Fabrication work by Cyclotron Industries

Cyclotron Industries offers all types of Fabrication work including steel fabrication work, aluminium fabrication work, etc. based out in Pune, India.

Pune has grown into one of India’s most trusted industrial cities. It is home to thousands of engineering companies, OEMs, and Tier-1 suppliers that rely on precise fabrication every day. Behind many of these projects stands Cyclotron Industries, a company known for dependable fabrication job work in Pune.

Cyclotron provides a full range of metal fabrication services that combine technical skill, modern equipment, and practical experience. Each project is planned carefully so customers receive high-quality, accurate, and repeatable results.

Fabrication work covers the end-to-end transformation of metal parts from raw material to a finished, ready-to-use product.

When someone asks what fabrication work is, the answer is a set of planned steps: cutting, forming, welding, finishing, and assembly, all done to meet specific design and engineering needs

- Professionally, fabrication work is a step-by-step manufacturing process that relies on precision, material know-how, and skilled work.

Steel fabrication work is one of our core capabilities, with dedicated setups for both mild steel (MS) and stainless steel (SS). Each material requires a different process, so MS and SS fabrication are handled with separate tools, techniques, and finishing standards.

1. Mild Steel (MS) Fabrication

MS is widely used in industrial projects, and we handle everything from light sheet-metal parts to heavy MS structures.

- Structural components: Beams, supports, brackets, and load-bearing frames

- Machinery frames: Stable, well-aligned MS frames built with controlled welding and proper fixturing

- Industrial supports: Stands, bases, and reinforcement structures designed for long-term load and vibration

Our Mild Steel fabrication work supports OEMs, automation builders, manufacturing units, and construction projects across Pune.

2. Stainless Steel Fabrication

Stainless Steel fabrication needs clean welds, smooth finishing, and careful handling to protect the surface of the material.

- Food-grade fabrication: TIG-welded covers, enclosures, tables, and guards

- Pharma equipment: Panels, housings, supports, and fixtures for cleanroom use

- Decorative and architectural SS: Handrails, frames, guards, and display units with polished finishes.

- Precision SS parts: Laser-cut, CNC-bent, TIG-welded components for machinery and automation

Our steel fabrication services cover both heavy MS structures and high-finish SS assemblies, giving customers reliable results across different applications.

- Fabrication work hsn code is 9988 with a GST Rate of 18% in India under the name of General fabrication work.

- Businesses involved in mild steel fabrication should use HSN codes like 998873 or 7308, depending on whether it is a product manufacturing service or a structural fabrication.

- SS fabrication typically falls under HSN 998873 or similar structural codes, attracting an 18% GST rate.

Fabrication often appears simple at first glance. It might look like a series of processes of cutting, welding, and finishing metal, but those who work close to the shop floor know it is much more than that. True precision comes from the right mix of technology, craftsmanship, and process control.

At Cyclotron Industries, this balance is a core part of every project. The Pune facility brings together skilled fabricators and advanced machinery to deliver accuracy that customers can count on.

- Tight Tolerances: Each joint is welded to an accuracy of 0.1 millimeter. Careful fixturing and inspection ensure parts fit perfectly during assembly.

- Modern Setup: The workshop is equipped with MIG and TIG welding stations, fiber laser cutters, robotic welding systems, and modular welding tables that help maintain repeatable accuracy for every batch.

- Quick Turnaround: Projects are scheduled efficiently so that prototypes, medium runs, and production jobs are completed on time without any compromise in quality.

- PAN-India Service: Cyclotron’s base is in Pune, but the company supplies components and assemblies to clients across India.

At Cyclotron Industries, fabrication is handled end-to-end. Cutting, bending, welding, fit-up, and inspection are treated as linked stages, with responsibility carried through the entire build.

This approach supports OEMs and industrial manufacturers who need assemblies that fit cleanly, repeat reliably, and perform predictably in service.

If you are reviewing drawings or preparing an RFQ, an early technical discussion often prevents months of downstream friction.

When a client shares a drawing or design, the job does not begin immediately. The team at Cyclotron Industries first reviews every detail, checks feasibility, and ensures that the plan is practical and cost-efficient.

The entire process is designed to give clients full confidence at every stage.

- Design Submission: Clients provide DXF or STEP files. The design and production teams study them carefully and clarify any open points before work begins.

- Feasibility Review: Material choice, tolerance levels, and assembly fit are verified to make sure the job can be completed as planned.

- Quotation: Pricing is transparent and based on actual nesting and production data, so there are no hidden surprises later.

- Fabrication: Cutting, forming, welding, and machining are carried out under close supervision with in-process checks for accuracy.

- Finishing: Each component is cleaned, deburred, painted, or coated according to the specification.

- Inspection: Every part is measured, tested, and approved before dispatch.

- Delivery: Items are packed securely and shipped on schedule to the client’s location anywhere in India.

