casings are all metal-fabricated products used to generate, transfer, and store energy.

Manufacturing

In the manufacturing sector, Metal fabrication helps create and assemble heavy machinery, equipment, automated conveyor belts, and much more with high precision.

FAQs on Metal Fabrication

1. What does metal fabrication mean? It’s a value-added process of shaping & building complex metal parts using raw sheets of metal, such as aluminium and steel.

2. What is the sheet metal fabrication process? Sheet metal fabrication utilises thin, flat metal sheets that are then transformed into valuable metal components.

3. What is the difference between sheet and custom metal fabrication? Sheet metal fabrication focuses on thin metal sheets. In contrast, custom metal fabrication works with all forms of metal, tubes, thick plates, structural beams, and bars to form complex yet intricate metal parts.

4.How to find reliable metal fabrication companies near me? Before choosing a metal fabrication company, ensure they possess the necessary fabrication skills for your project. Other parameters to keep an eye on are Industry standards & quality assurance, experience, customer service, and clients’ feedback.

Best Custom fabrication services by Cyclotron Industries. We offer high precision, fast and accurate Fabrication solutions for any kind of metal applications

Laser cutting is a leading precision manufacturing method known for its versatility and accuracy. Discover its process and benefits in this guide.

Gases used in laser cutting include Oxygen, Nitrogen, Compresses gases, etc. Each gas has its own application for various metal cutting.