Aluminium Fabrication services in Pune

Best Aluminium Fabrication services in Pune by Cyclotron Industries . We offer high precision, fast and accurate aluminium fabrication solutions for all your needs

Aluminium fabrication services in Pune

At Cyclotron Industries, we take immense pride in being one of the fastest-growing names in aluminium fabrication services in Pune. Over the years, we have built a strong reputation through engineering precision, skilled workmanship, and reliable service.

Our team includes experienced engineers, technicians, and designers who work together to deliver practical and long-lasting fabrication solutions.

Using modern tools and advanced machinery, we create custom aluminium components that meet the requirements of different industries.

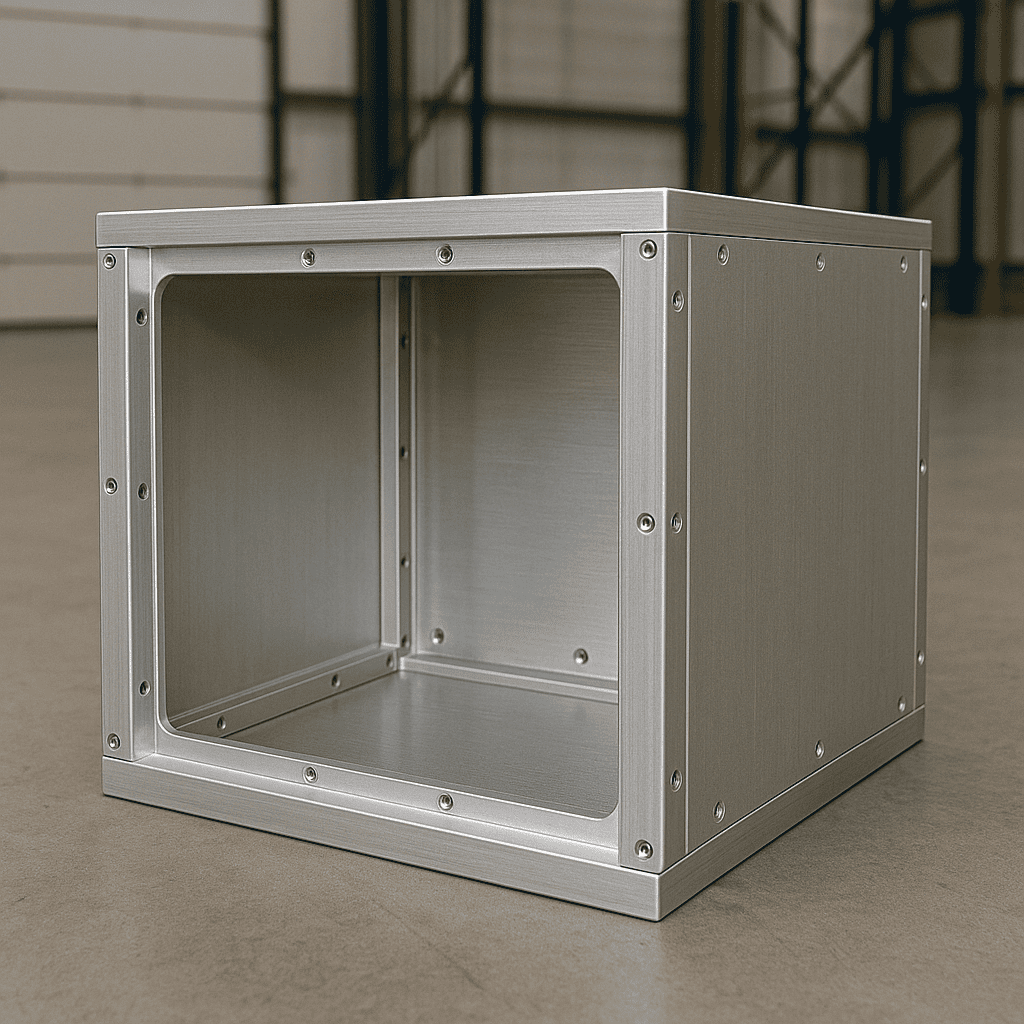

Whether it is a machine frame, protective enclosure, or a specialized aluminium structure, we focus on maintaining quality, accuracy, and timely delivery in every project.

