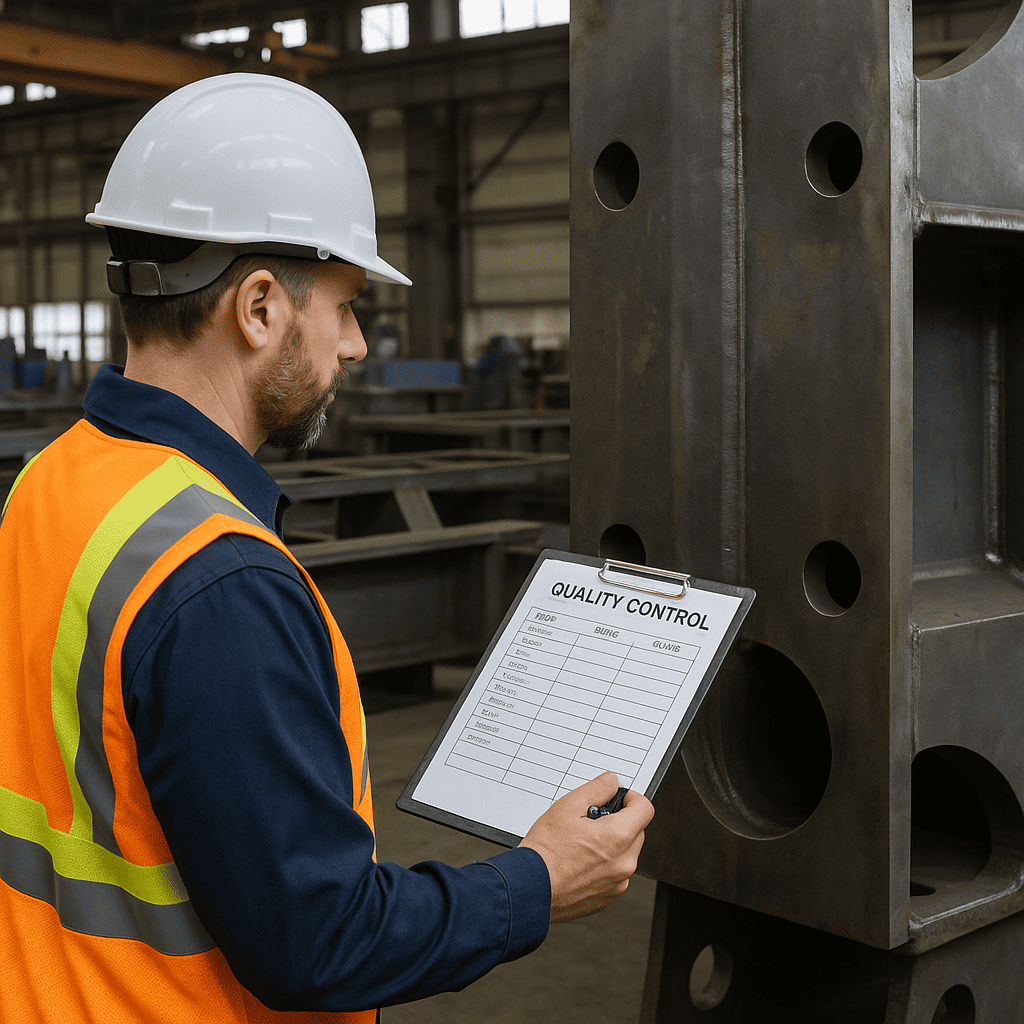

Quality control in heavy fabrication

Quality Control in heavy fabrication has become critical to ensure that the manufactured product meets customer requirements, global standards, and stringent regulatory guidelines.

Maintaining high fabrication quality, safety, and reliability is paramount in industries such as Aerospace, automotive, construction, and electronics.

This article discusses popular processes implemented across various industry sectors to improve quality in heavy fabrication.

Best fabrication services by Cyclotron Industries. We offer high precision, fast and accurate fabrication solutions for any kind of metal applications

Quality in heavy fabrication

Quality control in heavy fabrication is mandatory to minimize errors, reduce material wastage, and machine time.

Adherence to ASME, MWS, and ISO standards and the maintenance of consistent quality in fabricated components are crucial to avoid performance and safety issues. The importance of QC, reliability, and safety in large industrial structures is paramount for preventing failures and maintaining product integrity.

Well, a robust, well-documented quality control system can benefit industries by improving precision, transparency, and real-time updates.

Let’s dig this article a little deeper to understand the importance of quality control from the initial to the final phase of the product.

What is Quality Control in Heavy Fabrication?

- Quality control in heavy fabrication is a systematic yet unwavering process that ensures fabricated components meet required specifications, strength, and safety standards.

- Heavy fabrication quality relies on plate preparation, material integrity, weld technique, and dimensional accuracy.

- Negligence at any of these stages may lead to increased operational costs, catastrophic failure, and safety hazards.

