Base frame fabrication

Base frame fabrication

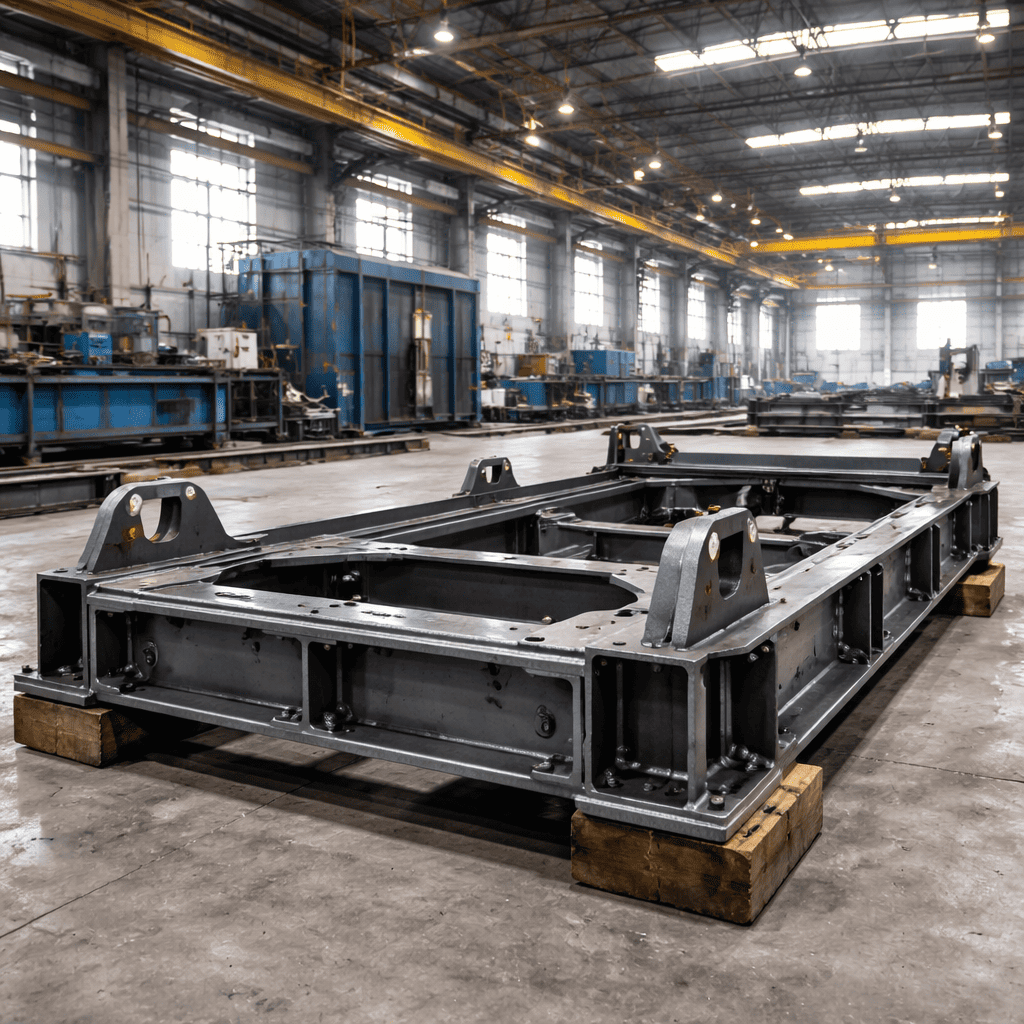

Heavy Metal Base frame fabrication in Pune, India by Cyclotron Industries. We deliver industry-grade and heavy-duty fabricated base frames depending on the specialized requirements.

We specialize in custom fabrication of high-load base frames used in pumps, machinery, generators, and skid-mounted industry systems.

By combining rich experience in heavy fabrication, industry-leading talent, and Pune’s established ecosystem, we deliver durable and high-precision base frames built to perform long, even under harsh industrial environments.

Leading Heavy Metal Base Frame Manufacturer in Pune

As a trusted heavy metal base frame manufacturer Pune, we provide standard and custom base frames for industrial equipment. Leveraging Pune’s strong manufacturing ecosystem and our fabrication expertise, we deliver high-quality base frames that meet demanding load, alignment, and vibration requirements with consistent quality and timely execution.

With years of experience serving diverse industrial clients, we design and fabricate heavy-metal base frames that meet strict load conditions, alignment, and vibration requirements.

Best Metal base frame fabrication services by Cyclotron Industries. We offer high precision, fast and accurate fabrication solutions for any kind of metal applications

What Is a Heavy Metal Base Frame?