Best fabrication services by Cyclotron Industries. We offer high precision, fast and accurate fabrication solutions for any kind of metal applications

Why Aluminium Fabrication?

Aluminium is one of the most preferred materials in fabrication because of its unique properties. It combines strength, low weight, and corrosion resistance, suitable for a diverse applications.

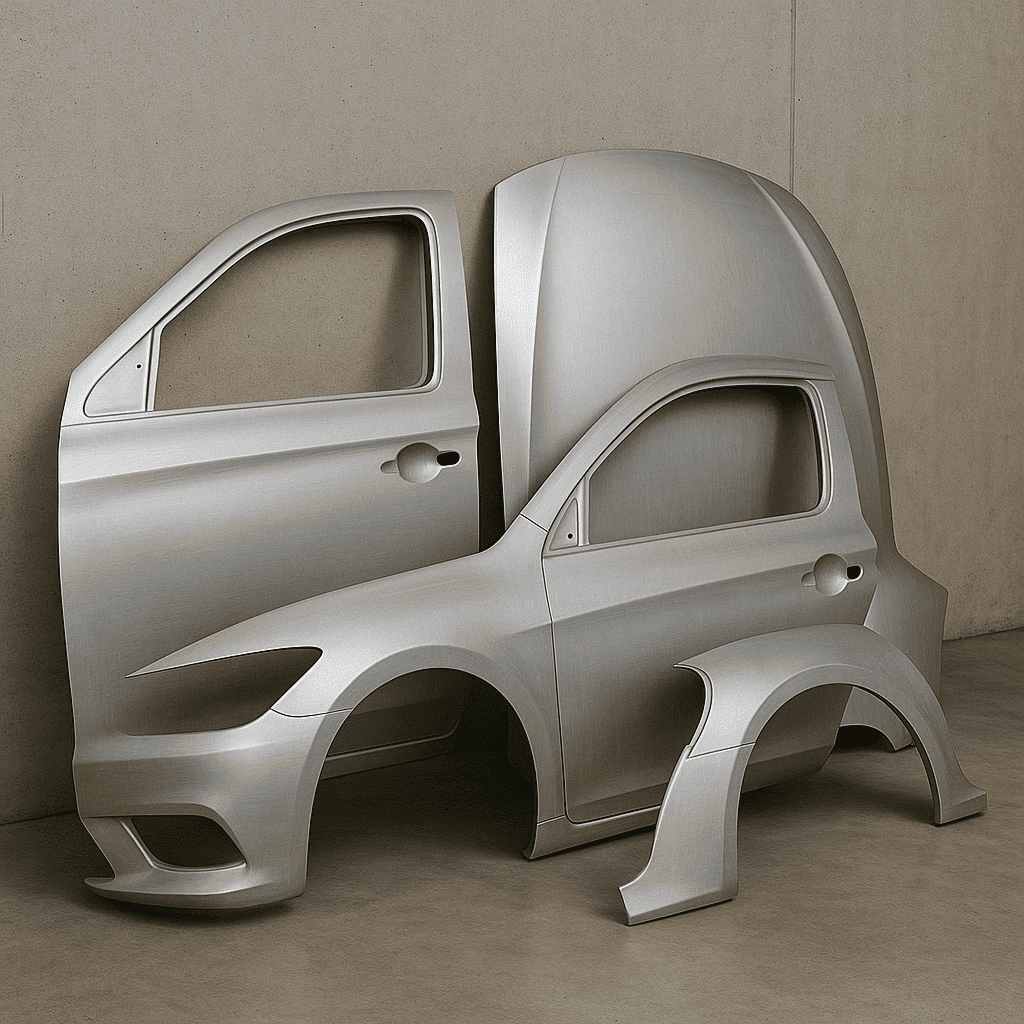

You can find aluminium in almost every major sector including automotive, electric vehicles, industrial machinery, electrical systems, construction, and even aerospace.

Key Advantages of Aluminium

1. High strength-to-weight ratio: Aluminium is strong yet lightweight, which makes it perfect for structures that need durability without adding extra weight.

