What is metal fabrication ?

What is metal fabrication ?

- Metal fabrication transforms raw metal into functional, dependable products through a structured sequence of processes

- Metal fabrication involves a set of planned steps starting from cutting, forming, welding, finishing and assembly, all done to meet a specific design and engineering needs.

- Metal fabrication is a key part of building the world we live in. It’s found in bridges, roads, factories, vehicles, machines, and many everyday items, even if we don’t always see it

- In simple terms, metal fabrication means turning raw metal like sheets, plates, pipes, or bars into strong, useful parts

Best fabrication services by Cyclotron Industries. We offer high precision, fast and accurate fabrication solutions for any kind of metal applications

Fabrication vs Welding vs Machining vs Casting

- These terms often get used interchangeably, but on the shop floor, they mean very different things.

- Metal fabrication covers the whole process of making a metal part or structure from raw material. This can include cutting, bending, forming, welding, machining, surface finishing, and final assembly. In short, fabrication is about turning an idea or drawing into a finished, usable part.

- Welding is one part of fabrication. Its main job is to join two or more metal pieces together. While a weld can be a crucial part of a component, welding alone doesn’t make the whole product. It’s just one step in a bigger process.

- Machining means removing material from metal to get the exact size and shape needed. This is how holes are drilled, threads are made, slots are cut, and tight tolerances are reached. Machining is used when accuracy is more important than speed, or when parts need to fit together perfectly.

- Casting is a different process. Here, metal is melted and poured into a mold. As it cools and hardens, it takes the shape of the mold. Casting is often used for parts with complex shapes that are hard or costly to make by cutting or fabrication.

- Simply put, fabrication is the main process, welding and machining are part of it, and casting is a different method.

| Aspect | Fabrication | Welding | Machining | Casting |

|---|---|---|---|---|

| Definition | Complete process of converting raw metal into a finished part or structure | Process of joining two or more metal parts together | Material removal process to achieve precise size and shape | Molten metal poured into a mould to form a part |

| Role in Manufacturing | Main end-to-end process | A single step within fabrication | Often a precision step within fabrication | Independent manufacturing method |

| Primary Objective | Create a complete usable component or structure | Permanent joining of metal parts | Achieve tight tolerances and accuracy | Create complex shapes economically |

| Processes Involved | Cutting, bending, forming, welding, machining, finishing, assembly | MIG, TIG, ARC, Laser welding, etc. | Drilling, milling, turning, threading, slotting | Melting, moulding, cooling, finishing |

| Accuracy Level | Moderate to high (depends on included machining) | Low to moderate | Very high (tight tolerances) | Moderate (post-machining often required) |

| Complex Geometry | Good flexibility | Limited to joint design | Limited by tool access | Excellent for complex shapes |

| Typical Use Cases | Frames, enclosures, platforms, structures | Assemblies, joints, structural connections | Precision components, mating parts | Engine blocks, housings, complex parts |

| Cost Efficiency | Best for custom and mid-volume production | Low cost per joint | Higher cost due to precision | Cost-effective at high volumes |

| Relationship | Main manufacturing workflow | Subset of fabrication | Subset of fabrication | Alternative to fabrication |

Types of Parts Made Through Fabrication

Metal fabrication produces a wide variety of components, from small brackets and enclosures to large structural frames and industrial equipment.

- Structural frames and beams

- Sheet-metal enclosures and cabinets

- Industrial machine parts

- Platforms, staircases, railings

- Automotive and aerospace components

Depending on the project, metal fabrication work may involve single custom pieces or large batches for repeated use in manufacturing.

Metal fabrication process

1. Cutting Processes

Cutting is the first and most critical step in metal fabrication. It defines the basic shape of the component and has a direct impact on accuracy, material usage, and overall quality. Different cutting methods are used based on the metal type, thickness, design complexity, and production volume. In metal fabrication work, selecting the right cutting process helps balance precision, speed, and cost.

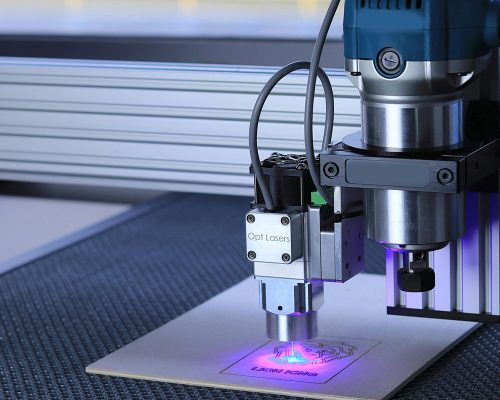

2. Laser Cutting

Laser cutting uses a high-focused laser beam to melt and cut metal with high precision. It is commonly used for thin to medium thickness sheets where accuracy and clean edges are required, such as panels, enclosures, and precision components.