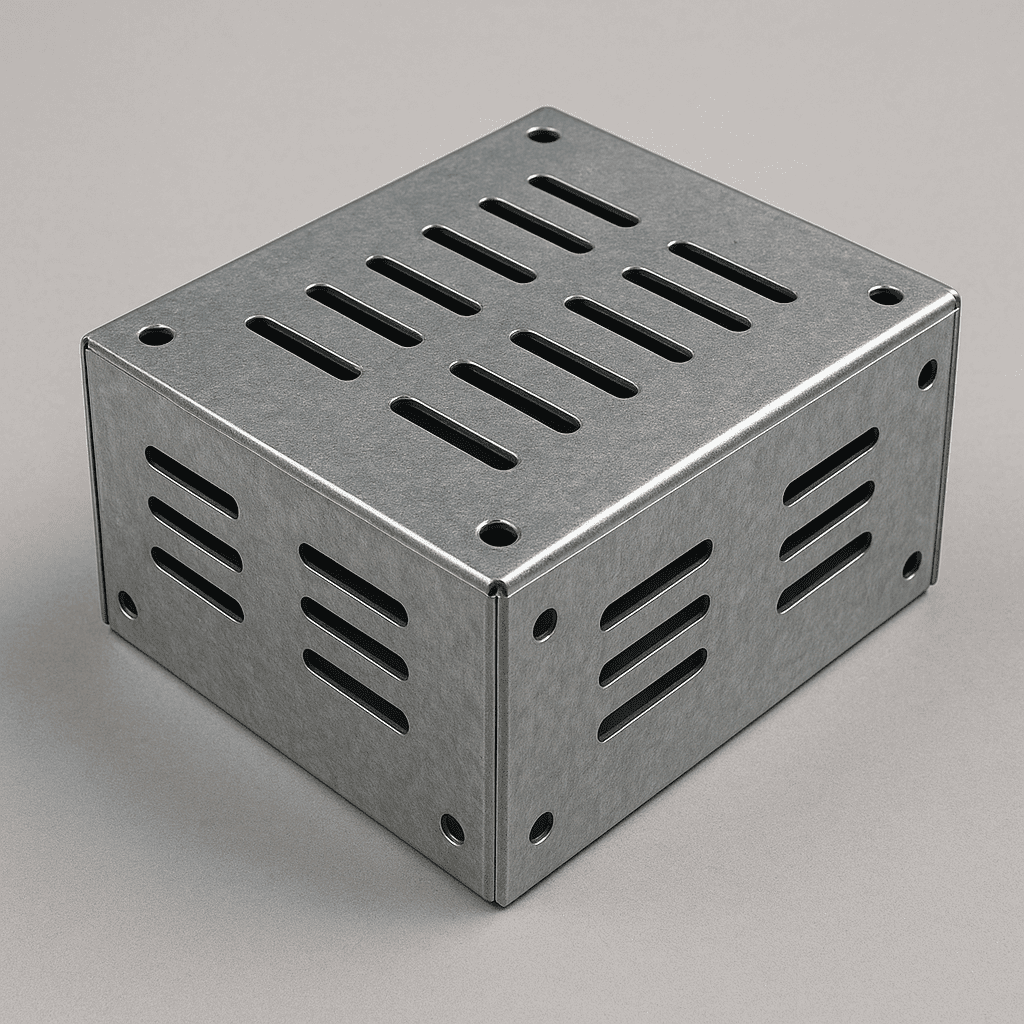

- Sheet metal fabrication work deals with thin metal sheets that are cut, bent, and assembled into precise shapes. It is widely used where lightweight and accuracy are important.

Common uses:

- Electrical panels and enclosures

- HVAC ducts and cabinets

- Panels, brackets, and covers

Many companies can cut and weld metal, but what makes Cyclotron Industries stand out is the way each project is managed. Every assignment is handled with care, clear communication, and a sense of shared responsibility.

- Precision that Speaks for Itself: All jobs are completed with tight tolerances and consistent quality. Each part is checked so that accuracy is maintained across batches.

- Capability for Any Scale: Cyclotron takes on single-piece jobs as well as large production runs. The same focus on quality and delivery applies to every order.

- Strong Local Advantage: Being based in Pune allows easy access to materials, coatings, and finishing services. This helps in faster completion and better coordination.

- Clear Communication: Clients get regular updates during the project. This helps them stay informed of the work progress and make changes if needed.

- Ongoing Support: The relationship does not end when the delivery is made. The team remains available for small adjustments, repeat orders, or future requirements.

Each project is seen as a partnership. The goal is not just to complete a job but to build long-term trust through consistent performance.

Blogs by Cyclotron Industries

Heavy fabrication plays a vital role in modern manufacturing, especially in industries that depend on large, strong, and long-lasting metal structures.

Everything about how ai for improving laser cutting is used worldwide. Iot and ai have been transforming the metal cutting industry and it’s trends.

Metal fabrication transforms raw metal into functional, dependable products through a structured sequence of processes

Fabrication work hsn code is 9988 with a GST Rate of 18% in India under the name of General fabrication work. Sheet metal, SS or aluminium fabrication HSN code

Welding simply means the process of joining two metals together whereas fabrication involves the complete cycle right from cutting, bending, alignment, welding and inspection, etc

All the common welding techniques in heavy fabrication includes MIG, TIG, SAW, SMAW, etc. Details about them are mentioned in this blog