2. Easy to handle and transport: Its lightweight nature reduces handling time and transportation costs.

3. Corrosion resistant: Aluminium naturally resists rust, corrosion, and daily wear, reducing frequent maintenance or replacements.

4. Built Tough: It holds up well in humid, coastal, or chemically exposed environments, making it ideal for both indoor and outdoor use.

5. Environmental-friendly: Aluminum is completely recyclable, making it a sustainable choice for eco-conscious manufacturers.

All these properties make aluminium a highly reliable and efficient material for fabrication projects. It provides the right mix of strength, adaptability, and longevity, which is why it continues to be the top choice for modern engineering applications.

Our Aluminium Fabrication Capabilities

- Cutting: We use CNC laser cutting, and plasma cutting machines for precise material cutting. The CNC programmed cutting ensures the bending angles are accurate and as per your design specifications.

- Bending and Forming: Our bending and forming setup can handle aluminium sheets of different thicknesses. We shape parts according to your technical drawings while keeping tight control over tolerances and repeatability.

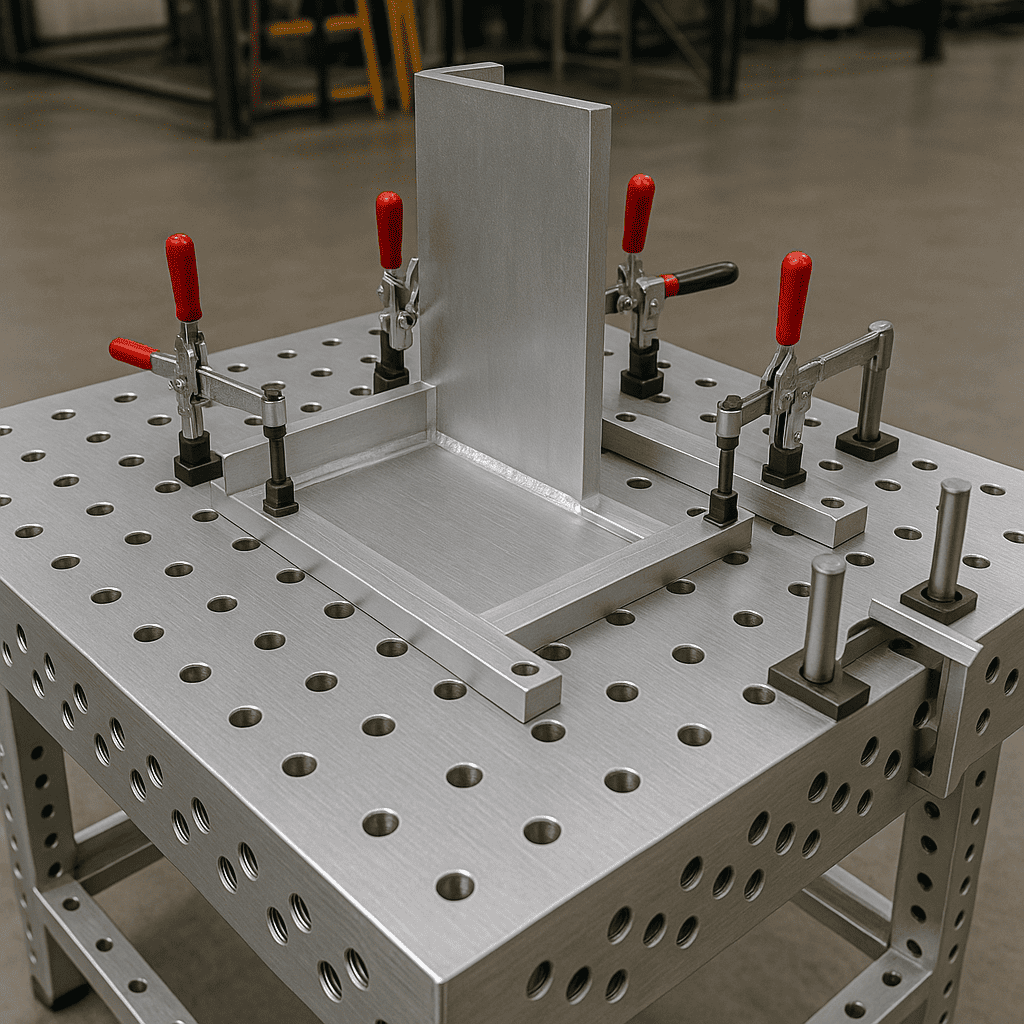

- Welding: With in-house modular welding tables and equipment, our technicians produce high-quality, uniform welds with good structural strength without affecting the surface finish.