Benefits:

- High-dimensional accuracy suitable for tight tolerances

- Clean and smooth cut edges with minimal burrs

- Ideal for complex shapes, fine details, and small holes

- Excellent repeatability for batch and OEM production

- Minimal material wastage due to narrow kerf width

Limitations:

- Higher machine and operating costs

- Reduced efficiency on very thick metal plates

- Reflective materials may require special settings or equipment

- Not always economical for heavy structural fabrication

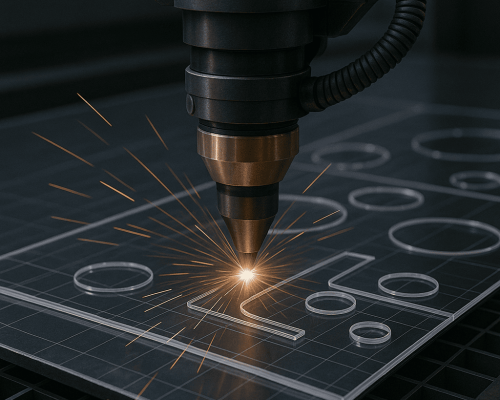

3. Plasma Cutting

Plasma cutting uses a high-temperature plasma arc to cut through electrically conductive metals. It is typically used for thicker materials where speed is more important than ultra-fine precision. Plasma cutting is common in heavy metal fabrication, structural work, and industrial fabrication jobs. The process is faster and more economical for thick plates, but the cut edges are rougher compared to laser cutting and may require additional finishing.

Benefits:

- Fast cutting speeds for thick metal plates

- Lower equipment cost compared to laser cutting

- Suitable for structural steel and heavy fabrication work

- Effective for large parts where fine detail is not critical

Limitations:

- Rougher edge finish compared to laser cutting

- Larger heat-affected zone, which can cause distortion

- Lower precision for detailed or intricate designs

- Often requires secondary finishing operations

4. Waterjet Cutting

In this type of cutting, a high-pressure stream of water, often mixed with abrasive material, is used to cut metal. It is chosen when heat must be avoided, as the process does not create a heat-affected zone. This makes it suitable for sensitive materials, thick sections, and applications where material properties must remain unchanged.

Benefits:

- No heat-affected zone, preserving material strength

- Can cut very thick materials with consistent quality

- Capable of complex shapes and tight tolerances

Limitations:

- The cutting speeds are lower compared to laser and plasma cutting

- Higher operating and maintenance costs

- Abrasive usage increases overall job cost

- Less suitable for high-volume production

5. Saw Cutting

Saw cutting is widely used for cutting metal bars, pipes, tubes, and structural sections. It is commonly applied in preparation stages before further fabrication or machining.

Benefits:

- Simple and reliable method for cutting long sections

- Cost-effective for standard profiles and materials

- Suitable for a wide range of bar and tube sizes

- Commonly used in the preparation stages of fabrication

Limitations:

- Lower accuracy compared to laser or waterjet cutting

- Slower cutting speeds for hard or thick materials

- Limited capability for complex or angled cuts

- Additional machining may be required for tight tolerances

In metal fabrication processes, no single cutting method is ideal for every application. The right choice depends on material type, thickness, accuracy requirements, and production scale. Experienced fabricators carefully select the cutting process to balance quality, cost, and efficiency, whether for custom work or large-scale fabrication projects.

6. Forming & Bending

Forming and bending are the stages where flat or straight metal starts to take its final shape. Instead of cutting material away, these processes reshape the metal into three-dimensional forms. This step adds strength, structure, and function to a component, which is why it carries as much weight as cutting in fabrication work. If forming is not done accurately, parts will struggle to line up during assembly and may not perform as intended once they are in use.

7. Press Brake Bending

Press brake bending is one of the most commonly used forming methods in metal fabrication. It works by pressing a sheet of metal between a punch and a die to create precise bends at specific angles.

Where it is used

- Enclosures, brackets, panels, and frames

- Sheet metal parts that need sharp or well-defined bends

Key points

- Works across a wide range of material thicknesses

- Allows good control over bend angles

- Commonly used for both one-off custom work and batch production.

8. Rolling

Rolling forms metal into curved shapes by passing it through a set of rollers. It is typically used to create cylinders, cones, and large-radius curves.

Applications:

- Tanks, pipes, curved panels, and structural sections

- Components with smooth, continuous curves

Key Points:

- Ideal for large or uniform curves

- Works well with plates and thicker materials

- Requires careful setup to maintain consistent curvature

9. Folding

Folding bends sheet metal using a clamping beam and a folding blade. It is commonly used for straight bends along the edge of a sheet.

Applications:

- Panels, boxes, and simple sheet metal parts

- Light to medium thickness sheets

Key Points:

- Produces clean bends with minimal marking

- Faster for simple shapes

- Limited in handling very thick materials

10. Stamping

Stamping uses dies and presses to shape metal at high speed. It is mainly used in mass production.

Applications:

- Automotive parts, electrical components, fittings

- High-volume metal fabrication job work

Key Points:

- Very efficient for large quantities

- High repeatability and consistency

- High initial tooling cost

11. Deep Drawing

Deep drawing is a specialized forming process where a flat sheet is drawn into a die to create deep, hollow shapes.