- The major goal of quality control (QC) is to find errors or defects at key stages, fix them, and ensure customers receive fully functional fabricated components.

- An effective quality control approach not only helps maintain a company's reputation but also reduces delays and downtime and ensures regulatory compliance.

Key Areas of Quality Control

Quality control in heavy fabrication is a strategic process and requires a proper planning, procedure, a skilled workforce, and well-maintained equipment. This section is dedicated to quality control measures that are implemented to create a robust framework. Here are the six key stages involved in heavy fabrication quality control:

1. Material Inspection & Traceability

This key stage includes verifying the grade of raw material, certificates, and heat numbers to confirm if the supplier is following the defined quality standards. That’s why it is important to use correct alloys and thicknesses. Regular audits are conducted to detect deviations or errors in the finished products to ensure safety and compliance. In addition, a traceability system is employed to locate the defect to an exact location.

2.Welding Quality & Procedures

Welding is a critical foundation for heavy fabrication projects, providing structural integrity and reliability. It is imperative to have a welder who is not only well-trained but also holds the necessary qualifications and certifications, and who adheres to standards set by organizations such as the American Welding Society (AWS), Procedure Qualification Records (PQR), or the Indian Standard IS 9595.

These credentials indicate that the welder has a comprehensive understanding of the complexities involved in controlling heat input, achieving optimal penetration, and minimizing distortion during welding. Furthermore, it is important that the welding equipment employed is meticulously calibrated and fully operational, in strict compliance with the established Welding Procedure Specifications (WPS). This attention to detail in both training and equipment helps guarantee the production of high-quality welds that meet the industry standards and project specifications.

3. Dimensional Accuracy

Dimensional accuracy depends on various factors, including the selected material, mold design, pouring & cooling rates, post-casting finishing, etc. This key area focuses on dimensional checks per design specifications, critical interfaces, and tolerance checks after machining and assembly. The use of measuring instruments and precision jigs is essential to maintaining the high fabrication quality, structural integrity, and functionality of the manufactured product.

4. Non-Destructive Testing (NDT)

Non-destructive testing techniques such as UT, RT, PT, and MT are mandatory for validating manufactured parts for precision and dimensional accuracy. The testing includes performance under extreme conditions to verify tolerances, pressure, and stress levels. The NDT protocol helps identify internal and surface defects to confirm that the final product is safe, reliable, and ready for delivery.

5. Surface Preparation & Coating

This crucial stage focuses on inspecting the surface profile and the blasting equipment, Painting, and corrosion protection. It also involves measuring coating thickness (wet film thickness) and cleanliness level, as per ISO 8501 or SSPC standards. Salt or dust testing, such as the adhesive tape method, is also conducted to ensure no residues remain on the surface. Final testing confirms whether the finished product meets the desired safety, performance, and quality parameters.

Best fabrication services by Cyclotron Industries. We offer high precision, fast and accurate fabrication solutions for any kind of metal applications

Standards & Certifications

Metal fabrication standards & certifications serve as benchmarks for heavy fabrication quality and consistency. Adherence to these standards not only provides quality assurance to customers but also ensures compliance with AWS, ASME, and ISO standards.

Here, we have discussed some common heavy fabrication standards and welding certifications that validate fabricators in creating code-compliant, globally quality components for different applications.

- NDT (non-destructive testing) includes UT/MT/PT for finding errors.

- Welding certifications such as SMAW, FCAW, and GTAW.

- Metal fabrication certifications from AISC or BIS, including training & education, followed by assessments to evaluate knowledge in QC/QA and WPS/WQT procedures.

- MTCs (material test certificates)

- Documentation and record keeping.

Best fabrication services by Cyclotron Industries. We offer high precision, fast and accurate fabrication solutions for any kind of metal applications

Role of Skilled Workforce & Inspection Team

A skilled workforce, such as certified welders, trained inspectors & QA personnel, plays a critical role in heavy fabrication quality checks.

Continuous training and process improvement are essential to achieving high precision, accuracy, consistency, and quality in manufactured components.

Only Skilled labor can detect errors at key stages and address them for immediate solution.

Whereas, the inspection team’s role is to verify the quality and thickness of the raw material, conduct dimensional checks, document, report errors, and perform in-process & final inspections, while adhering to customer specifications and standards.

Conclusion

Quality is a continuous process, not a one-time step. Strong quality control in heavy fabrication ensures safety, durability, and customer trust. In a nutshell, Customer satisfaction & success depend on the Inspection processes implemented in each stage of fabricated components. At Cyclotron Industries, we use ISO certified quality control procedures, certified welders, and years of fabrication experience to build highly reliable and durable components. We understand the fact that quality in heavy fabrication is non-negotiable. Looking for a reliable partner to elevate the safety, longevity, and performance of your projects’ critical components? Contact Cyclotron Industries today!

Cyclotron group clients

Best fabrication services by Cyclotron Industries. We offer high precision, fast and accurate fabrication solutions for any kind of metal applications