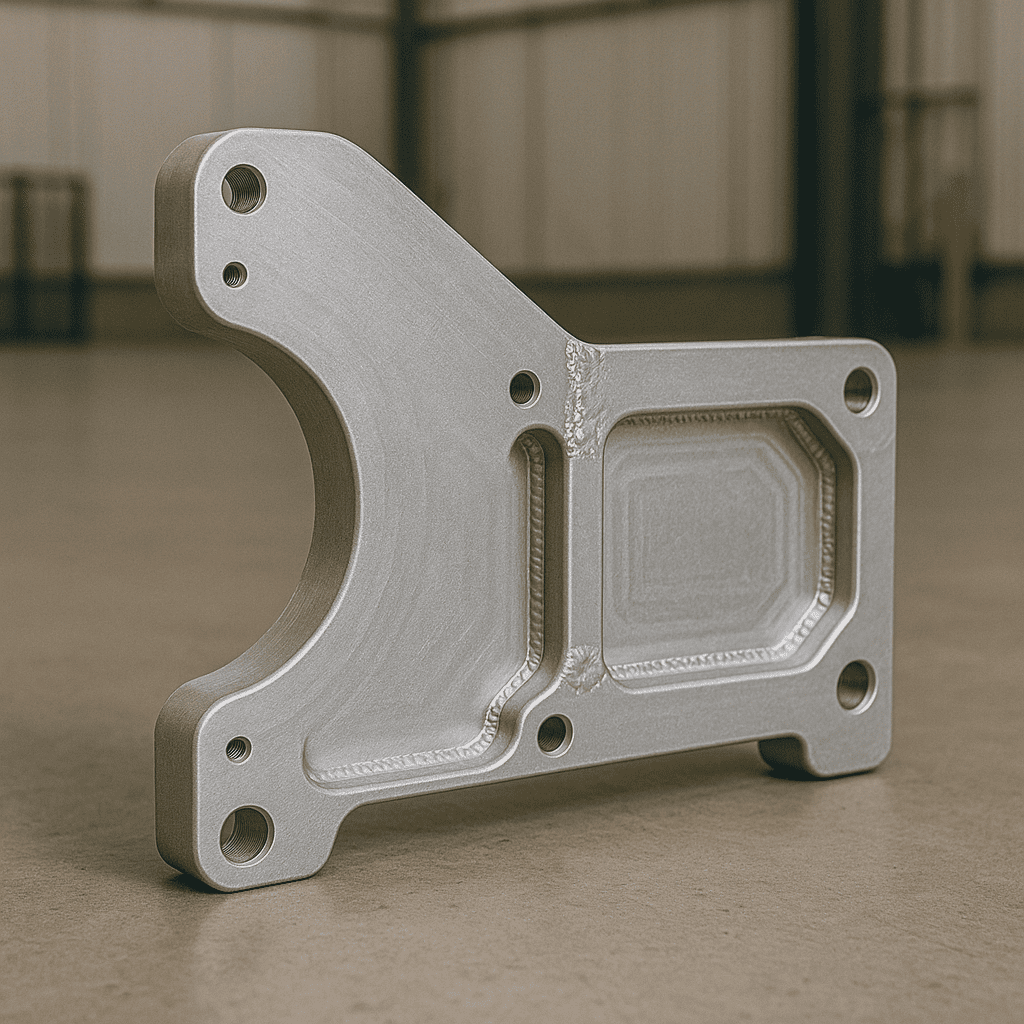

- Drilling and Tapping: Our machining stations offer precise drilling and tapping to match assembly requirements. Every hole and thread is aligned so that components fit together perfectly.