Applications:

- Containers, housings, and cylindrical components

- Products requiring seamless shapes

Key Points:

- Produces strong, uniform parts

- Requires careful control of material flow

- Best suited for ductile materials

Best fabrication services by Cyclotron Industries. We offer high precision, fast and accurate fabrication solutions for any kind of metal applications

Importance of Tolerances and Material Thickness

Tolerances and material thickness are critical during the process of forming and bending. Thicker plates need more force and wider bend radii.

Thinner sheets can easily distort or crack if they are not handled carefully. Even small changes in thickness can shift bend angles and final sizes.

When tolerances are maintained properly, parts fit better during welding and assembly. Rework is reduced. Overall product quality improves

In professional fabrication, forming is not only about getting the shape right. It is also about consistency, strength, and how the part performs over time.

Once cutting, forming, and bending are done, metal components usually reach their basic shape. But in many fabrication jobs, shape alone is not enough. This is where machining comes in.

Machining adds accuracy and functional detail so parts meet exact design needs. Machining in metal fabrication removes small amounts of material to achieve precise dimensions and clean features. Machining is carried out once cutting or forming is done. It becomes important when parts must fit well, take fasteners, or match up with other components.

Processes in Metal fabrication

Milling: Milling removes metal using rotating cutting tools. It is used when flat surfaces or defined shapes are needed on a part. This process works for both simple cuts and more detailed profiles. Milling is used for flat faces, grooves, keyways, and parts where dimensions need to stay controlled. It is especially helpful when fabricated parts must sit flush or match properly during assembly.

Drilling: Drilling is done to create round holes in metal parts. It is one of the most common machining operations used in fabrication work. Drilling is typically used for bolt holes, fastener locations, and openings for wiring or piping. It is also done before tapping or reaming. When drilling is accurate, parts line up better during assembly and maintain strength in the final build

Turning: Turning is done on a lathe, where the part rotates while a cutting tool shapes it. This process is mainly used for round or cylindrical components such as shafts, pins, and bushings. It is chosen when parts need proper concentricity and a smooth surface finish. Turning is often used along with fabrication when round parts are part of a larger assembly.

Tapping: Tapping is used to create internal threads inside drilled holes. This allows bolts or screws to be fastened directly into the metal. It is commonly used in plates, brackets, and frames where using nuts is not practical. The tapping process makes assembly faster and avoids the need for additional hardware.

Welding in Metal fabrication

Welding is the most common joining method in metal fabrication. It permanently fuses metal parts together using heat and, in some cases, filler material. Different welding techniques are chosen based on material type, thickness, strength requirements, and production volume.

- MIG Welding

MIG welding is reputed for its speed and ease of operation. It is suitable for mild steel, stainless steel, and aluminum and is commonly used in general fabrication and production work. - TIG Welding

TIG welding offers greater control and produces clean, high-quality welds. It is preferred for thin materials, critical components, and applications where appearance and precision matter. - Stick Welding

Stick welding is robust and versatile, making it suitable for heavy fabrication, outdoor work, and thick materials. It is often used where conditions are less controlled. - Robotic Welding

Robotic welding is used in high-volume and repetitive fabrication jobs. It delivers consistent weld quality, improves productivity, and reduces human error, making it ideal for OEM and industrial production.

- MIG Welding

FAQs

1. Is welding the same as metal fabrication?

No. Welding is only one part of metal fabrication. Fabrication covers the full process, starting from raw material and ending with a finished product. That includes cutting, forming, machining, welding, finishing, and final assembly. Welding is used to join metal parts together, but by itself, it does not complete a fabricated component.

2. Which metals are easiest to fabricate?

Mild steel and aluminum are generally easier to fabricate compared to other metals. Mild steel is widely used because it is affordable and responds well to cutting, bending, and welding. Aluminum is lightweight and machines easily, though it needs the right welding techniques. In practice, ease of fabrication also depends on material thickness, part design, and the tolerances required.

3. What affects the cost of fabrication?

There isn’t one fixed cost for fabrication. It depends on the job. The type of metal, how thick it is, and how complex the design needs to be all matter. Some parts go through more fabrication steps than others. Cutting, machining, labour time, surface finishing, and production quantity also affect pricing. If tolerances are very tight, the design is custom, or the delivery needs to be faster, the cost usually increases.

4. How does sheet metal fabrication differ from heavy fabrication?

Sheet metal fabrication is done on thinner material. It focuses more on details, Accuracy and bend quality. You see this kind of fabrication in panels, enclosures, and lighter components.

Heavy fabrication works with thick plates and large sections. It is used for structures and heavy equipment, where strength comes first. The machines and methods used are very different from sheet metal work.

Cyclotron group clients

Best fabrication services by Cyclotron Industries. We offer high precision, fast and accurate fabrication solutions for any kind of metal applications