Alignment & stability: Well-designed machine base frames ensure precise alignment between pumps, motors, and couplings. This results in smooth operation and reduces maintenance issues.

A heavy metal base frame is a rigid, load-bearing structural foundation made to support heavy industrial equipment, such as pumps, motors, compressors, generators, and complete skid-mounted systems. Not like the light fabrication structures, a heavy metal base frame is engineered with thick plates, structural steel sections, and reinforced welds to withstand high static loads, dynamic forces, and continuous industrial operation.

Role in Industrial Applications

Understanding the role of a heavy metal machine base frame is crucial for the performance and longevity of base frames.

- Load-bearing purpose: Heavy metal base frames securely carry the weight of machines and equipment, without deflection, sagging, or foundation failure.

Vibration control: The mass and rigidity of an industrial base frame help absorb and dampen vibrations from rotating machinery, reducing wear, noise, and fatigue failures.

Materials Used for Heavy Metal Base Frames

Choosing the right material plays a critical role in the performance, longevity, and durability of heavy metal base frames. It directly affects load capability, vibration behavior, corrosion resistance, and also the overall cost. Here are the most popular materials we use for the manufacturing of heavy metal base frames:

- Mild Steel (MS) Heavy Base Frames

Mild Steel is one of the most commonly chosen materials for industrial base frames for its strength, weldability, and cost-effectiveness.

- MS heavy base frames are built with IS 2062 and equivalent structural grades.

- They come with a high load capacity to handle heavy machinery.

- MS heavy base frames exhibit excellent weldability for rigid, reinforced structures.

- Also, this material offers a cost-effective solution for most industrial environments.

Applications of MS heavy metal base frames:

- Pumps and motor base frames

- Heavy-duty machine base frames

- Skid and package base frames

- Generators

In short, MS heavy base frames are used when strength, rigidity, and dimensional stability are important, but when there is no exposure to corrosive conditions.

2. Stainless Steel (SS) Base Frames

Stainless Steel is chosen when corrosion resistance, a clean appearance, and chemical compatibility are important.

- The SS base frame has excellent resistance to corrosion, moisture, and chemicals.

- It can be used in harsh and aggressive environments.

- The SS base frames offer long service life with minimal maintenance.

Applications:

- Water treatment and RO skid frames

- Chemical processing plants

- Outdoor or coastal installations

- Food, pharmaceutical, and cleanroom machinery

In short, the SS base frames are preferred when environmental durability is more important than material cost.

3. Cast Iron & Structural Steel Frames

Cast iron has high damping capacity, and the structural steel frames are used in specialized industrial requirements.

- These base frames have high mass and rigidity for vibration damping.

- Offers excellent performance under static and dynamic loads

- The structural steel frames provide superior stiffness for large systems.

Applications

- High-vibration machinery

- Large rotation equipment

- Precision machines requiring vibration isolation

The cast iron and structural steel frames are used when vibration control, stability, and load resistance are critical to equipment performance.