- Machining and Finishing: We perform CNC machining to refine edges, adjust tolerances, and prepare the parts for final assembly. Each fabricated component goes through finishing to ensure smoothness, functionality, and durability.

- Surface Treatment: To improve corrosion resistance and surface quality, we offer diverse finishing options as per your requirements: 1. Anodizing: Prevents corrosion and enhances surface protection 2. Powder coating: For an aesthetic appearance Polishing and brushing: To achieve a high-end, smooth finish.

Aluminium fabrication in Pune

Delivering the best Aluminium Fabrication Services in Pune, Cyclotron Industries works with a wide variety of aluminium fabricated products that cater to the needs of different industries. From small workshops to large OEMs, we deliver aluminium solutions that are precise, durable, and built to perform.

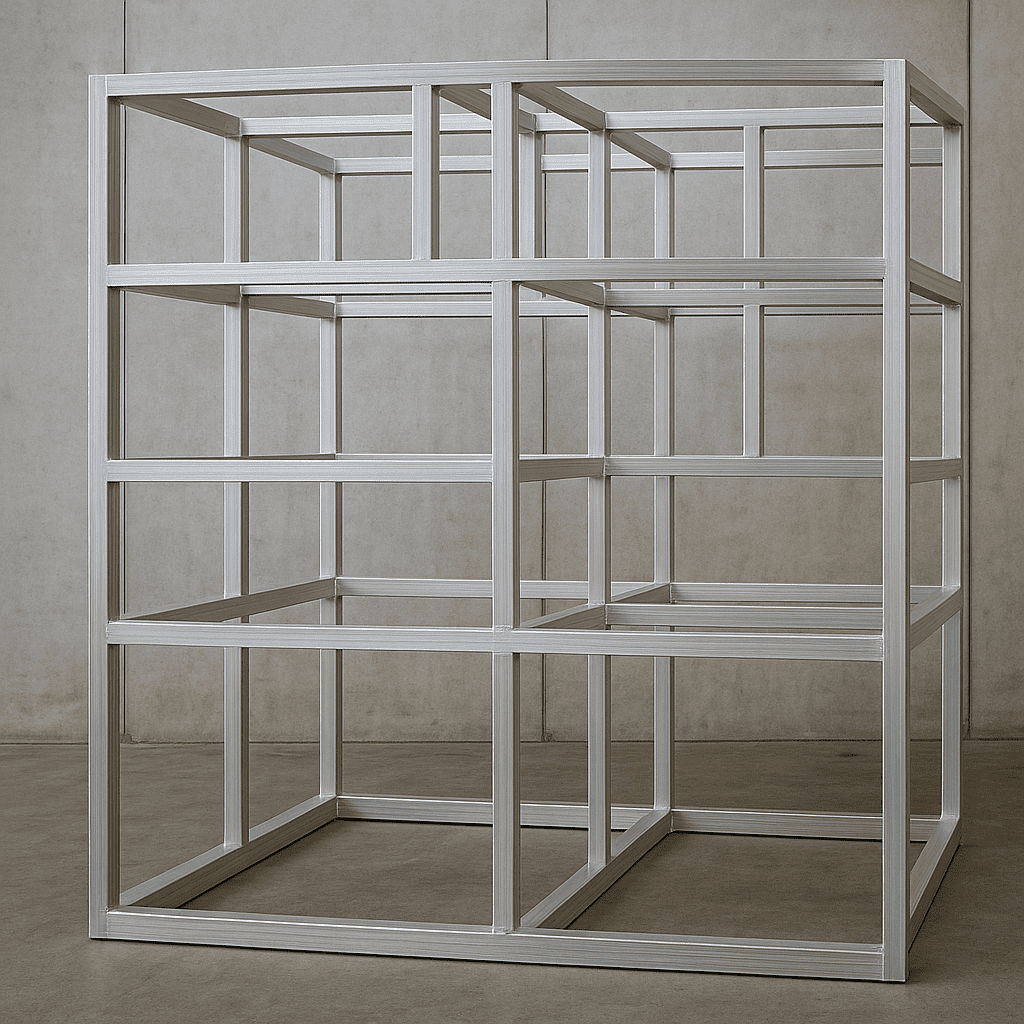

Aluminium frames and structures