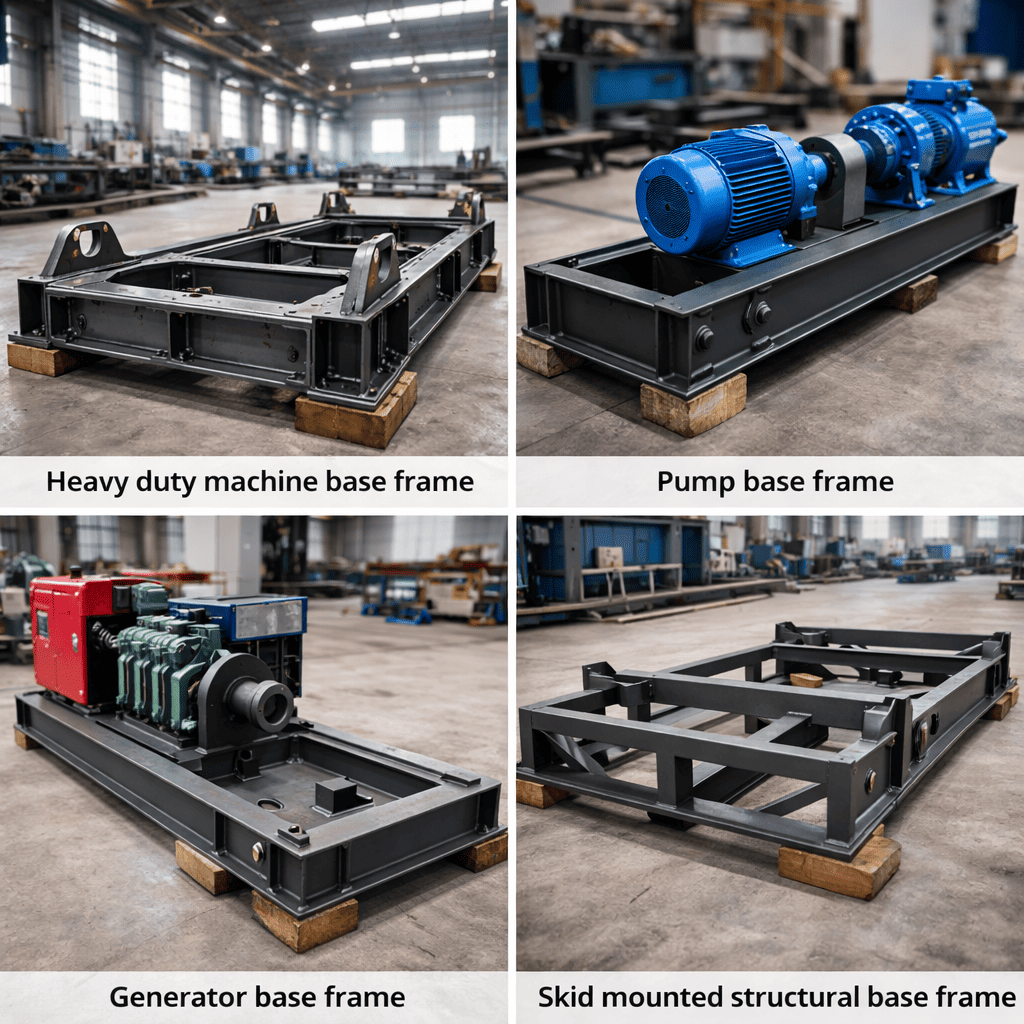

Types of Heavy Metal Base Frames We Manufacture

We manufacture a complete range of heavy metal base frames designed to support high-load industrial equipment and system-level installations. Each base frame is built for strength, rigidity, and long-term reliability in demanding operating conditions.

1.Heavy Duty Machine Base Frames

Our heavy duty machine base frames are designed for machines that require high structural strength and precise dimensional stability.

Applications include:

- CNC machines

- Special Purpose Machines (SPMs)

- Industrial and production equipment

These machine based frames provide uniform load distribution, vibration resistance, and stable machine performance during continuous operation.

2. Pump, Motor & Compressor Base Frames

We manufacture precision-engineered pump base frames and motor base frames for rotating and fluid-handling equipment.

Types include:

- Pump base frame

- Motor base frame

- Motor pump base frame

- Centrifugal pump base frame

- Compressor base frame

- Pump trolley base frame

These base frames ensure proper shaft alignment, reduced vibration, and reliable operation under dynamic loads.

3.Generator & Genset Base Frames

Our generator base frames are fabricated to handle vibration, impact loads, and continuous power-generation conditions.

Manufactured solutions include:

- Generator base frame

- Diesel generator base frame

- MS genset base frame

These genset base frames provide a stable and durable foundation for power generation equipment.

4.Skid-Mounted & Structural Base Frames

We fabricate skid-mounted and structural base frames for modular and packaged industrial systems.

Applications include:

- Skid base frame and fabricated skid frame

- RO skid frame for water treatment systems

- CNG package base frame

- Container-based frame for packaged systems

- Structural base frames for system-level installations

These base frames simplify transportation, installation, and site integration while ensuring structural strength and durability.

Best Metal base frame fabrication services by Cyclotron Industries. We offer high precision, fast and accurate fabrication solutions for any kind of metal applications

Heavy Metal Base Frame Fabrication Capabilities

Being an expert provider of base fabrication Pune, Cyclotron Industries offers end-to-end heavy fabrication capabilities for manufacturing robust heavy metal base frames. Our fabrication process is carefully structured to meet the industrial loading requirements, precision alignment, and performance expectations in the long term. Our fabrication capabilities include:

1.Welding Processes (MIG / ARC)

We use MIG and ARC welding based on material grade, thickness, and load conditions to achieve strong joints, deep penetration, and consistent weld quality across the base frame.

2. Machining & Leveling

Critical mounting surfaces undergo machining and precision leveling to ensure flatness, dimensional accuracy, and proper alignment of pumps, generators, and other equipment, reducing vibration and operational stress.

3. Stress Relieving (If Applicable)

For large, high-load, or vibration-sensitive base frames, stress relieving is performed to minimize residual welding stresses and improve dimensional stability and long-term reliability.

4. Surface Finishing (Painting & Coating)

To protect against corrosion and environmental exposure, we provide industrial painting, anti-corrosion coatings, and application-specific finishes, making the base frames suitable for both indoor and outdoor use.

By integrating welding, machining, stress relieving, and surface finishing, we deliver heavy metal base frames built for demanding industrial applications.

Industries We Serve

We serve heavy metal base frames across a range of industries, including:

- Manufacturing & Automation

- Pumps & Fluid Handling

- Power Generation

- Oil & Gas

- Water Treatment & RO Plants

- Heavy Engineering

Why Choose Us as Your Heavy Metal Base Frame Manufacturer in Pune?

The choice of a heavy metal base manufacturer directly impacts the equipment performance, life span, and installation accuracy. At Cyclotron Industries, we bring in engineering expertise with advanced heavy fabrication capabilities to deliver heavy metal base frames that perform well under demanding industrial conditions. Some of the reasons why you should choose us:

- Custom design & fabrication: Fully customized base frames manufactured as per drawings, load conditions, and application needs.

- High load capacity frames: Built using industry-grade materials and reinforced fabrication to handle high static and dynamic loads.

- Precision alignment: Controlled fabrication, machining, and inspections ensure accurate alignment, reduced vibration, and lower maintenance.

- Worldwide supply: Fast local delivery in Pune, PAN-India logistics, and export-ready packaging for international supply.

- Pune-based manufacturing advantage: Access to skilled manpower, strong supply chains, and robust engineering infrastructure ensures consistent quality and quick turnaround.

Custom Heavy Metal Base Frame Design & Manufacturing

We are a trusted custom heavy metal base frame manufacturer, delivering heavy-duty base frames engineered for demanding industrial applications with a focus on strength, accuracy, and long-term performance.

1.Drawing-to-Manufacturing Expertise

We manage the complete drawing-to-manufacturing cycle, converting fabrication drawings, GA layouts, or concepts into manufacturable designs through proper section selection, detailing, and process planning.

2.Load Calculations & Engineering Validation

Each base frame is engineered using detailed static and dynamic load calculations to control deflection, maintain alignment, and ensure reliable performance throughout its service life.

3. Client-Specific Dimensions

Base frames are manufactured to client-specific dimensions, including mounting slots and leveling arrangements, ensuring accurate fitment and reduced installation time.

4. Compliance & Tolerances

All fabrication follows defined industrial standards and tolerances, with machining, leveling, and inspection checks to ensure flatness, alignment accuracy, and weld quality.

Best Metal base frame fabrication services by Cyclotron Industries. We offer high precision, fast and accurate fabrication solutions for any kind of metal applications

Cyclotron group clients

Frequently Asked Questions

1.What is the load capacity of a heavy metal base frame?

Load capacity is the maximum load the heavy metal base frame can carry without any deformation or failure. The load capacity depends on several factors, such as material grade, frame size, structural design, and operating conditions. Considering their operating conditions, the heavy metal base frames are engineered to easily handle static and high dynamic loads varying from several tonnes upward with appropriate safety factors built into the design.

2. Do you manufacture custom machine base frames?

Yes. At Cyclotron Industries, we specialize in building custom metal base frames in-house. Each base is carefully designed and fabricated to your drawings and custom requirements, including load capacity, mounting details, and alignment tolerances.

3. What is the price of heavy metal base frames in Pune?

The price of heavy metal base frames in Pune depends on several factors like strength and material requirements, fabrication complexity, machining requirements, surface finishing, and more. For a custom quote, we recommend getting in touch with us and sharing your drawing details and other specifications.

4. Do you supply base frames across India?

Yes. We supply heavy metal base frames across India and also support export requirements. With PAN-India logistics, we carefully package and transport the frames to ensure safe delivery to industries nationwide.

5. Which material is best for heavy-duty base frames?

The right material depends on the load capacity, working conditions, and strength requirements. Mild Steel (IS 2062) is one of the widely used materials for the manufacture of heavy-duty base frames for its exceptional strength and cost-effectiveness. Stainless Steel is preferred in corrosion environments. The cast iron and structural steel are preferred for cases involving damping and high vibration applications.

Blogs by Cyclotron Industries

Heavy fabrication plays a vital role in modern manufacturing, especially in industries that depend on large, strong, and long-lasting metal structures.

Everything about how ai for improving laser cutting is used worldwide. Iot and ai have been transforming the metal cutting industry and it’s trends.

Metal fabrication transforms raw metal into functional, dependable products through a structured sequence of processes

Fabrication work hsn code is 9988 with a GST Rate of 18% in India under the name of General fabrication work. Sheet metal, SS or aluminium fabrication HSN code

Welding simply means the process of joining two metals together whereas fabrication involves the complete cycle right from cutting, bending, alignment, welding and inspection, etc

All the common welding techniques in heavy fabrication includes MIG, TIG, SAW, SMAW, etc. Details about them are mentioned in this blog