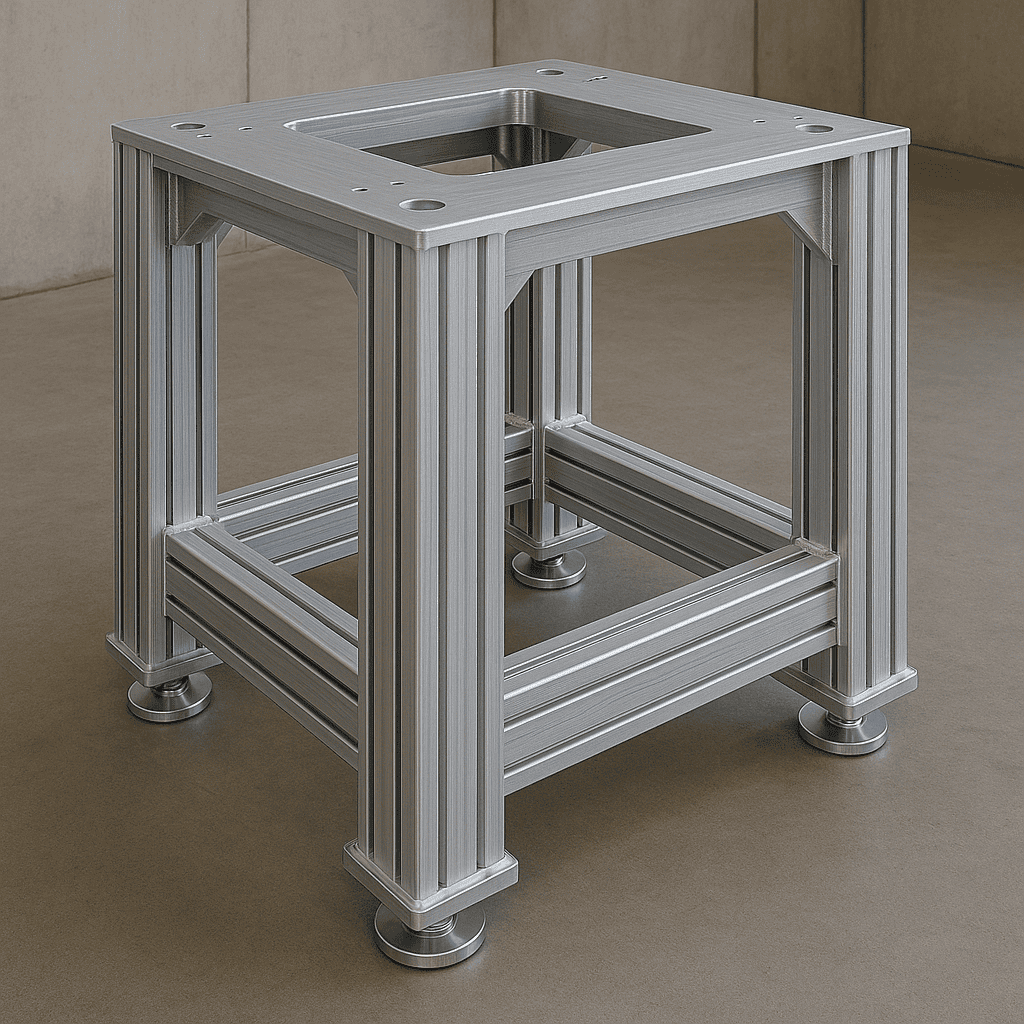

Machine bases and support structures

Panels and brackets

Lightweight body panels, engine parts, and aircraft components

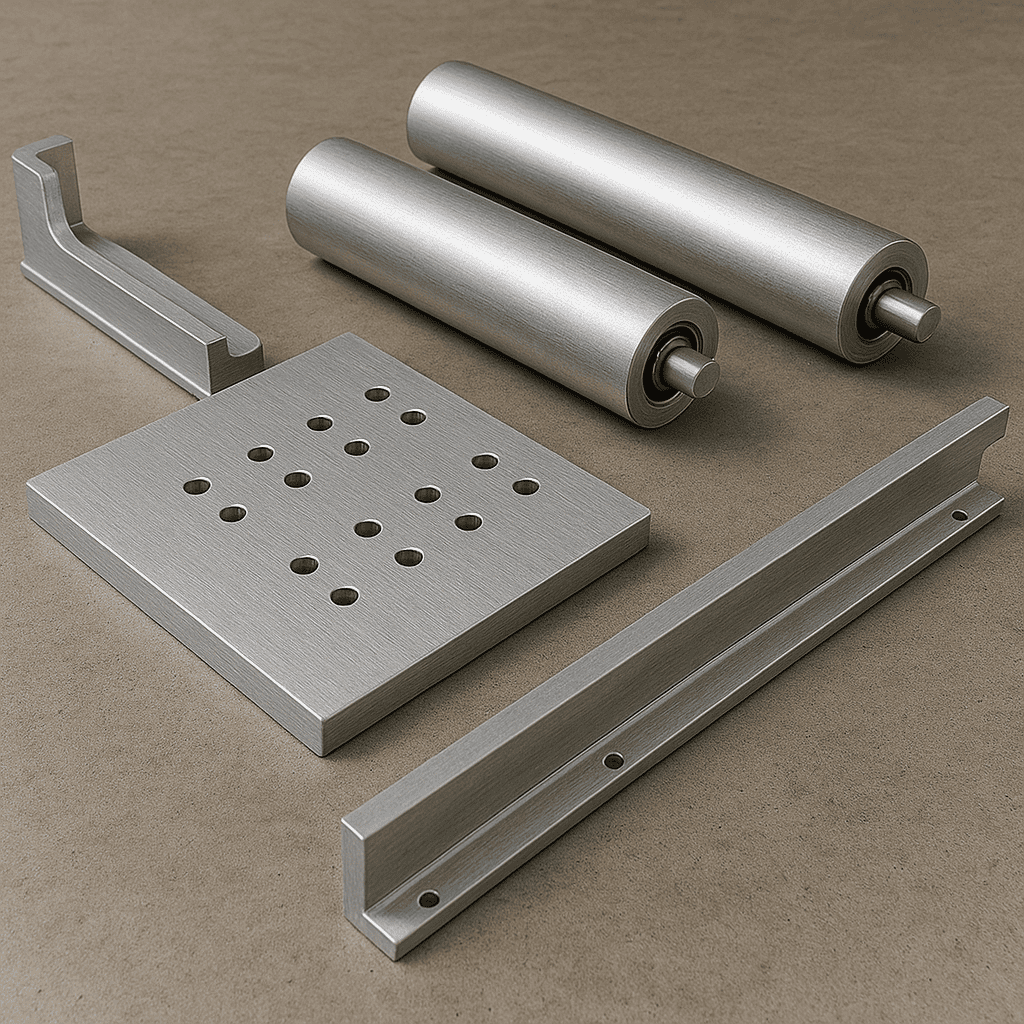

Conveyor parts

Fixtures and tables

Enclosures

Customized fabrication

Why Cyclotron Industries Is Your Trusted Aluminium Fabricator In Pune

When you partner with Cyclotron Industries, you get more than a fabrication supplier. You get a team that takes complete ownership of your project from start to finish.

Full In-House Setup: You don’t have to coordinate between multiple vendors for different fabrication processes. Everything happens under one roof. With our in-house developed welding tables, precision tools, and advanced fabrication systems, our engineers handle the full cycle of your product. This means better control, fewer communication gaps, and higher accuracy.

Here’s Why Our Customers Choose Us

- A highly experienced fabrication team that understands engineering details

- Advanced equipment and technology for precision cutting, welding, and finishing

- Inspection tools and quality checks at every stage of production

- End-to-end aluminium fabrication and finishing completed within our facility

- Engineering assistance for custom fabrication and design improvements

- Local technical support and on-time delivery in Pune and nearby industrial zones

- Our approach combines technical skill with reliability, which is why many OEMs and manufacturers continue to trust

Cyclotron Industries as best Aluminium fabricator Pune because of our technical capability and consistent results. - Quality & Inspection: Quality has always been the core of Cyclotron Industries. Every part that leaves our facility goes through a series of strict inspections and quality control checks to make sure it meets the standards our clients expect.

- Dimensional Accuracy Verification: All aluminium fabrication components are measured using calibrated tools and precision gauges to ensure they meet specified tolerances.

- Weld Quality and Strength Inspection: We carry out both visual and technical inspections to check weld penetration, uniformity, and strength.

- Surface Finish Checks: Our team makes sure that every finished surface, whether powder-coated, anodized, or brushed, is clean, consistent, and free from defects.

- Technology Integration: We keep updating our process with new technologies and fabrication methods to improve efficiency and reduce waste.

- Consistent Improvement: Based on feedback from our clients and performance data, we keep refining our process to achieve better quality and faster turnaround times.

Project Execution Process in Aluminium fabrication

At Cyclotron Industries, we believe that a well-defined process leads to better results. Our workflow ensures right project execution, consistent quality, and timely delivery.

1. Design and Drawing Review: Once you share your drawings and requirements, our engineering team studies every detail, including tolerances and manufacturability. If required, we also suggest design improvements to enhance strength or reduce production costs.

2. Material Procurement: We choose aluminium grade alloys based on your requirements and source certified aluminium sheets and profiles from verified suppliers.

3. Fabrication and Assembly: Using CNC laser cutting machines, bending tools, and in-house welding systems, we produce robust aluminium components that align with your design intent.

4. Inspection and Finishing: After fabrication, we conduct thorough dimensional checks, weld inspections, and surface finishing quality to ensure the highest quality output.

5. Delivery and Installation: Once approved, products are carefully packed and shipped. For large assemblies, we can assist with installation and alignment at your site.

This clearly defined workflow gives our clients confidence that every fabrication project will be completed correctly, on time, and without unnecessary complications.

Aluminium Grades We Work with for Aluminium fabrication

Not all aluminium is the same. Each grade has unique properties desired for specific applications. At Cyclotron Industries, we work with several common aluminium alloys that cover a wide range of requirements.

| Aluminium Grade | Properties | Applications |

|---|---|---|

| 5052 | Exceptional corrosion resistance, medium strength, easily formable | Marine applications, enclosures, and architectural parts. |

| 6061 | High strength, weldability, and machinability. | Machine frames, support structures, and automotive parts. |

| 6082 | Strong, weldable, smooth surface finish | Industrial equipment, jigs and fixtures. |

| 7075 | Very high tensile strength, lightweight | Aerospace applications, tooling, and performance assemblies. |

How do you benefit from Cyclotron?

Reduced Lead Times

With all fabrication processes handled in-house at Cyclotron Industries Pune, dependency on external vendors is minimized, resulting in faster turnaround.

Low or No Rework

Handling the entire process under one roof ensures first-time quality, reducing errors and minimizing rework.

Repeatability

With modular welding tables, welding automation, and advanced equipment, we make sure every batch comes out with the same consistency. Parts fit together the way they should, without you worrying about variations.

Simplified Supply Chain

Managing the complete process internally simplifies the supply chain. With PAN India delivery, your parts arrive safely and on time, while you focus on other aspects of your business

Final Thoughts

Custom fabrication is not just about owning equipment; it’s about controlling the process. From fixturing to design execution and clear communication, every step is customized to your project’s requirements.

While Pune provides a thriving industrial ecosystem, Cyclotron combines the knowledge of a toolmaker with the expertise of a fabricator. This unique combination ensures highly precise welding products with repeatability, reliability, and efficiency.

If you are seeking custom fabrication services in Pune, Cyclotron Industries is a reliable and technically capable partner for your projects.

Our clients

FAQs about fabrication services

- What is your lead time? We generally offer a standard lead time of 7-8 days.

- Do you handle urgent prototypes for fabrication? Yes we do offer services which you weld your metal parts within a day.

- Which materials are in stock? We generally keep materials like MS and SS in stock with sheet thickness of 3mm, 6mm, 8mm, 12mm, 16mm.

- Do you provide the quality reports after cutting? Yes we do have a PDI inspection report which we provide after each batch.